Post

5S GUIDE - A LEAN MANUFACTURING TOOL

Post

KAIZEN EVENT: EVERYTHING YOU NEED TO KNOW TO GET STARTED

Post

POKA-YOKE: A TIME-TESTED AND SIMPLE WAY TO MISTAKE-PROOF MANUFACTURINGUnlock workspace efficiency with Flexpipe’s Kaizen Foam. Dive into the world of 5S methodology and discover how to optimize tool organization, reduce waste, and elevate productivity.

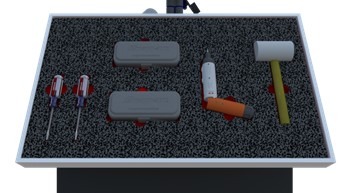

Kaizen foam is a material that allows companies to organize and efficiently store tools, parts, and consumables. Kaizen foam inserts are used in tool cabinets, tool chests, material handling carts, work benches, and flow racks. They enforce the 5S methodology by ensuring that all tools and consumables have their place and are easily found.

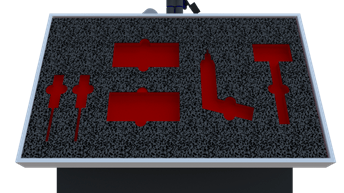

Kaizen foam is a laminated expanded polyethylene (EPE) and is one of the many Kaizen solutions offered by Flexpipe. Flexpipe’s Kaizen foam is a highly buoyant material with superior shock absorption qualities. It contains 13 black and red sandwiched foam layers that can easily be cut to fit various tools.

The foam fits securely inside the tool cabinet drawer, can be stationary on mobile carts, and can be easily positioned on an angle within flow racks. This allows technicians, employees, and line-side operators easy and immediate access to tools and consumables.

Kaizen foam addresses several of the previously covered eight (8) waste areas while allowing for the full adoption of 5S principles.

Kaizen foam inserts are the all-important material for efficient tool storage. These inserts are easily molded to fit any cabinet, tray, or shelf space. The material is easily cut, and parts and tools fit snugly and tightly.

During the Sort phase, you want to make sure you’re identifying the tools and consumables that are critical to performing a given work task or operation. Remove any non-value-added tools and items. Next, decide whether these tools should be grouped together or individually placed.

During the Sort phase, the goal is to ensure that the parts and tools that are retained and stored are aligned with the type of work operation or task being performed.

Flexpipe Kaizen foam solutions are easy to cut. Before cutting, properly trace the tool or part you want to be held by the Kaizen foam. Press the tool firmly against the foam with one hand and then trace out the region with the Flexpipe permanent and water-proof long-nose silver marker in the other hand. This marker has a 3mm bold round tip and a one and ⅞ long nose reach.

The silver ink makes a clear and bold outline against the black foam. Make sure to allow the ink to dry before cutting. Flexpipe offers several utility knives and blades that simplify cutting the Kaizen foam. Never rush your cutting. Take your time.

During the second phase, “Set in Order,” you want to ensure everything is properly labeled and identified. In the case of the Kaizen foam, this labeling and identification occurs by visual cue. The outline of the part with the marker and the eventual cutting of the foam ensures that only that specific tool will fit. It also helps to print out labels identifying the type of tool to be placed within the slotted foam.

This second step aims to ensure that employees and technicians easily reach tools and that no unnecessary or repetitive movements need to occur. There should be a natural flow to how you’re storing tools with Kaizen foam. Focus on the commonality of the parts you want stored together.

The third phase of 5S is defined by the repetitiveness with which employees and technicians keep their workplace clean. Placement of tools within the Kaizen foam should be easy. There should be plenty of space between tool locations. This third step is easily accomplished with the Kaizen foam as the tools are presented clean and organized.

This fourth phase is where you standardize tool organization with Kaizen Foam. The goal is to ensure that all tools in all workstations are correctly placed within the Kaizen foam so that no tools are lost or misplaced.

Once you’ve completely standardized the usage of the foam, you’ll next need to ensure that employees and technicians know always to put these tools away. It’s about building repetitive habits and ensuring all tools are properly placed at the end of a shift or workday.

An argument can easily be made that the last step of 5S is its most important. Don’t make the all-too-common mistake of implementing 5S once and thinking it’s enough. It isn’t. 5S and Kaizen are never-ending. There is no beginning and end.

It’s common to hear North American companies state that they have a Kaizen event every month, quarter, or year. Unfortunately, that’s missing the point entirely. Kaizen and 5S are mindsets that must be adopted and reinforced every second, minute, hour, and day of the week, month, and year.

This last stage is about sustaining 5S methodologies and continuous improvements daily. This includes immediately identifying parts and tools not stored correctly in the Kaizen foam. Reinforcing 5S practices daily ensures that all employees remember how to keep their workplace clean and store tools and consumables properly.

Kaizen foam insert allows for efficient tool storage in various manufacturing and shop floor applications. The foam can be used within tool cabinets, hold parts stationary on carts and trolleys and as a placeholder for critical components in flow racks. The material can also be used alongside shadow boards anywhere in, around, or immediately outside lean work cells.

The ideal Kaizen foam should be multi-layered laminated expanded polyethylene (EPE). It should allow for easy marking and cutting and be firm enough to withstand direct impacts and shocks. The material should be pliant enough to be tailored to any tray, cabinet drawer, or rack.

A simple tool to help flatten out the bottom of your cutouts is Flexpipe’s foam scraper. This simple tool provides an excellent, flush base free of foam cuts and residue. For those hard-to-reach places, the Flexpipe Inc.’s spinner quickly joins to any impact gun, allowing you to flatten areas with smaller envelopes.

Join Esteban in this educational video as he walks you through the process of constructing a shadow board using foam. Esteban will introduce foundational concepts of organization, lean principles, and provide insights into foam shadow board benefits and applications. This tutorial aims to impart a thorough understanding of building and adapting shadow boards. Learn from Esteban’s expertise and enhance your workspace efficiency.

Ultimately, maintaining 5S is about embracing a continuous improvement mindset. Manufacturers that make 5S work typically have weekly, monthly, and quarterly 5S audits to ensure all aspects of 5S are followed by employees and technicians. These companies regularly remind employees to respect the 5S principles, and it’s not uncommon for those reminders to happen daily until the employee or technician develops the appropriate 5S habits.

Flexpipe is regarded as a critical material handling partner to manufacturers adopting Kaizen, 5S, and other lean manufacturing and continuous improvement methodologies. As a Montreal-based innovator, designer, and supplier of tube and joint systems for modular and scalable material handling, Flexpipe. helps manufacturers reduce costs, eliminate waste, and maximize their square footage on their production floors.

Flexpipe, a Montreal-based innovator and a key subsidiary of 80/20 – a leading group in modular systems framing solutions – is highly esteemed as an indispensable partner in material handling for manufacturers. Embracing principles from Kaizen, 5S, and other lean manufacturing and continuous improvement methodologies, Flexpipe crafts, designs, and supplies cutting-edge tube and joint systems. These modular and scalable solutions empower to optimize production floor space, curtail costs, and decisively eliminate waste.

To get additional information about the products available to help with your Kaizen foam and 5S, discover our Kaizen foam tools kit.

To learn about how Flexpipe’s tube and joint systems have helped manufacturers adopt lean principles, please go to our case studies page.