4 SIMPLE STEPS TO GETTING STARTED WITH A MATERIAL HANDLING SYSTEM

We assisted several customers in implementing and optimizing our modular systems in their businesses. Building on this experience, we felt the need to create this 4-step guide to help you get started in using tube and joint system.

![]() Get inspired

Get inspired

![]() Make a plan

Make a plan

![]() Get prepared

Get prepared

![]() Order parts

Order parts

Get inspired

Get inspired

DECIDE ON A SIMPLE PROJECT TO BUILD FIRST

Begin your journey by selecting a straightforward structure as your initial prototype. This approach allows you to familiarize yourself with the system’s capabilities and understand its potential applications in a practical, manageable way.

Pick a project that you can showcase, yet is easy to build, such as KPI board frames, simple handling carts, or add-ons for existing workstations. Choosing a simple project will help you select the starter kit that best suits your needs.

Explore the diverse possibilities and design structures that meet your exact needs, optimizing your operations and improving overall productivity.

Flow racks

Designed for efficient handling and storage, flow rack systems ensure materials are readily available, reducing delays and improving overall process efficiency.

Racks

Modular racks organize materials, tools, and products, maximizing floor space and keeping items within reach to enhance workflow efficiency.

Workstations

Custom workstations improve ergonomics and efficiency by tailoring to specific tasks and user needs, ensuring a comfortable and productive workspace.

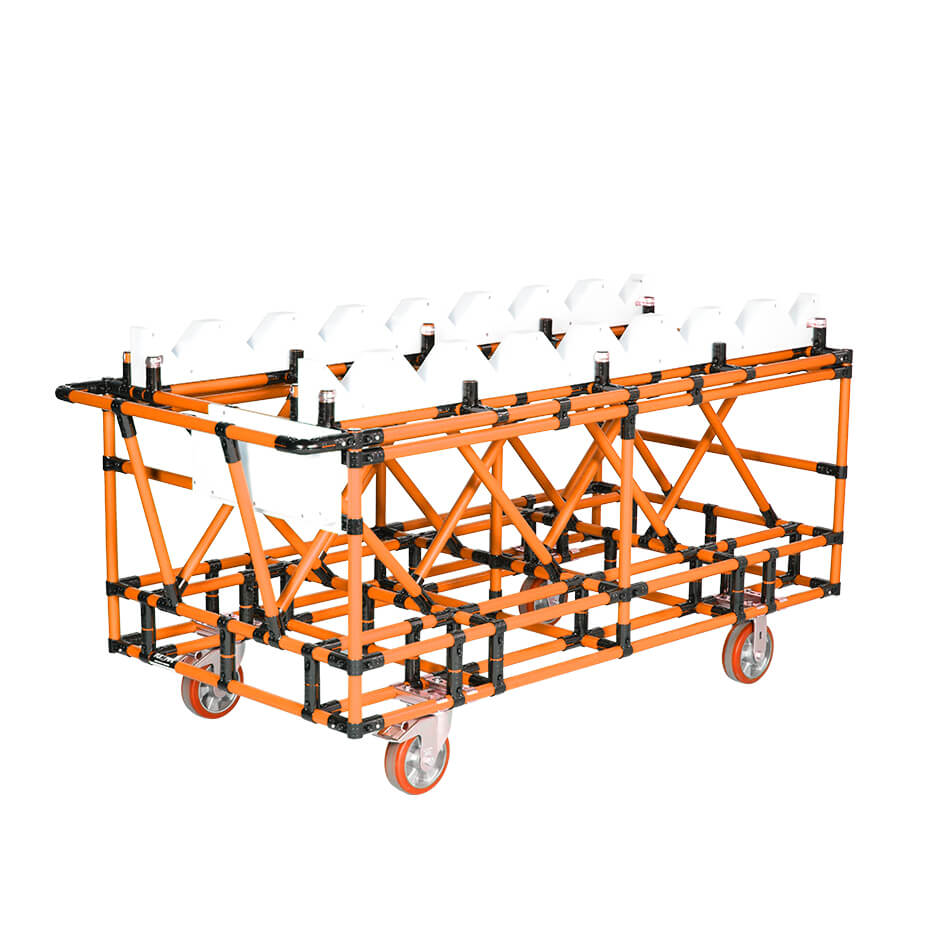

Carts

Carts are a flexible, mobile solution for transporting materials and tools across the manufacturing floor, reducing unnecessary movement and saving time to streamline operations.

Boards

Used for information display, workflow management, or tool organization, modular boards are essential in your Lean environments.

Want to optimize your factory’s handling system? Involve key employees and management!

Engaging key employees in the design process ensures their support, reducing change resistance. Involving staff in ideation fosters continuous improvement, leading to practical solutions, higher productivity, and a safer work environment.

Make a plan

Make a plan

Sketch your first Structure

By now, you likely have a direction in mind. Initial sketches don’t need to be perfect; refine them later with detailed material requirements.

Training staff to use 3D CAD software isn’t always necessary. Simple, freehand sketches can be faster and more practical, especially for less complex structures.

2-Inch cutting rule

Measure pipes according to the 2-inch rules. Adjust lengths by 2 or 4 inches based on connector orientation for accurate assembly.

Basic technical information

Consider technical aspects like loading capacity when designing structures. Visit our technical information section for detailed specifications to ensure safety and functionality.

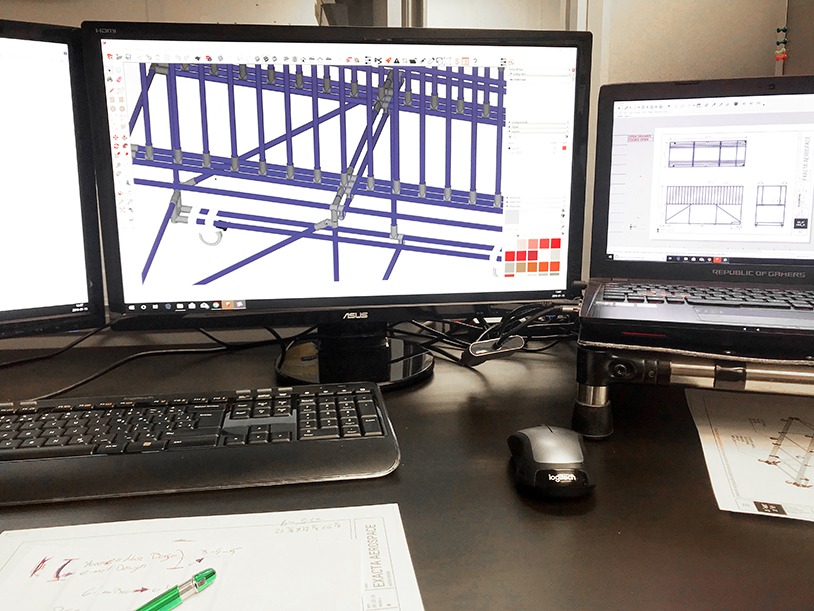

Flexpipe Creator for SketchUp

Our SketchUp extension converts wireframes into realistic models, aiding in measurements, parts and color selection. Plus it can generate cut lists for precise assembly.

List of Materials & pipes length

List all components, including pipes, joints, and accessories. Also, prepare a detailed cut list to ensure accurate material planning and reduce waste.

Need some inspirations?

Explore our comprehensive library of top plans, meticulously designed by our expert designers over the years. Browse by industry or application and download detailed plans in PDF or SketchUp formats.

Get prepared

Get prepared

MAKE SURE YOU HAVE THE PROPER TOOLS AND SPACE

Assembling a Flexpipe structure can be an easy process and can be made even quicker if you use the appropriate tools.

If you already know that you will be assembling Flexpipe on a regular basis, you should address this right away. A good setup with dedicated space, storage, and the right tools will save you up to 30% of assembly time.

Needed Tools for Assembly

All Flexpipe joint sets are assembled with the same nuts and bolts. As such, you’ll just need a 5-mm hex head tool to carry out your project.

Best Cutting Tools

Recommended tools for cutting Flexpipe: Sawzall, tube cutter, portable bandsaw, metal cutting bandsaw, cold cut saw, and portable power tubing cutter.

Optimal Workspace for Assembly

A clear, well-lit, organized area with adequate space for cutting, measuring, and storing tools is essential for efficient Flexpipe assembly.

Who are the most likely people to build your structures?

The success of your project largely depends on the personality of the person assembling the structure. An engaged assembler is more likely to design optimal structures for your project and improve them over time.

Order parts

Order parts

Order the parts you really need

Unless you have a proper bill of material on an Excel sheet, you might want to start by ordering one of our starter kits.

A starter kit is a curated collection of components designed to help you begin building modular structures. These kits typically include a selection of pipes, joints, and accessories, providing the essential elements needed to create various configurations and designs.

Need help ordering your parts? We can provide expert advice tailored to your specific needs and help you choose the most suitable starter kit based on your project’s scope, budget, and objectives.

Starter kits are ideal for those new to Flexpipe system

Flexpipe’s starter kits are going to make your job a whole lot easier. We know time is money; let us help you save on both.

Do you need a general or a specialized starter kit?

A general starter kit is versatile and suitable for a wide range of applications, making it a great choice for those starting out or needing a variety of components. On the other hand, a specialized starter kit is tailored to specific applications or industries.

They contains all the tubes, connectors, wheels, and accessories needed to build flexible structures according to your needs.

Now, you are ready to get started!

Time to build your first structure.

Need help building your first structure?

We offer various options to support you and your team.

VISIT OUR KNOWLEDGE BASE

This resource provides answers to the frequently asked questions, offering insights and guidance on a wide range of topics related to using the Flexpipe modular systems.

Explore our knowledge base

WATCH OUR VIDEOS

See our product in action, and follow step-by-step instructions. We have multiple videos online with step by step instructions to make your Flexpipe journey easier.

Visit our YourTube Channel

BECOME AN EXPERT

Flexpipe offers training options both at your facility and at Flexpipe locations. This flexibility allows you to choose the most convenient setting for your team’s training.

Discover training options