Technical Data

HOW TO CALCULATE THE LOADING CAPACITY FOR MODULAR STRUCTURES

How to build

HOW TO BUILD MODULAR CARTS

Post

MATERIAL FLOW : A KEY ELEMENT IN CIRCULAR MANUFACTURINGCarrying and storing heavy loads with carts is common in the manufacturing environment. At Flexpipe, we have two approaches to the base of these carts, square tubing and 2mm lined tubing. Both have their benefits but let’s focus on the most versatile option: the square tube.

Estimated reading time: 8 minutes

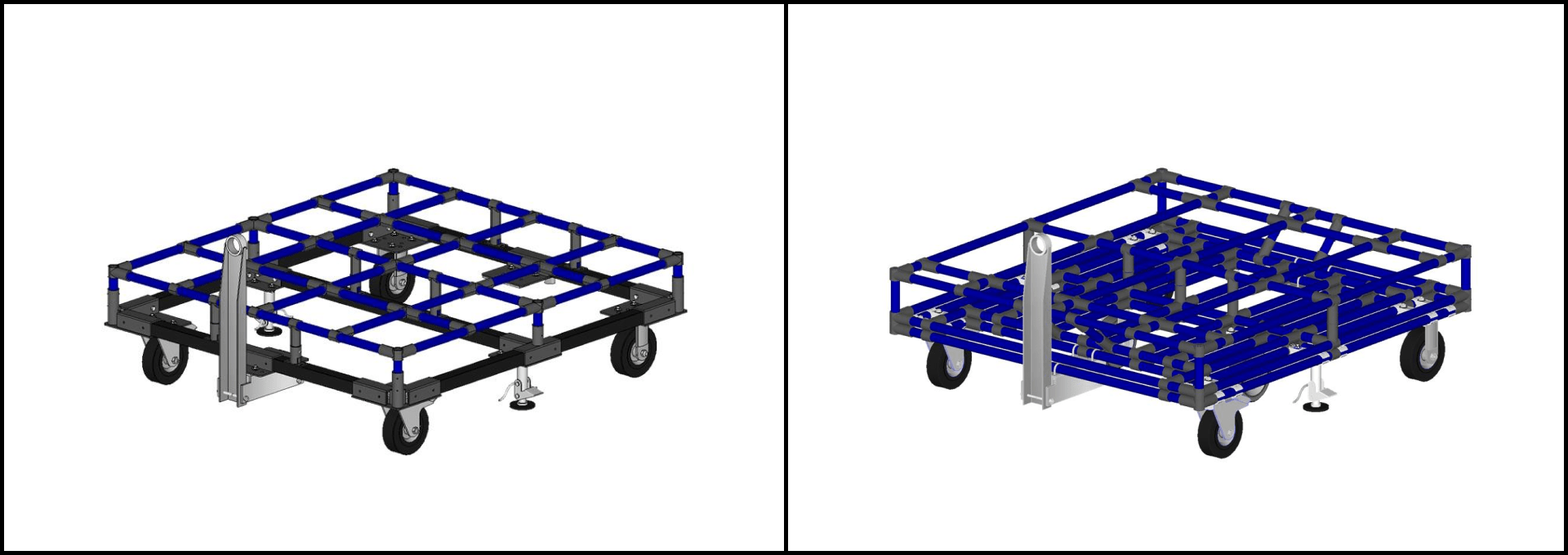

Square Pipes are a simple, cost-effective, durable, and robust solution for companies looking to increase the strength of their base on tuggers or other heavy-weight structures. Accompanying the Square Pipes are several ancillary support products such as corner plates, center plates, tow bars, tow bar connectors, heavy duty wheels, and forklift adapters.

Circular steel tube and joint systems have been on the market for over 50 years. The industry settled on a standard width for circular steel pipes long ago. Regardless of what circular piping you’re currently using, it’s simply not an ideal solution as a base for tug carts or heavy-weight structures.

The Square Pipe was designed for those situations where customers want to lift or transport tug carts or structures using a forklift. Despite the high strength and load-bearing capacity of round pipes, heavy loads would lead to deflection as the weight of a tug cart would be focalized to the width of the forklift’s pallet forks.

Finally, the 2mm round tube will reach its highest yield point before bending, which is why square tubes are the preferred option for heavy loads and forklift transport.

Square Pipes are less affected by shocks, impacts, or blows from forklifts. The Square Pipes and the corner and center steel plates provide a more solid, stable, and rigid solution for tug cart bases.

Our HD wheels are the perfect complement, allowing quick and easy assembly. Forklift Adapters – or forklift guide plates – have a universal width capable of supporting the four-to-six-inch width of all pallet forks on forklifts.

Tow Bars and Tow Bar Connectors allow tug carts can be pulled by a battery-powered, motorized, or electric tugger or manually moved as a single structure.

Ultimately, the Square Pipes with the corner and center steel plates make the base of your tug or heavy-weight structure as solid, durable, and strong as a welded structure. However, with the Square Pipes, you can easily modify the base of your tug cart in terms of its length and size without the hassles of cutting, re-sizing, and re-welding.

The best time to consider the use of square pipes is during the initial design stage of your structure. If the carts you design will be subject to vibration and intended for transporting parts between plants or work cells, square pipes should be a priority. Using them early in the assembly of your cart ensures that your structure is safer for operators and technicians, and has the load capacity to move heavy loads.

An additional benefit of the Square Pipes is the product’s ability to be reused for heavier structures. Tug carts often travel long distances within warehouses, production locations, or adjacent warehouses and production plants. The sturdier base ensures a more effortless movement and transport of tug carts.

In some cases, it may be more advantageous to use a 2mm lined base. It all depends on the loads that your tow truck or heavy structure will support. Calculating these loads is the most important step in designing your modular and scalable structure.

The table below allows us to compare the price of carts made with a square pipes base and the other with a lined base. You will quickly notice that the square pipes is slightly cheaper in price but far superior in strength. However, the use of your cart should be the biggest variable in your decision.

| Flexpipe part Number | Quantity 2mm | Quantity Square pipe base | Unit Price | 2mm Total | Squarebase Total |

| AP-ICAP | 4 | 0 | 0,16 $ | 0,64 $ | 0, 00 $ |

| BC6 | 2 | 2 | 37,98 $ | 75,96 $ | 75,96 $ |

| CO-SLF | 1 | 1 | 189,00 $ | 189,00 $ | 189,00 $ |

| CO-SLM | 1 | 1 | 59,50 $ | 59,50 $ | 59,50 $ |

| HJ-1 | 62 | 16 | 1,73 $ | 107,26 $ | 27,68 $ |

| HJ-2 | 12 | 4 | 2,67 $ | 32,04 $ | 10,68 $ |

| HJ-3 | 4 | 2 | 3,90 $ | 15,6 $ | 7,80 $ |

| HJ-4 | 19 | 9 | 2,60 $ | 49,4 $ | 23,40 $ |

| HJ-9 | 0 | 6 | 2,59 $ | 0, 00 $ | 15,54 $ |

| SQS-CENTERP | 0 | 2 | 26,04 $ | 0, 00 $ | 52,08 $ |

| SQS-CORNERP | 0 | 4 | 32,55 $ | 0, 00 $ | 130,20 $ |

| SQS-HPLATE | 0 | 2 | 36,89 $ | 0, 00 $ | 73,78 $ |

| W-6PF-HD | 2 | 2 | 69,00 $ | 138,00 $ | 138,00 $ |

| W-6PSB-HD | 2 | 2 | 99,00 $ | 198,00 $ | 198,00 $ |

| SQP-96-BK | 0 | 3 | 45,00 $ | 0,00 $ | 135,00 $ |

| P-96-BL | 6 | 5 | 10,51 $ | 63,06 $ | 52,55 $ |

| M8-45B | 24 | 0 | 0,20 $ | 4,80 $ | 0,00 $ |

| M8-N | 24 | 0 | 0,07 $ | 1,68 $ | 0,00 $ |

| W-6PF | 2 | 0 | 24,41 $ | 48,82 $ | 0,00 $ |

| WF-LARGE | 24 | 0 | 1,36 $ | 32,64 $ | 0,00 $ |

| SP-96-BL | 12 | 0 | 16,91 $ | 202,92 $ | 0,00$ |

| F-W5/16 | 48 | 0 | 0,05 $ | 2,40 $ | 0,00 $ |

| Time (hours) | 5 | 2,5 | 20,00 $ | 100, 00 $ | 50,00 $ |

| Grand total: | 1321,72 $ | 1239,17 | |||

| Difference % | 6,25% |

While normal pipes can be cut with a circular, miter or bench saw, for the Square Pipes, it’s best to secure the pipes in place and cut them with a stationary band saw. The Square Pipes are larger, wider, and stronger than the round pipes. As such, without them being secured in place, you risk them jumping, sliding, or skipping, which can lead to an uneven cut and injury. Finally, there is a bit more preparation and deburring after cutting Square Pipes than circular pipes.

Flexpipe’s entire team is committed to helping you adopt lean manufacturing principles while reducing your costs of material handling. Flexpipe scalable and modular tube and joint systems allow companies to customize their material handling structures to simplify workflow, material flow, and material handling while optimizing shop floor square footage.

For insight into how Flexpipe’s team can help, contact us now.