Post

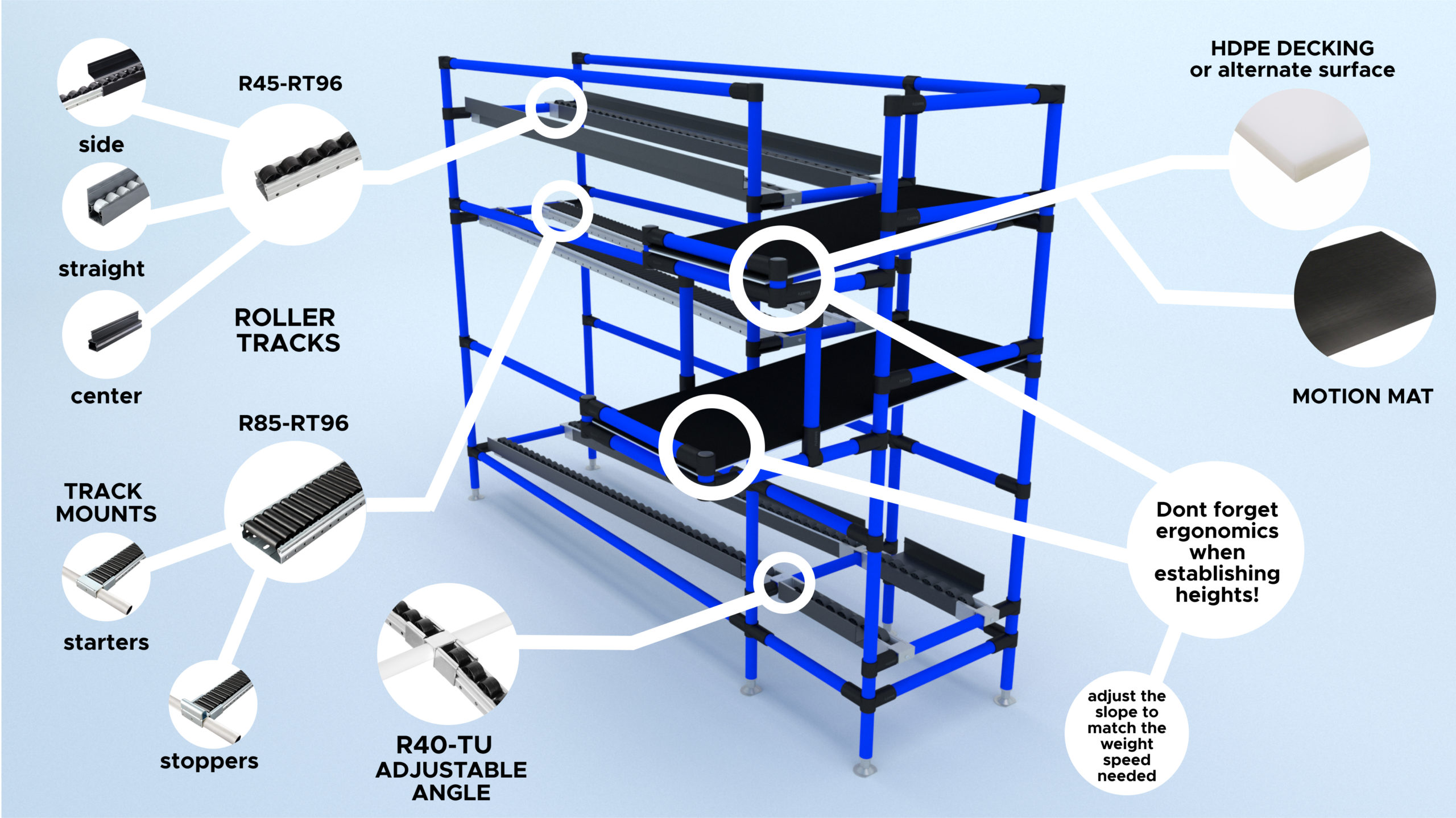

SUPERMARKET FLOWRACKS AND THEIR INFLUENCE ON MANUFACTURING

How to build

FLOWRACK ASSEMBLY TIPS

Post

THE 10 STEPS FOR A SUCCESSFUL PROJECTAn L-shape flow-rack is ideal when adapting to tight spaces where every inch counts

Use the following checklist to build the ultimate L-shaped flowrack exactly the way you need it!

Keep in mind to consider the weight and shape of your item in order to establish the right slope

Reading time 5-7 minutes

3-4h

3-4h

This is all about utilizing all of the production floors as efficiently as possible to meet employees’ specific needs.

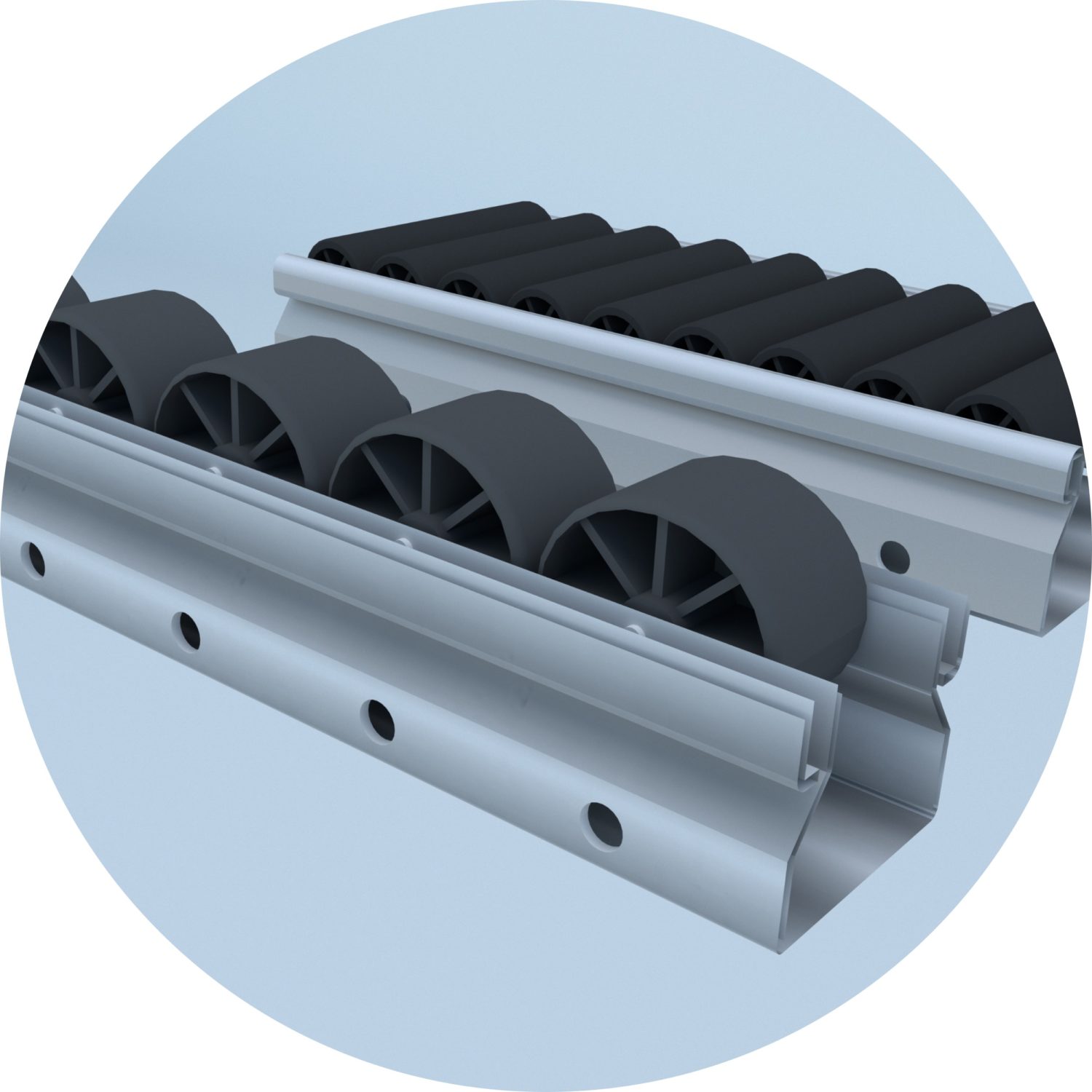

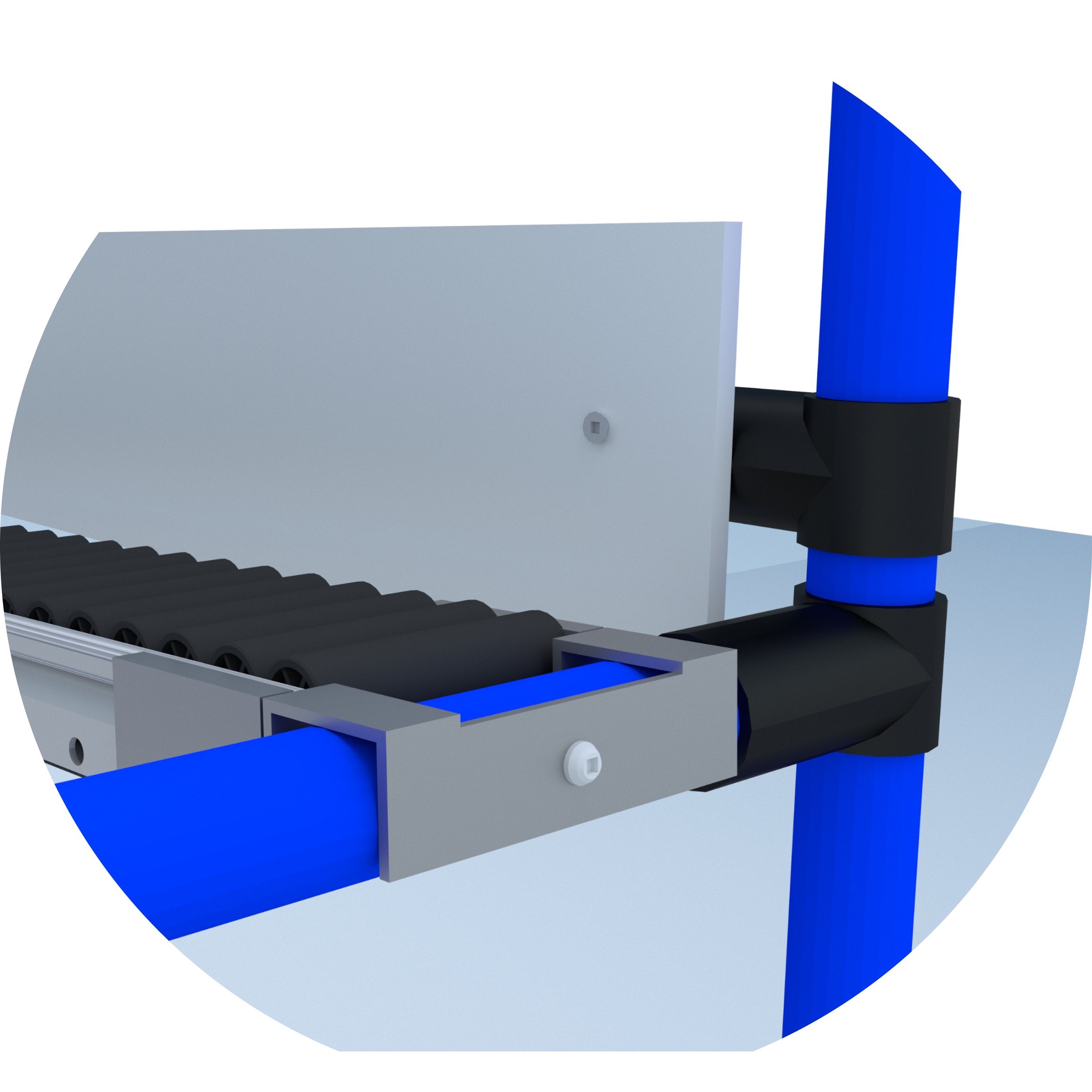

You can choose from the R40-RT96 standard roller track or the R85-RT96 wide roller track.

It all depends on the weight of your part, box, or item

Let’s think of the R40-RT96 track as an economic all-around kind of track that can be applied

in many different scenarios and has proven to “hold its own”

Whereas the R85-RT96 might be geared more for medium to heavy-duty items and

more specialized flow-racks where it may demand a wider track to carry larger amounts of weight

Or perhaps an odd-shaped part that sits better on the wider track

Also, consider the distance it will travel. Think of adding horizontal support along with

a track mount stabilizer as the span gets longer to correctly support items as they travel down the tracks

And lets’ not forget the longer the distance between the two, the greater the slope’s incline will have to be

So the container’s starting point will be very high up and its destination, very low

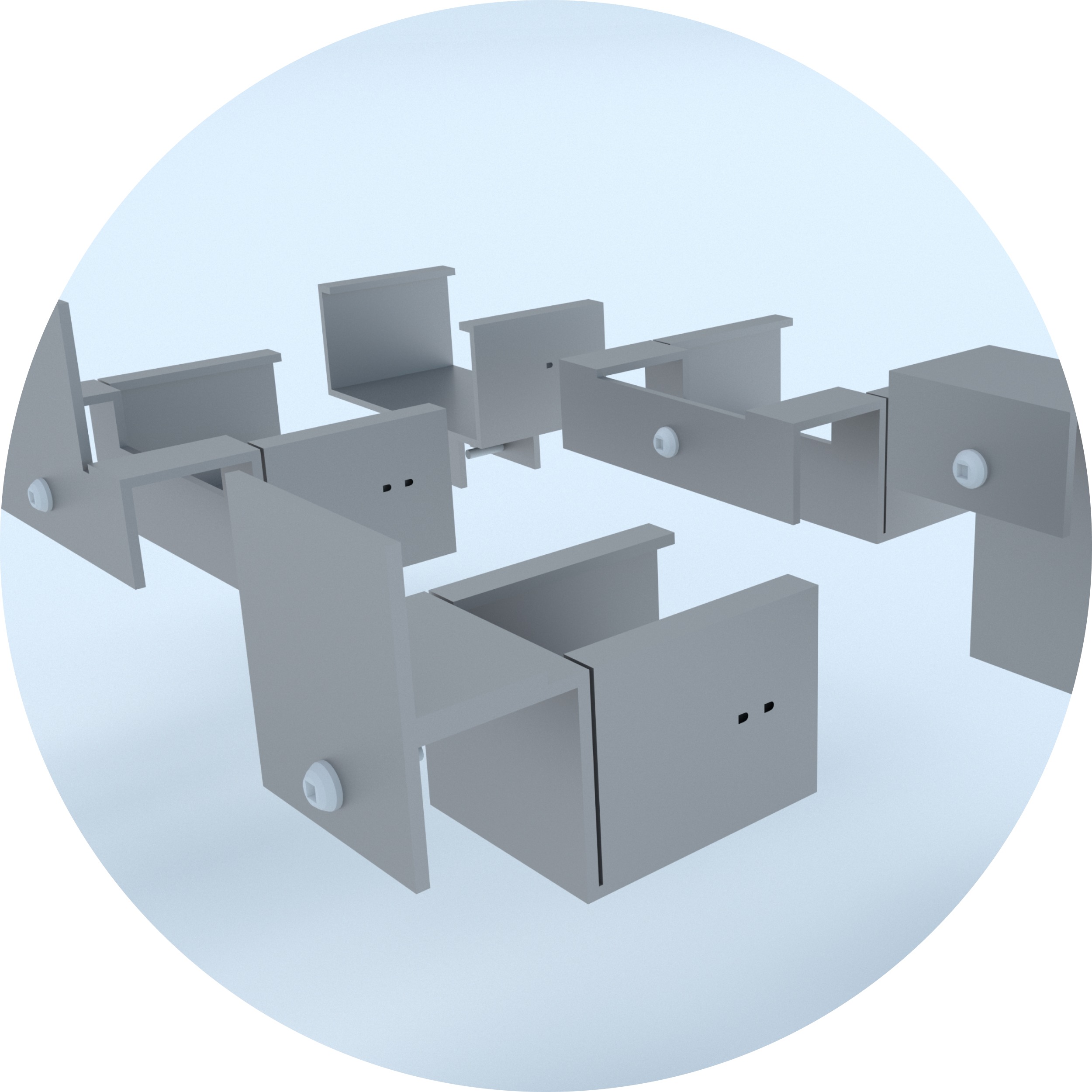

Depending on the type of roller track you choose you will have different options

but generally speaking, you need a starter mount and a stopper mount

Another option is to create your own stopper by doubling up the pipes

(something to consider if you are low on inventory and need to get the job done).

Whether you choose plastic guides or to make your own the idea is the same

” Keep parts in place while in motion”

Add a strip to the side and create your own to fully customize your flow-rack

Any surface will do so long as it covers the span of your track

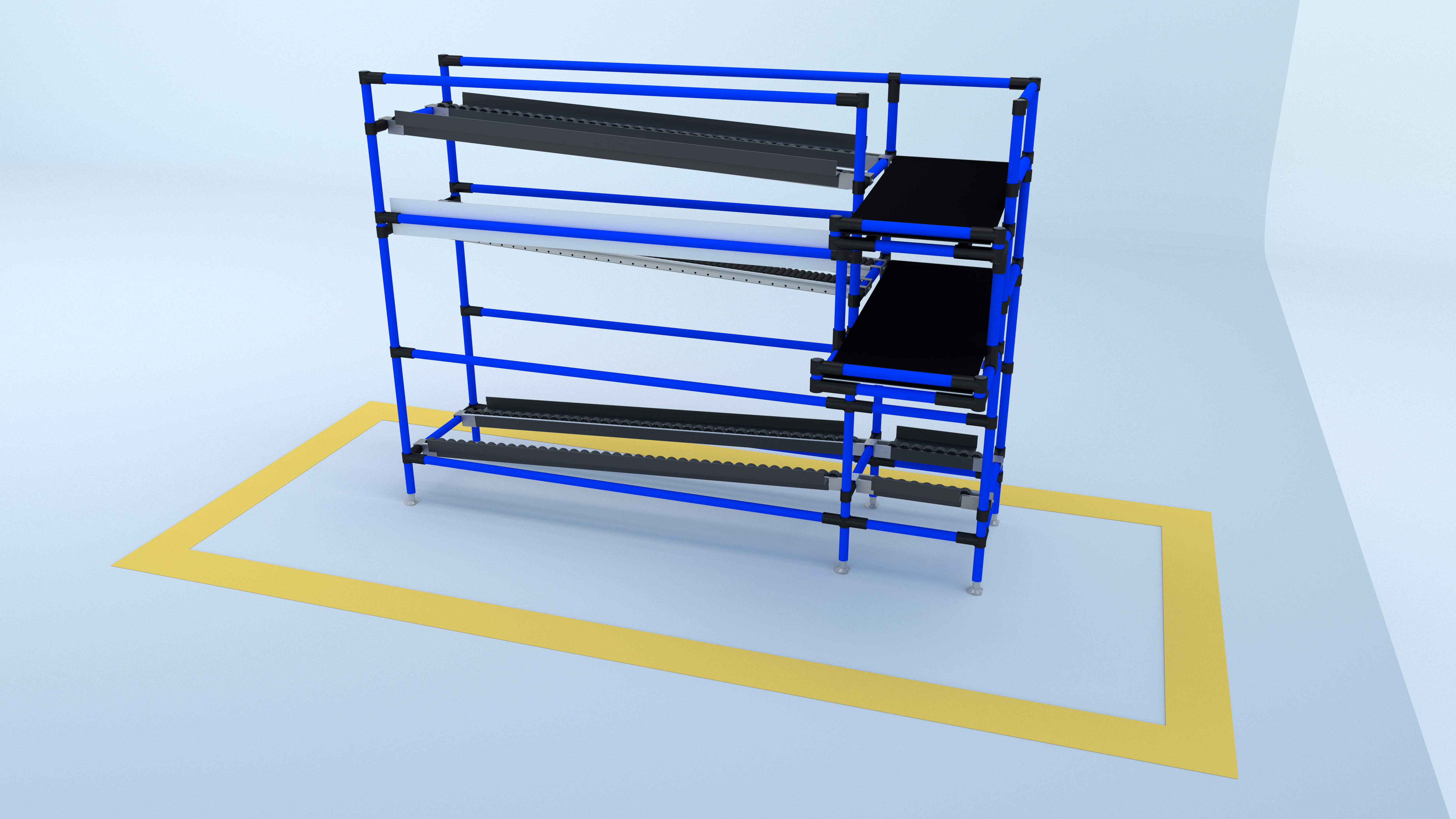

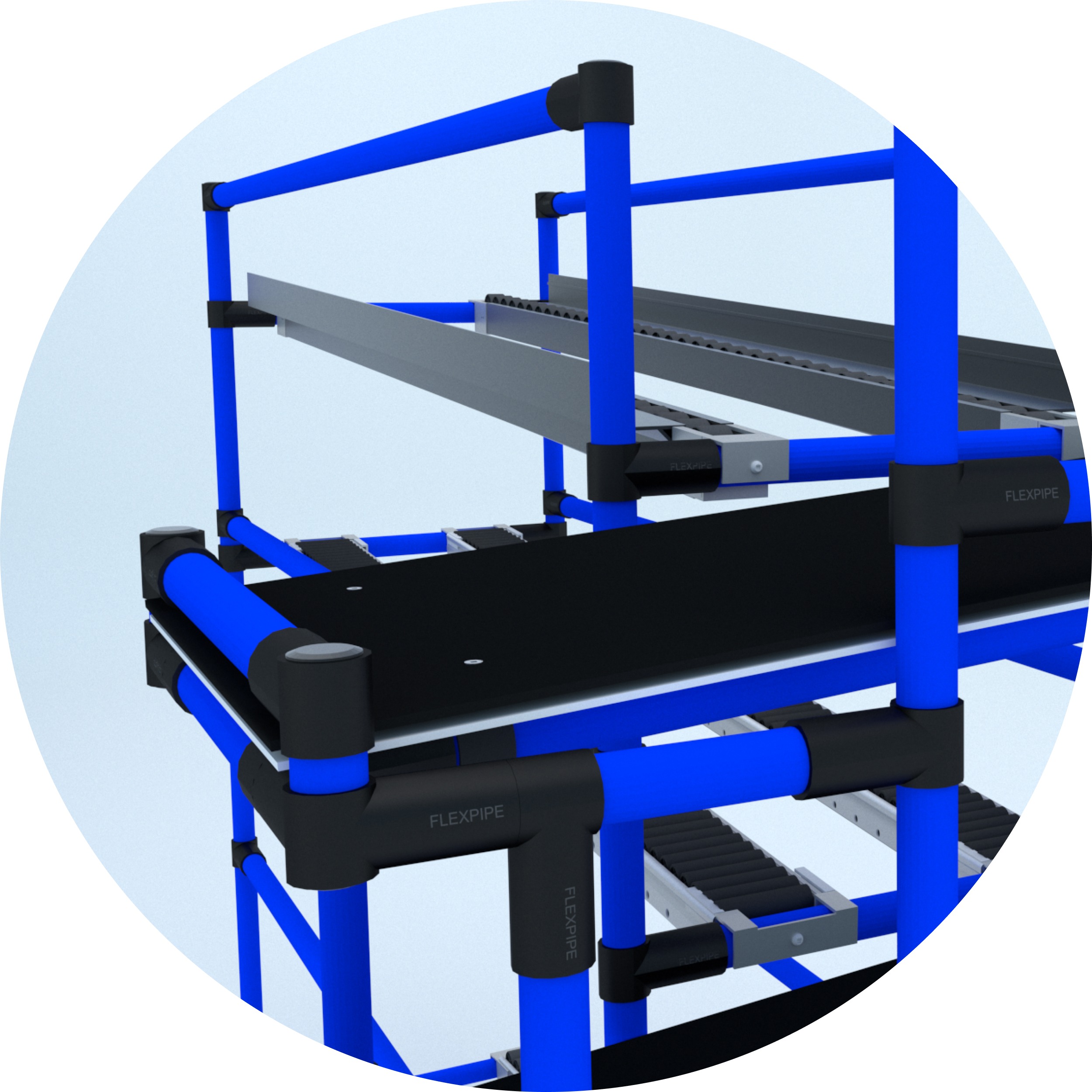

here is a great example of a model drawn in Sketch-Up using the creator extension

An L-shaped is all about changing direction while in motion and

this is where adding a surface can be advantageous, as the added

surface area allows for any part, bin, or box to transition and land safely

A typical set up combines a 1/4″ HDPE (surface) with a 1/8″ Motion Mat on top

the idea is to create a slope steep enough for it to slide down to the stopper

For this type of application, you can screw from the top

through all of the surfaces, ao-shim, and pipe

using a flat-head decking screw to finish flush with the surface

Let’s not forget the vital role that ergonomics play when building a custom flow-rack

The input of the individual who will be using this L-shaped flow rack is absolutely necessary

in order to create the best possible environment for workflow and overall employee satisfaction

The sooner you get the structure on the floor

the sooner you get the feedback from the employees

the sooner you can modify, adjust, and fine-tune the design

Here are great examples drawn in Sketch-Up using the creator extension