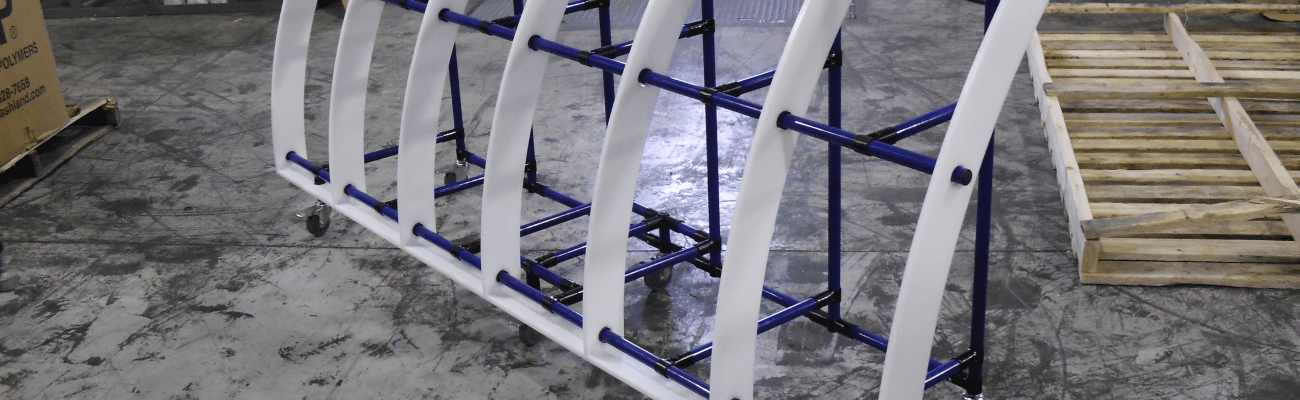

Aerospace Requires Mobile, Scalable Material Handling

The aerospace industry relies upon a worldwide interconnected supply chain where time-critical and essential raw materials, machined parts, and integrated assemblies must be delivered on time and in good working order. Lean environments abound, and suppliers on multiple continents must focus on eliminating waste and reducing lead times while guaranteeing the highest quality of finished products.