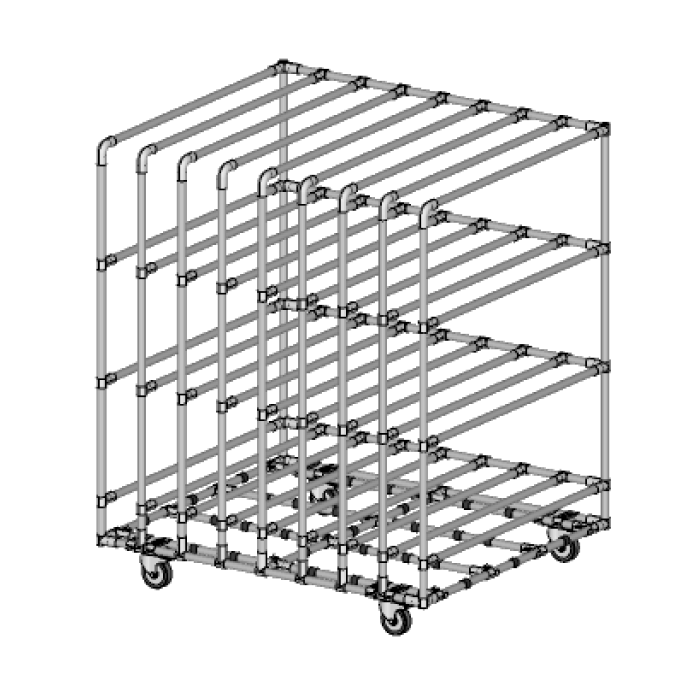

Structure

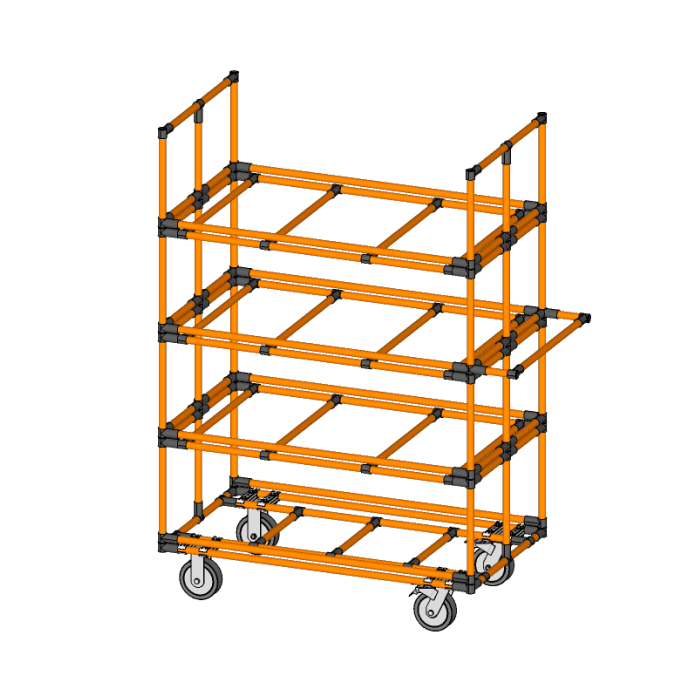

RACKS

How to build

HOW TO BUILD MODULAR CARTS

Structure

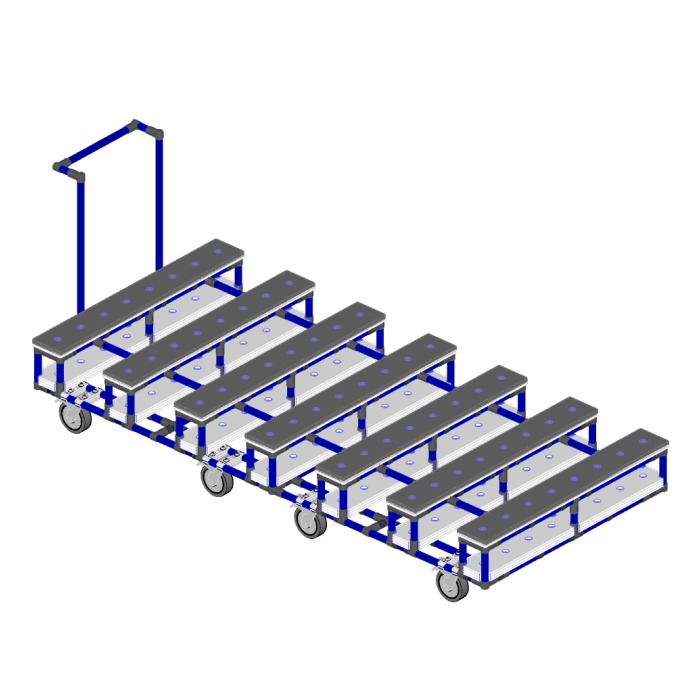

FLOW RACKS

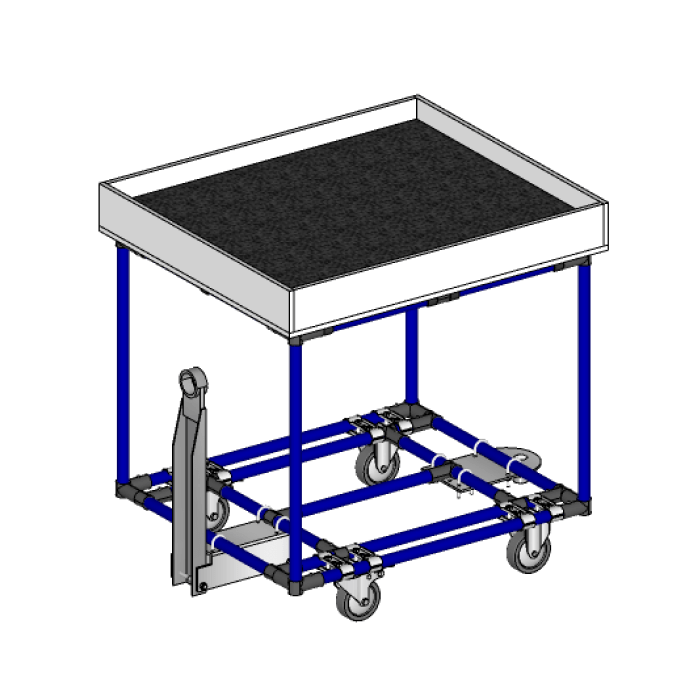

Flexpipe’s custom industrial carts are modular, scalable material handling solutions critical for ensuring efficient workspace organization. Used heavily in manufacturing environments, Flexpipe’s customizable handling carts are made from high-strength, cold-rolled steel tubes with scratch-resistant polyethylene (PE) coating. These steel tubes are used with industrial-strength roller tracks, joints, casters, fasteners, kaizen foam, and other accessories to create modular cart systems.

Learn how Flexpipe’s lean manufacturing carts help companies improve workflow, save money, and maximize the square footage of production shop floors.

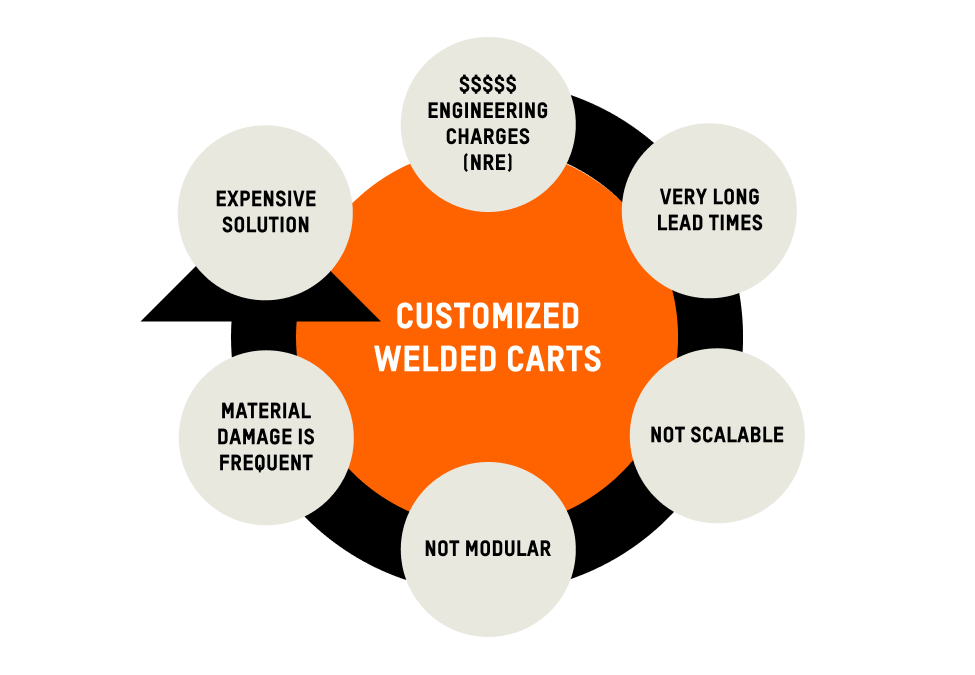

Manufacturers are often limited when looking to buy custom industrial carts. An overwhelming majority of cart suppliers weld their carts and design these material carts for general, all-purpose use. Welded carts are not designed to hold, retain, secure, or store specific bin sizes, parts, or material lengths.

Parts, consumables, bins, and tools are often strewn about the cart, able to move freely. Often, these carts are overloaded. With something securing parts and materials in place, damage to parts and materials occurs frequently. Requesting a customized welded cart is far too expensive, involves non-recurring engineering (NRE) design charges, and always includes an extended lead time.

Flexpipe carts are on-site material transport carts that can be adjusted, modified, or changed at any time. These changes can often be completed within minutes instead of weeks and even months with welded material handling structures. This is the power of using modular, scalable material handling solutions.

There is no limitation to the type of customizable handling carts that can be designed and assembled with the Flexpipe solution. Flexpipe is the ultimate DIY cart construction tool, allowing you to create customized manufacturing carts in almost any configuration. The only limitation is your imagination.

Companies can assemble kitting carts, tug carts/tow carts/tuggable carts, work-in-progress (WIP) carts, warehouse picking carts, and truck carts.

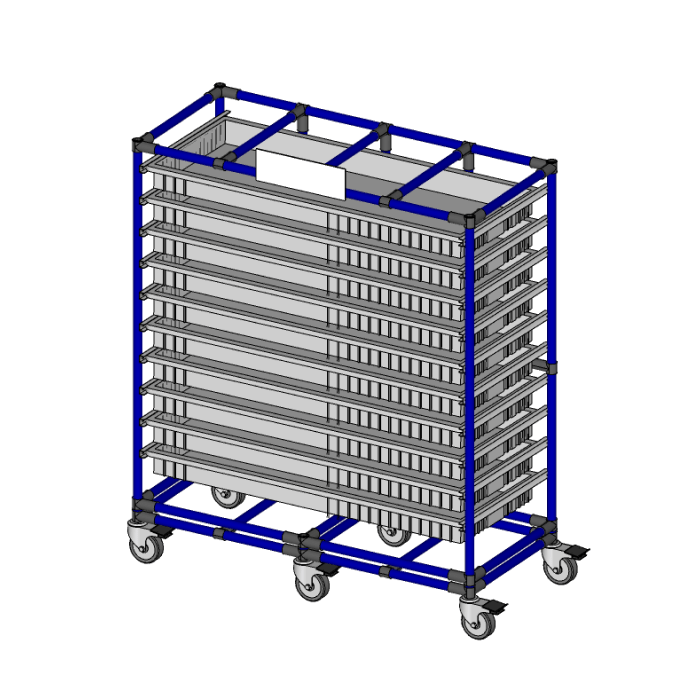

A kitting area is where various inventory items are assembled into kits and placed in mobile bins on kitting carts, which are then transported to the usage point. In lean manufacturing, these areas are typically close to work cells and workstations, often near warehouses or storage areas.

The kitting process begins when a customer orders a product. Each product has a Bill of Materials (BOM), detailing all necessary materials and parts. Kitting helps reduce warehouse costs, streamline packing and shipping, and improves inventory tracking.

Flexpipe kitting carts are essential for lean production lines. They can be customized with specific slots for components and bins, serving as a Poka Yoke (error-proofing) tool by ensuring only the correct parts are used. This saves time and streamlines workflow, as production staff receive the right parts without unnecessary searching or unpacking.

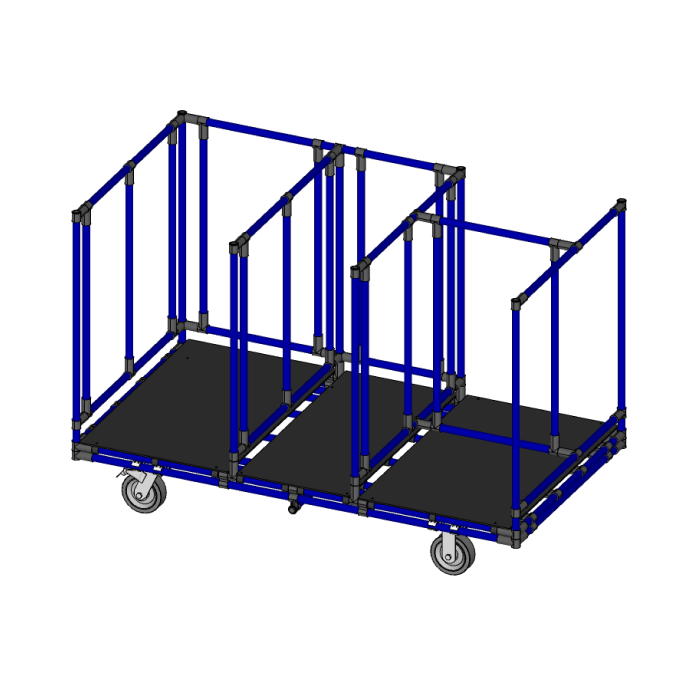

Manufacturers are often required to transport large, heavy volumes of parts, materials, and consumables over long distances within their manufacturing plants. A tug cart or tow cart – sometimes called a “tuggable” cart – is a heavy industrial cart with a robust and sturdy base that transports heavy volumes of materials and parts.

Multiple tugger carts joined to one another are referred to as a tugger train, which is pulled or pushed by a battery-powered tugger train. These tugger trains allow manufacturers to simplify workflow by making a single trip instead of multiple, longer, more time-consuming trips with a single-transport forklift or multiple smaller carts, which increases traffic. Instead, traffic is lowered with a tugger train.

Flexpipe tuggable carts are modular cart systems assembled with galvanized square steel tubes that are 1-inch and 9/16. This high-strength steel tube is used for the base of all tugger carts. Once again, a Flexpipe tugger cart can be customized to fit particular parts, bins, cartons, and box sizes.

Ultimately, a Flexpipe tugger cart allows you to replenish line-side flow racks requiring production components, allowing operators and technicians to gather more parts and materials in a single pass than with multiple smaller carts.

WIP (Work in Progress) carts are the perfect solution to move semi-finished goods from one workstation to another or to move the products from a workstation to a WIP rack located in a holding area. Again, with Flexpipe material handling solutions, customization and flexibility are key. You can customize WIP carts to hold products at different stages of their assembly.

WIP carts reduce human errors and mistakes as employees receive semi-finished goods specifically assembled for the next work task. WIP Flexpipe carts reduce overstock, mitigate errors, and eliminate tripping hazards or potential accidents by saving floor space.

Most warehouse and inventory employees use general, all-purpose welded carts mainly because companies are unaware of modular tube and joint systems like Flexpipe. They use these welded carts for a time and may try to modify them to accommodate different needs. This rarely, if ever, works.

Flexpipe warehouse picking carts are customized mobile warehouse carts that simplify how your warehouse, stocking, and inventory personnel stock, retrieve, and move parts, boxes, materials, and consumables. These Flexpipe customizable handling carts can be configured to any dimension to accommodate any inventory skew, giving your people the ultimate flexibility.

The most impressive part of a Flexpipe warehouse picking cart is that you customize its size, width, and dimensions to your existing inventory racking rather than adjusting the racking to a fixed welded cart. Companies often purchase welded carts only to find they’re too wide for their current inventory racking. These welded carts make storing and retrieving inventory time-consuming and sometimes dangerous.

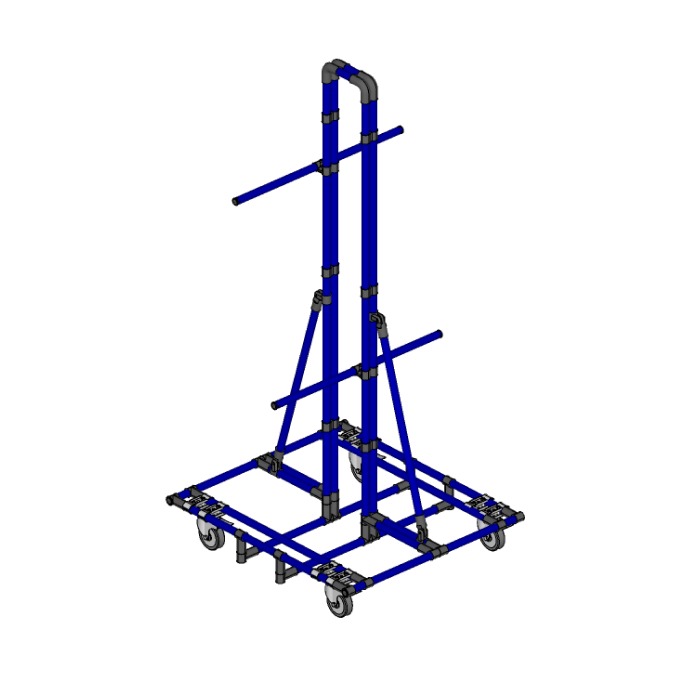

Simply put, a Flexpipe truck cart is a customized cart that safely and securely holds finished products of different sizes and configurations for transport to a customer’s facility. A Flexpipe truck cart protects the finished product during transport and ensures the part arrives at the customer’s warehouse or production shop floor in good working order.

A Flexpipe truck cart can be loaded onto a truck, delivered to the customer’s facility, and immediately positioned in front or beside a lean work cell or workstation. This saves valuable handling times for operators and technicians as the customer doesn’t need to allocate personnel to load and unload. The cart is there for the operator to remove parts as needed.

While the current truck cart is at the customer’s facility, a replacement truck cart can be scheduled to arrive when the first truck cart’s parts have been used. This further saves your customer’s time.

Transport cart

Download this plan

SCRAP CART

Download this plan

CARDBOARD CART

Download this plan

KITTING CART

Download this plan

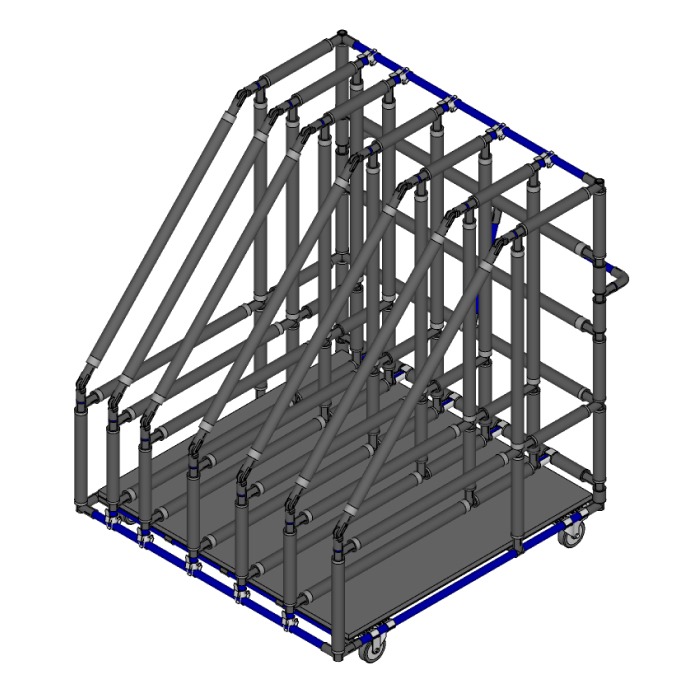

PLANE PART CART

Download this plan

PACKAGING CART

Download this plan

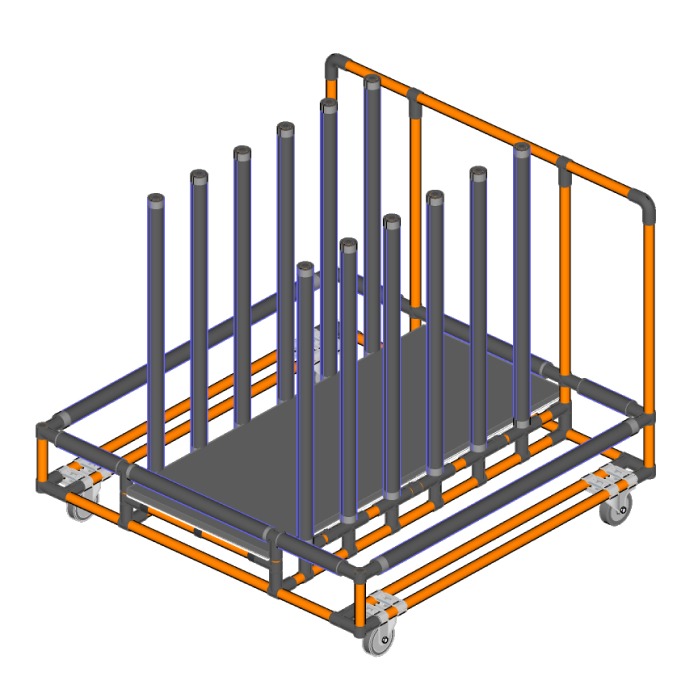

BIN CART

Download this plan

INSPECTION CART

Download this plan

HEADLAMP CART

Download this plan

pallet transport cart

Download this plan

Compartiments cart

Download this plan

SIDEWALL CART

Download this plan

There are several reasons to customize your carts. First, it allows you to create carts that securely and safely hold raw materials, semi-finished goods and consumables, and tools without contacting one another. Second, Flexpipe custom industrial carts can be modified, changed, or adjusted in a fraction of the time compared to other welded or wood cart structures. Third, a welded cart can cost anywhere from $700 to $900, while a comparative Flexpipe cart costs about $250 to $300.

Customizing your carts allows your material handling solutions to scale with the growth of your manufacturing. Business is never static or stationary. Product designs change, and with that change comes the need to handle, store, and move different-sized materials, parts, and consumables. Modular, scalable, and customizable carts allow you to adjust to that change quickly.

Another reason is that Flexpipe’s custom industrial carts are critical in reducing the square footage of your production shop floor and warehouse or inventory storage spaces. Maximizing your space means eliminating hazards and obstructions that impact workflow or lead to accidents and injury. In addition, maximizing your warehouse square footage means you don’t have to rent or lease larger warehouse space, saving you money.

Finally, customizing your carts allows you to adopt lean manufacturing best practices. Toyota Production System (TPS) philosophies like 5S and Kaizen emphasize continuous improvement to reduce costs, improve quality, and reduce delivery times. These methodologies emphasize constant changes to reduce waste in all its forms.

The first, all-important rule of any Flexpipe cart is to ensure you’ve properly accounted for the loading capacity of your structure. Flexpipe used third-party independent laboratory compression testing on all lengths and thicknesses of pipe. These data points were then used to compile the Flexpipe Loading Capacity Calculator. This downloadable Excel sheet calculates the weight a single pipe can support based on its length and thickness.

There are two ways to customize a cart with Flexpipe.

1. DIY Cart Construction: Design and Assemble Yourself

The first is to use the free Flexpipe Creator Extension. This free plugin to Sketchup allows you to design your entire structure and place your order directly from the user interface — no need for manual drawings. There is no need for a cumbersome Autocad where everything involves cutting and pasting. Instead, you use the software’s AI to design your structure.

Once your design is finished, you click on an icon, which takes you to your bill of material (BOM) and part breakdown. This screen provides a complete summary of the lengths of pipes, casters, joints, roller tracks, fasteners, and other accessories needed to assemble your finished structure. The Flexpipe Creator Extension empowers companies to design their own structures in a fraction of the time compared to conventional means.

2. Flexpipe’s Fabrication and Design Team

The second method is to have Flexpipe’s fabrication team design your structure. In this case, you would provide Flexpipe with your material handling structure’s outside dimensions or skeleton. The Flexpipe fabrication team would then create your structure for you. In addition, the fabrication team could then pre-cut your pipes so that you receive everything ready to assemble, like an Ikea box – but nowhere near as complicated.

Every day, companies in multiple industries benefit from using Flexpipe carts. Most manufacturers looking to adopt lean manufacturing or continuous improvement can benefit from Flexpipe’s custom industrial carts. Furniture manufacturers use Flexpipe carts, as do manufacturers, integrators, and distributors in the aerospace, automotive, agricultural, and hydraulic industries, among others.

Companies wanting to reduce the square footage of their warehouse or shop floor can benefit from the scalability and flexibility of Flexpipe’s customizable handling carts. Manufacturers of equipment and machinery can also benefit. Ultimately, any company managing materials weighing less than 2,000 pounds can benefit from Flexpipe’s DIY cart construction.

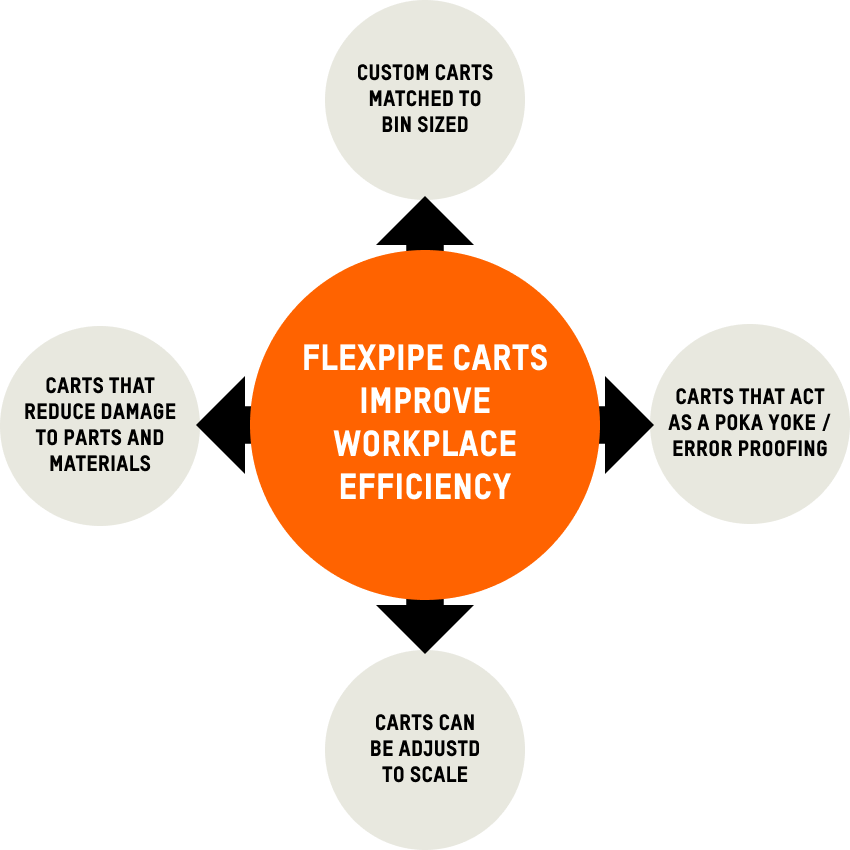

Flexpipe carts enhance workplace efficiency by simplifying workflow across the shop floor, between adjacent workstations or lean work cells, and within warehousing and inventory. The ability to create customized carts specifically tailored to your material, part, consumable, and bin sizes ensures those parts are properly secured, stored, and handled.

With Flexpipe carts, there is less incidence of obsolescence or damage to parts, materials, tools, and consumables as they are always properly secured in place on a Flexpipe cart. This reduces human errors, saves valuable time, and helps lower costs.

There are several different ways to define the return on investment (ROI) of using Flexpipe’s modular cart systems. The first is to determine how much you’ve spent on welded carts and then compare them to the average cost of a comparable Flexpipe cart.

As mentioned, the average cost of a welded cart is typically around $700 to $900 – not including delivery. A comparable Flexpipe cart would be about $250 – maybe $300. You could then take the $450 to $600 savings multiplied by the number of welded carts you purchased.

Another way is to determine how much money your company has lost from parts, consumables, materials, or tools lost or damaged due to them being piled upon a welded cart. Again, these parts would all have their own designed locations on a Flexpipe cart.

Other companies have determined their ROI with Flexpipe by calculating how much space they’ve saved and how much they’ve maximized the square footage of their shop floor or warehouse. Still, other companies have tracked how using Flexpipe carts has helped them reduce transit cycle times to move material and their overall lead times in manufacturing.

Flexpipe is an innovator, designer, assembler, and facilitator of low-cost, strong, industrial-strength material handling structures. Its innovative steel tube and joint system helps companies create their own DIY cart construction kit to assemble whatever material handling structure they need.

Flexpipe carts are the ideal lean manufacturing and continuous improvement tool, easily changed and modified at any time.

To gain insight into how Flexpipe’s solution has helped multiple companies, please go to our case studies. If you’re already convinced and want to get started, contact us now.