OUR MISSION

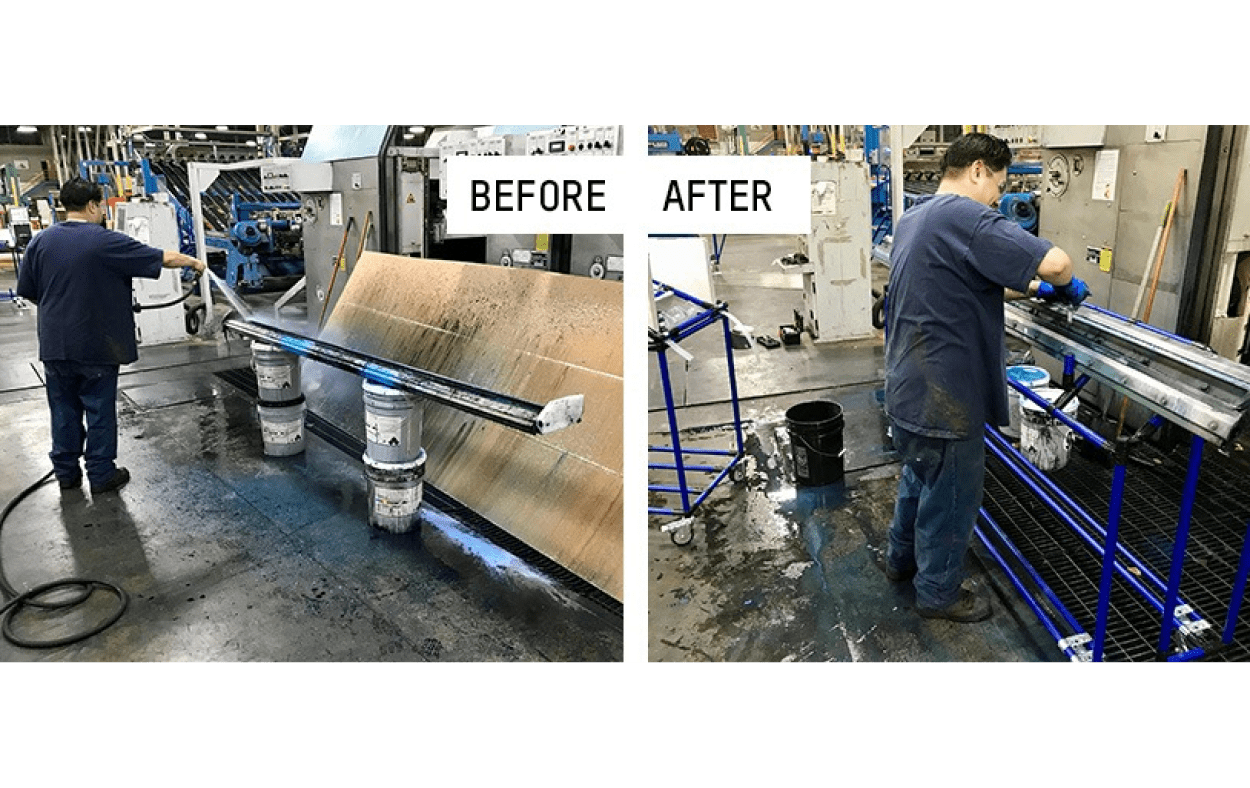

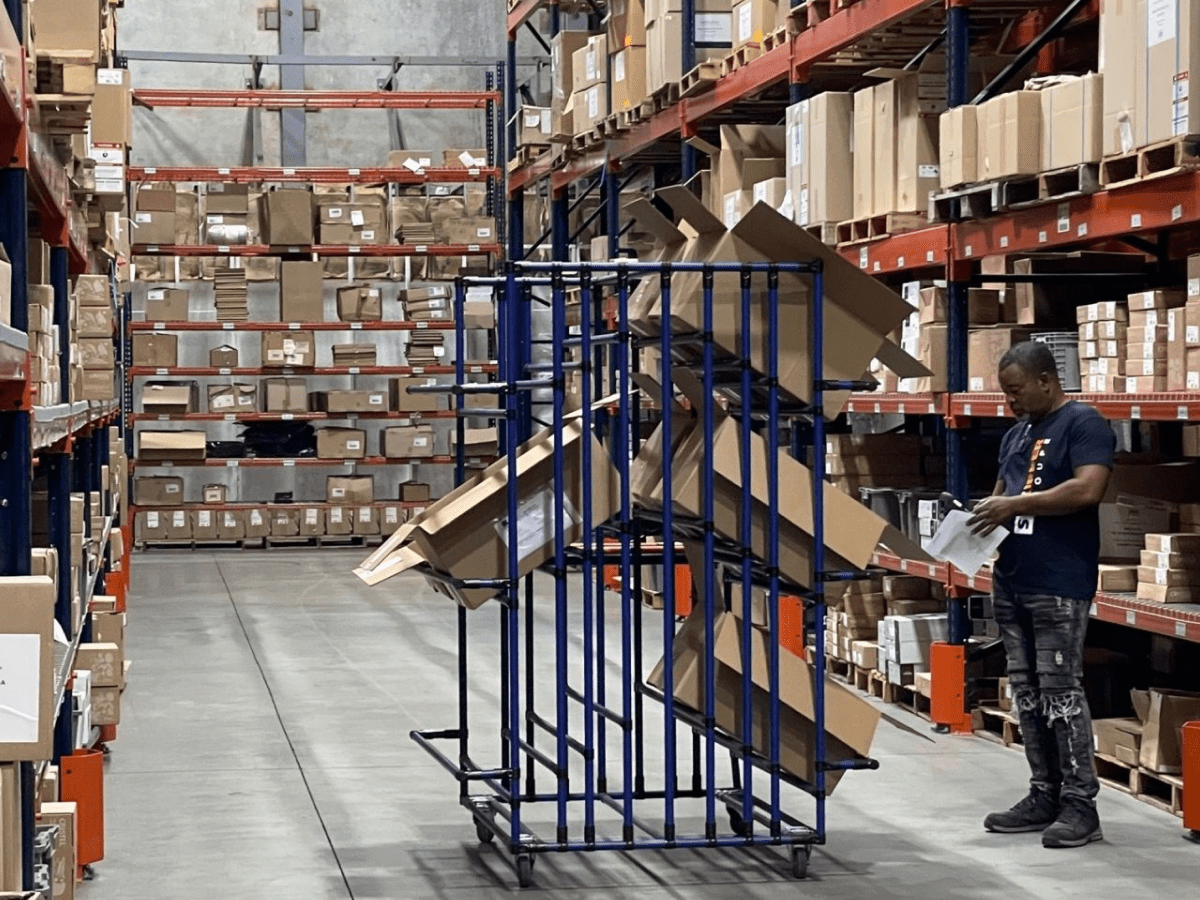

We aim to enable individuals and companies to increase their productivity and add value to their processes.

Into business

We act to equip workers and companies to use their creativity to organize their environment and facilitate their work. The simplicity of the assortment offered allows users to be creative, autonomous, and to continuously improve their constructions.

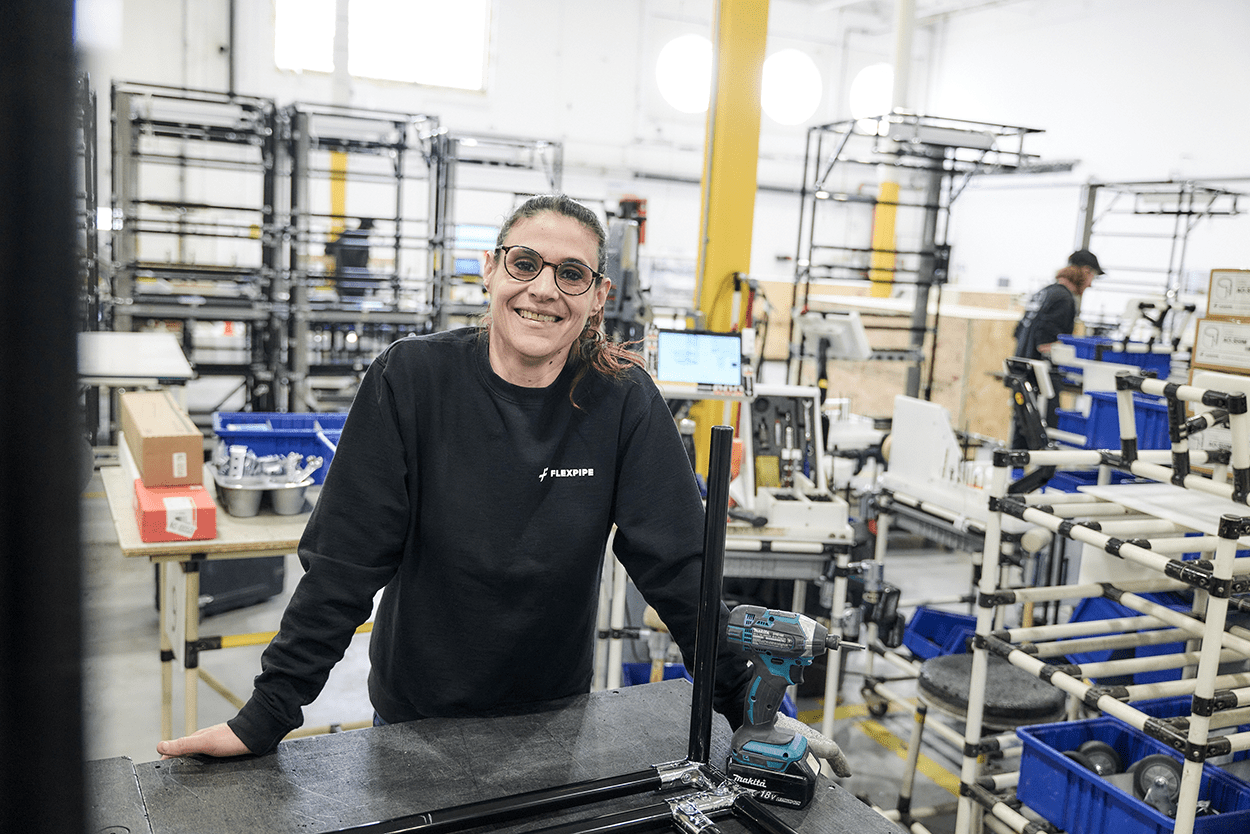

Into human

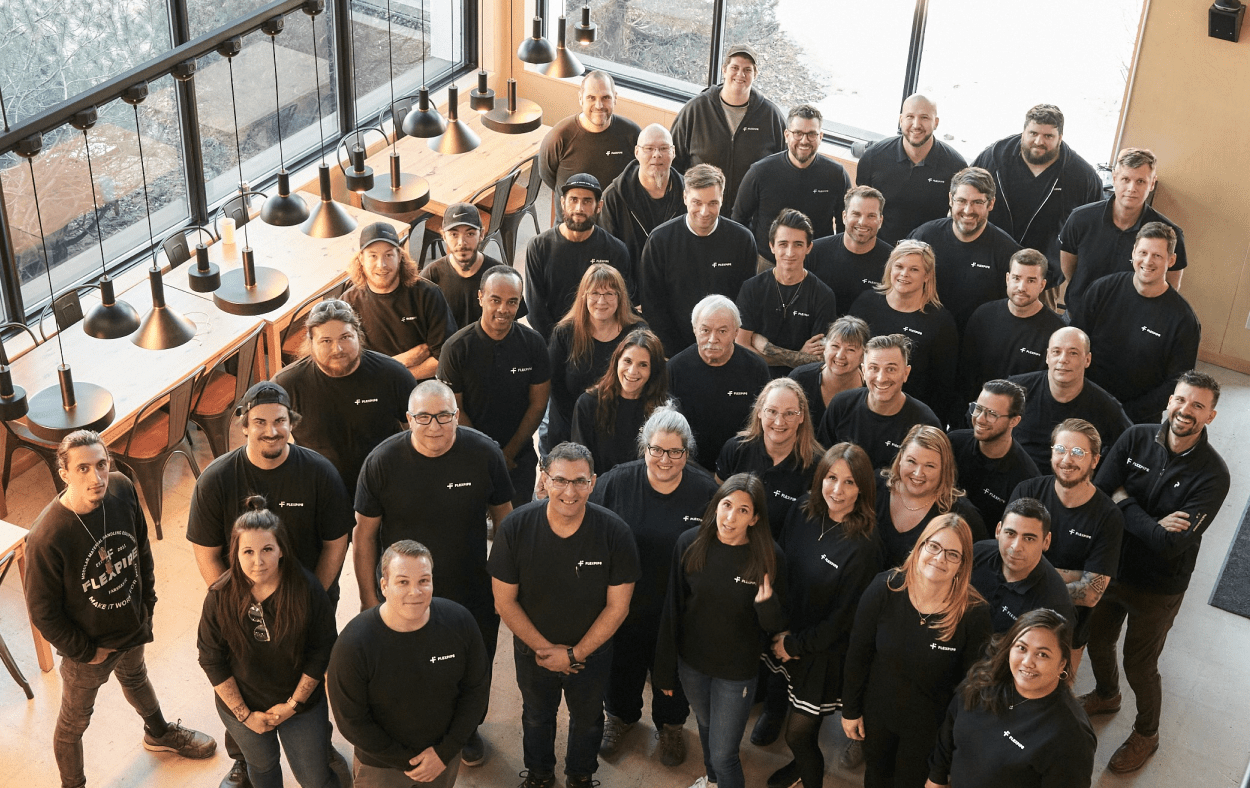

We ensure that employees are proud to surpass themselves and contribute to the growth of the company. We promote development through continuous training and the well-being, health, and safety of staff in a welcoming and inclusive atmosphere.

Into community

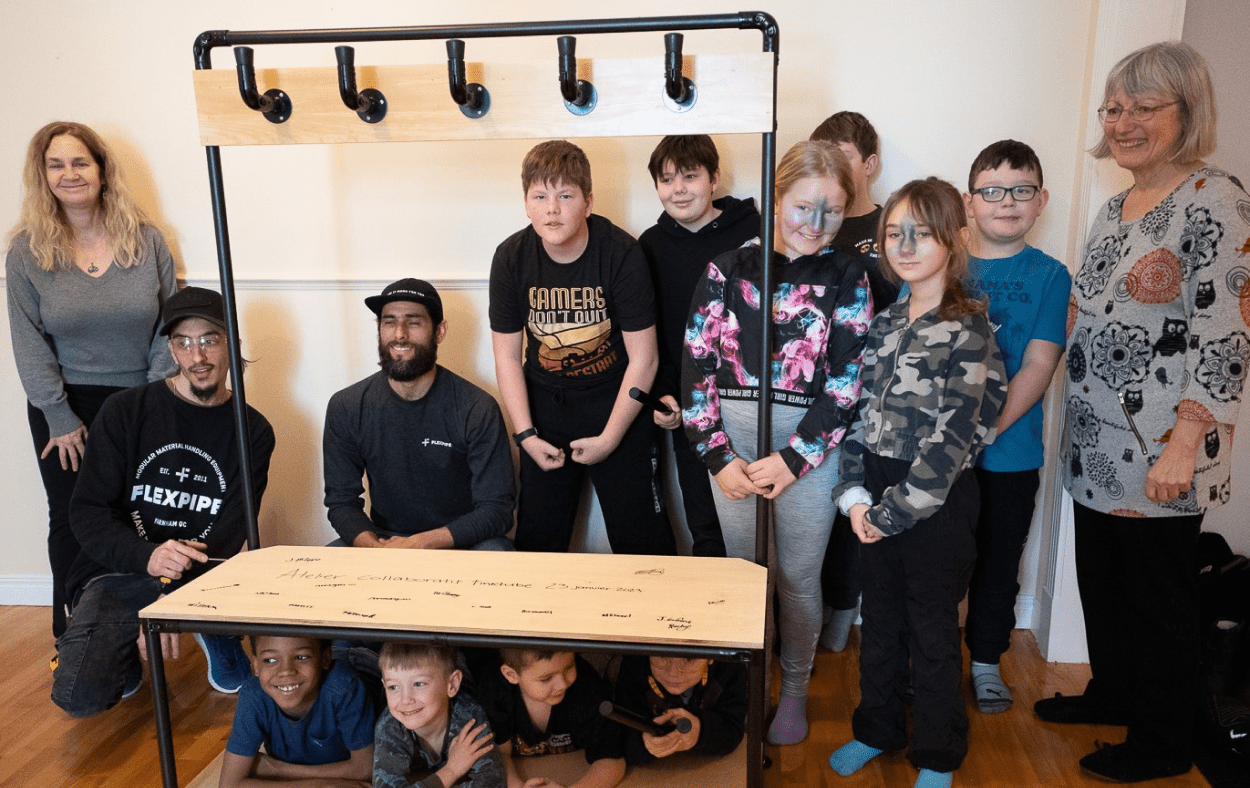

With our product, our know-how, and our time, we get involved in local initiatives and support important social causes related to education, dropping out, and social reintegration.

“Whenever I need to change or rush an order you are always receptive or positive even if you cannot make it happen. We appreciate the good customer service.”

Shawn Lewis, I.C.E. Manufacturing LLC

OUR VALUES

At Flexpipe, the 5 great company values are at the center of all our actions for more than 10 years.

Customer Satisfaction

- The internal customer and the external customer are a priority

- We do our best to meet our customers’ expectations for time, service, and quality

- We make life easier for our customers

Excellence

- The search for excellence is an endless quest

- Our efficient work results in the continuous improvement

- Accomplish the best with the fewest resources possible

by simplifying our work and that of others

Friendliness

- We are looking for good understanding, pleasure

and mutual aid - We value pleasant, warm, and personal relationships

- We personalize interactions and process each person as unique

Integrity

- We are honest, faithful, dedicated, and fair

- We recognize our strengths and successes, but also our mistakes

and our weaknesses - We give an accurate picture; all information is communicated

Reliability

- Rigor and consistency are two constant forces

- We make commitments and we keep them

- We are accountable to those affected, and we correct our mistakes

OUR PROMISE

SIMPLE, ACCESSIBLE AND ECONOMICAL!

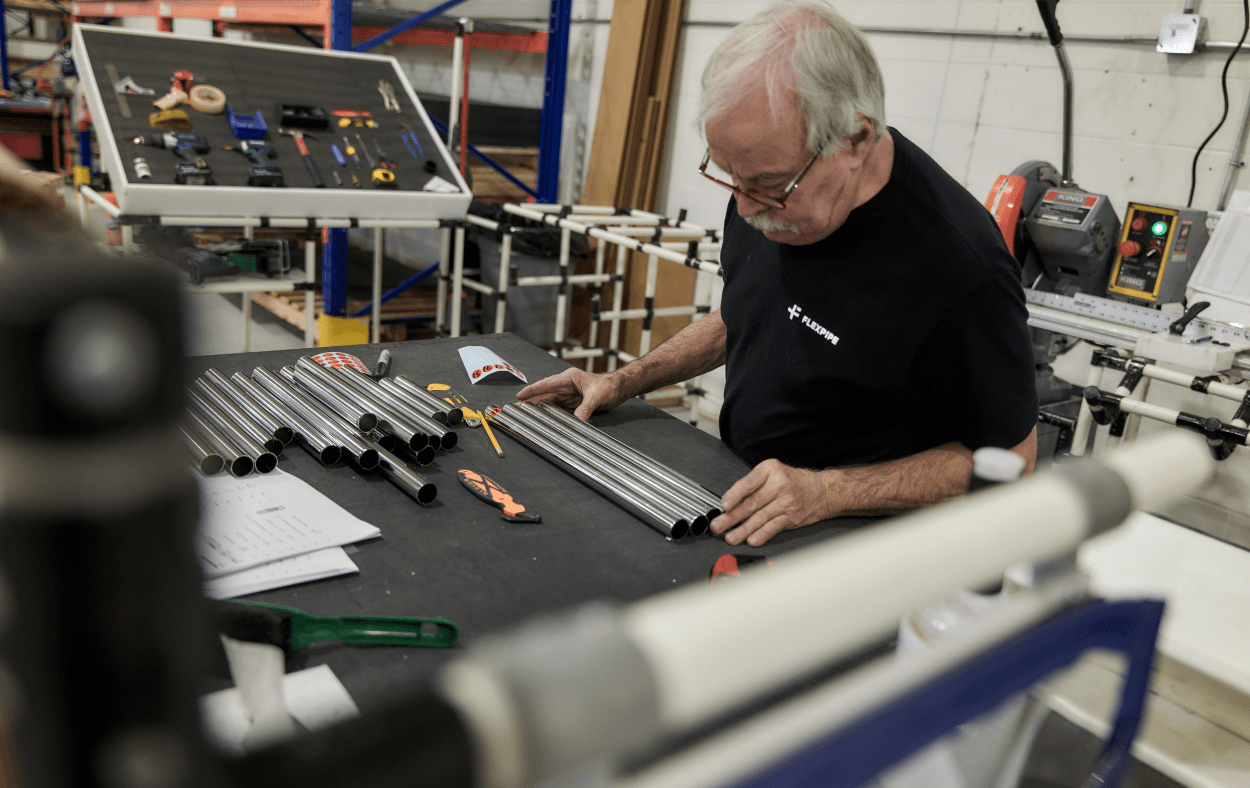

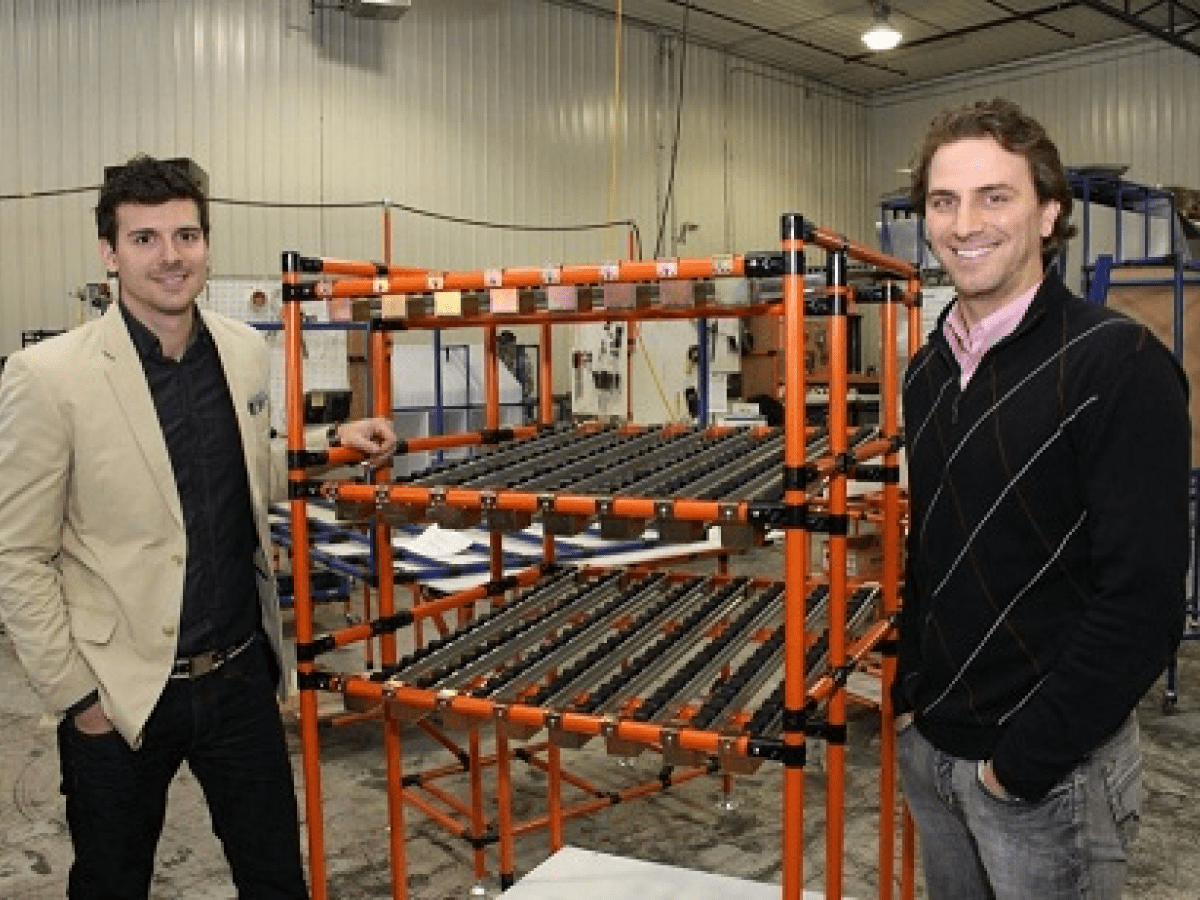

For more than 50 years, the modular system has proven itself in lean manufacturing on the market, particularly in the automotive and aeronautical manufacturing industries. For more than 10 years, we have been committed to making the modular handling system for tubes and connector joints accessible to companies in North America, and beyond!

We strive to always find better working methods to offer you:

- The best value for money

- A simplified modular system accessible to all

- The best tools to stimulate your creativity and allow you to be autonomous

OVER THE YEARS

2023

80/20 Partnership

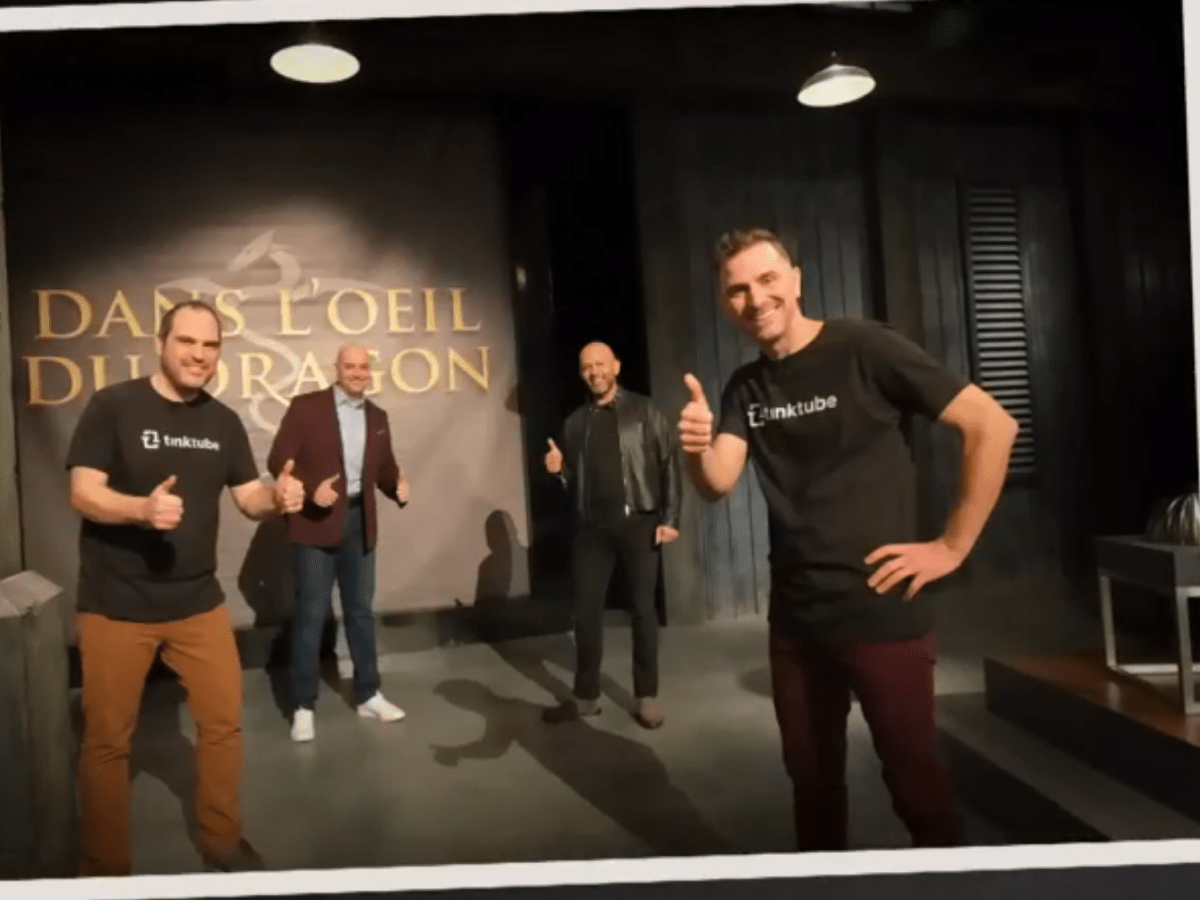

2021

FP celebrates its 10th anniversary!

2020

tinktube’s Launch

2019

Distribution Center in California

2018

Distribution Center in Georgia

2016

Company creation

WE ARE COMMITTED TO OFFERING YOU

THE BEST SERVICES

Learn more about the 9 services offered by Flexpipe

to maximize your production line.