Post

TOP 6 TOOLS FOR CUTTING

How to build

MODULAR CART ASSEMBLY TIPS

Page

ON-SITE TRAINING

Assembling a Flexpipe structure can be an easy process and can be made even quicker if you use the appropriate tools. All Flexpipe joint sets are assembled with the same nuts and bolts. As such, you’ll just need a 5-mm hex head tool to carry out your project.

Depending on the scope of the project, it’s essential to know which tool can save you the most time and money. Here’s a list of the five tools we recommend, with their respective pros and cons.

Estimated reading time: 4 minutes

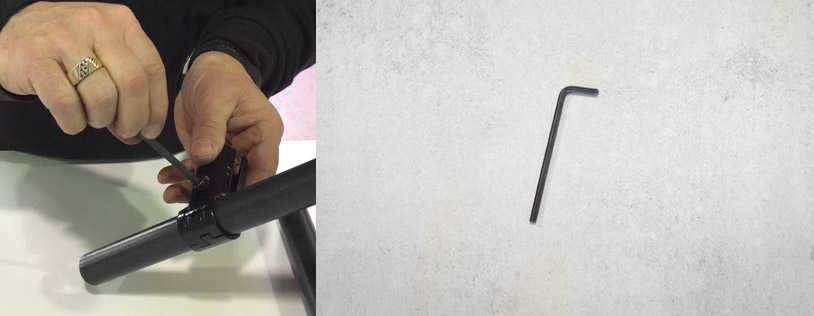

The hex key, or Allen key, is found in most toolboxes. This inexpensive tool, which is available in many stores, is perfectly adapted to carry out adjustments on existing structures or to build small projects. The hex key’s modest size enables you to work in those hard-to-reach places that other tools are unable to access.

TIP: Did you know that you can cut a long hex key into several pieces? These pieces can subsequently be used as a hex head on your drill. However, this tip does not work for impact drivers.

We don’t recommend using a hex key for assembling larger projects, as this may be painful for your hands and wrists. While the hex key is convenient, it’s not intended to be a time-saver.

A hex socket wrench is a useful, light tool. One can choose a 5mm (1/4’’) unit with a preset cutting range of 2-100 inches per pound (9.8 Nm). This cutting range is the ideal strength to assemble Flexpipe structures. As such, your bolts will always be correctly tightened.

TIP: You may find it challenging to locate this preset tool, so we’ve done the searching for you! The tool is available for purchase on seekonk.com (US-based, delivery to Canada is possible).

While this tool is faster than the hex key and the T-handle, you’ll find others listed in this article that are quicker to use. You should keep in mind that a preset torque wrench is not a standard tool, and it can be challenging to find; it can be expensive, too.

If the one you are using is not preset, you’ll need to pay close attention to the torque setting. If it’s too tight, the bolt heads may become stripped, and you won’t be able to use the bolts again in future projects.

A cordless drill is a highly useful tool for projects that only require short assembly time. Given that most people have already used a drill, little employee training is necessary. Furthermore, you probably have one on hand in your facility!

It’s essential to adjust a drill before using it. You must select the “V1” speed setting: that is, the drill speed will be moderate, but with a high level of power. Failure to adequately set the speed level can lead to a wrist injury.

Also, be ready to compose with the tool’s weight when assembling a large-scale project. Speed is critical here; make sure you have the right torque setting, so you don’t strip the bolt heads and render them unusable for future projects.

As a useful complement to the impact driver, the T-handle hex key is handy to tighten bolts, which are hard to reach. Its rubber grip makes it more ergonomic and comfortable than the hex key, and it is also very affordable.

As is the case for the hex key, this tool is not suitable for large-scale projects. If you do choose to use it, nonetheless, it may be painful for your hands and wrists. While it won’t provide the quickest execution time, the T-Handle hex key can prove to be useful in certain situations.

The impact driver, also known as an impact gun, is the tool we recommend most. Why? Because it’s powerful, fast, and quite affordable. It’s best to set it at medium power for top performance.

Be sure to have the proper torque setting to avoid stripping the bolt heads, or else they will be useless for other projects. We also recommend purchasing a replacement battery, so your assembly process is not interrupted by a dead battery.

All Flexpipe joint sets are assembled with M6-N nuts and M6-25B bolts. The term M6 refers to the outer metric diameter of the head, which is 6 mm.

Now that you know all the characteristics of these assembling tools, you should be able to determine which is the right tool to assemble your Flexpipe structures. Remember that it’s essential to evaluate the scope of your project correctly, so you purchase the tool that best suits your needs.