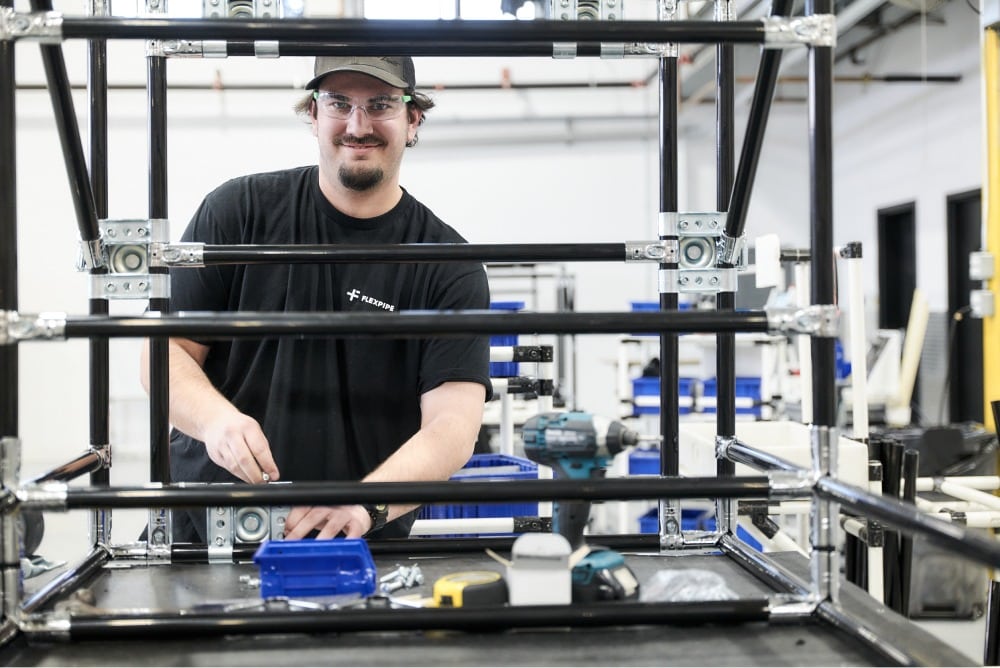

Structures Expertly Assembled by Flexpipe

At Flexpipe, building custom structures has been our business for over a decade.

We’ve made custom assembly our specialty, creating over 35,000 carts, workstations and racks designed specifically to meet your needs. Our approach goes far beyond simply supplying parts, as we assemble these components to create customized turnkey solutions.

15+

Qualified Expert Assemblers

35 000+

Custom-built Structures

14 000+

Structural Drawings Produced

What sets Flexpipe apart when it comes to custom structure fabrication?

We’re more than just a supplier of materials; we’re your trusted partner in bringing your ideas to life. Our fabrication service is distinguished by several key advantages:

- Cost savings in manufacturing

- Unrivalled speed of delivery

- Manufacturing expertise and quality

- Prototyping and continuous improvement

- Standardization and 5S methodology

- On-time delivery

- Turnkey support, including design on request

How does Flexpipe help you save money in manufacturing?

Working with Flexpipe means tangible savings. Our know-how enables us to suggest more economical alternatives and simplify your designs without compromising quality, which translates into significant savings in the long term. Mass production of five or more units reduces unit costs.

- Saving space, materials and tools

- Resource savings

- Standardization means you can reuse tried-and-tested concepts.

- Speed of execution

- Solutions to improve structural durability.

How does Flexpipe ensure that your production deadlines are met?

We understand the importance of production deadlines for our customers. When we commit to a schedule, we deliver, giving our customers peace of mind.

- Experienced and fast assemblers guarantee on-time delivery.

- Agile production team.

- Commitment to schedules.

- On-time delivery to complete your operations without delay.

- On-time delivery.

What makes Flexpipe’s quality stand out from the competition?

Our commitment to manufacturing quality is at the heart of our approach. We constantly strive to offer our customers outstanding products.

- Our team of 15 assembly technicians is dedicated to full-time assembly of tubes and joints.

- Their work is subject to strict quality controls at every stage of the process.

- We standardize our processes to guarantee high quality standards.

- Our expertise enables us to suggest improvements to enhance structural rigidity and durability.

How does Flexpipe encourage innovation with their clients?

We are firmly committed to innovation and continuous improvement. When you work with Flexpipe, you have the opportunity to test prototypes, make rapid improvements and develop products that perfectly meet your needs. We encourage the active participation of your internal teams in the Lean process by listening to their suggestions and reacting quickly to their needs. This ensures that your project is constantly evolving to achieve the highest levels of quality and efficiency.

- Prototyping: the ability to test prototypes to validate designs.

- Continuous improvement: the ability to make rapid improvements and modifications to prototypes.

- Mass production or iteration: the manufacturing team is perfectly equipped to handle high-volume orders, whether for affiliated companies or other departments within your organization.

- Involving your team: we value listening to our customers and work with your team to ensure that each solution meets your needs perfectly.

- 5S methodology: Standardization and 5S methodology to optimize processes.

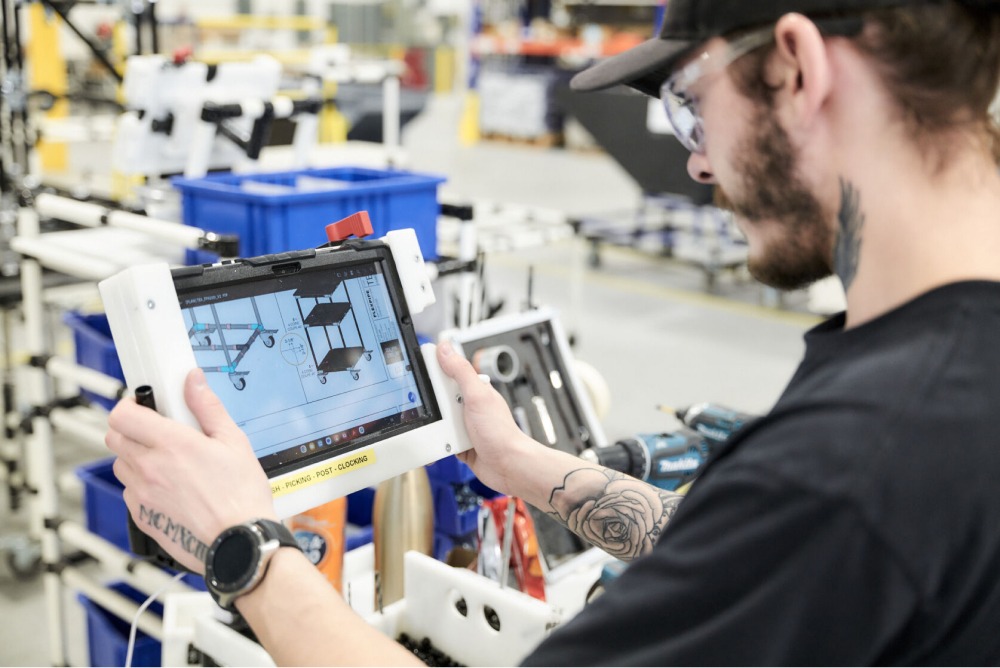

We design your projects

Our design team, Flexlab, is at the heart of our commitment to custom-built structures. Comprising a team of experienced designers, it embodies ergonomics and lean principles in every creation.

With over 10 years’ experience and more than 14,000 custom drawings to its credit, Flexlab guarantees perfect synergy between design and fabrication. This collaboration ensures an in-depth understanding of your needs, and greater responsiveness at every stage of your project. At Flexpipe, design is more than just art; it’s the driving force behind the productivity and efficiency of every structure. With Flexlab, we combine design expertise with manufacturing capability to bring your vision to life quickly and efficiently.

Discover Our Turnkey Project Journey: From Ideation to Delivery

Watch our detailed video to see every step of how Flexpipe brings your custom projects to life – from initial ideation and design to expert assembly and final delivery. Get an insider’s view of our commitment to quality and efficiency in transforming your ideas into reality.

Free plans to get you off to a good start

Explore our catalog of over 400 free plans, carefully designed by the Flexlab team, and download them now to enrich your projects. Don’t miss this opportunity to access an invaluable source of design expertise. Don’t start from scratch: build on a solid foundation with an existing plan draw by us.

Are you ready to take your manufacturing project to the next level? Contact us today to discuss your needs and find out how our expertise can turn your vision into reality.