Technical Data

HOW TO CALCULATE THE LOADING CAPACITY FOR MODULAR STRUCTURES

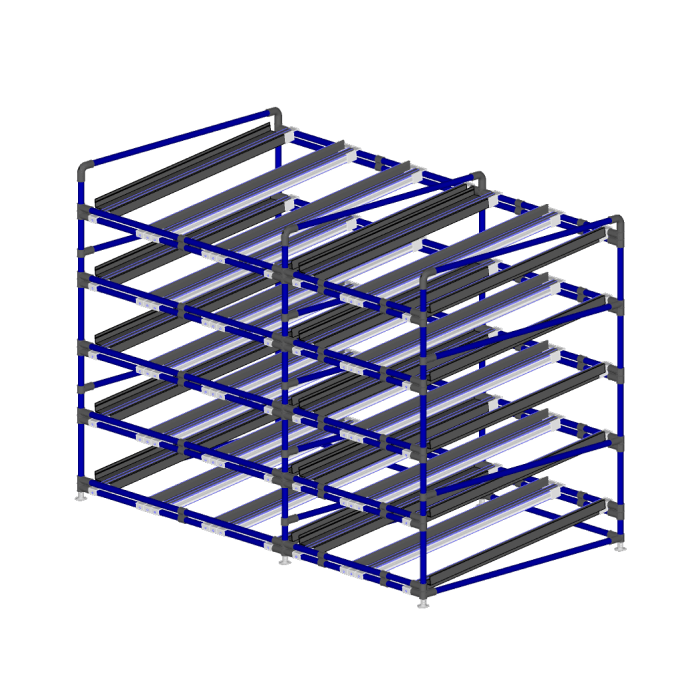

Structure

WORKSTATIONS

Structure

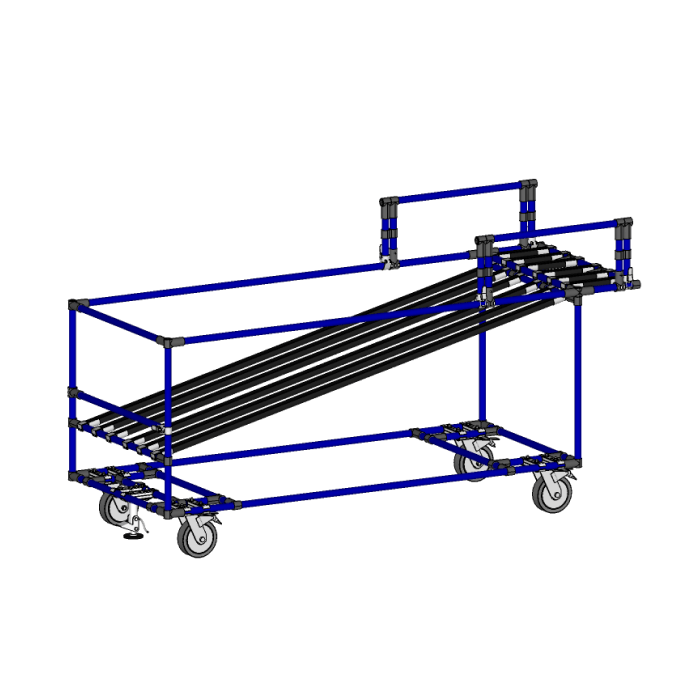

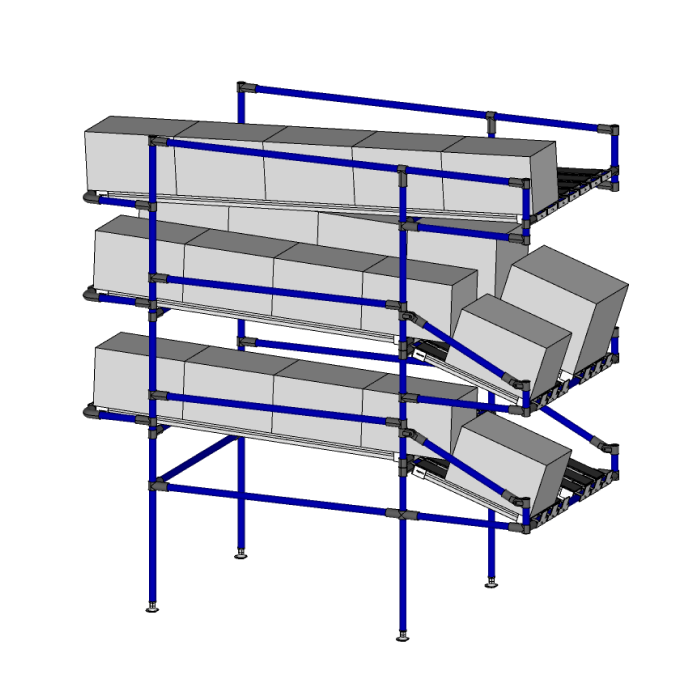

CARTSGravity flow racks can be found in warehouses, distribution centers, production shop floors, lean manufacturing environments, near assembly lines and lean work cells, as well as in packaging and shipping. These racks ease workflow, improve productivity, simplify material handling, improve materials flow, and reduce costs.

Read on to learn more about gravity flow racks.

Gravity flow racks are essential to any manufacturer’s effort toward maximizing its square footage within its warehouse, shipping, assembly, or manufacturing and production spaces. The proper flow rack system can reduce the square footage of these high-traffic areas while helping to reduce the cycle times associated with kitting, picking, manufacturing, storing, moving, assembling, and shipping finished goods.

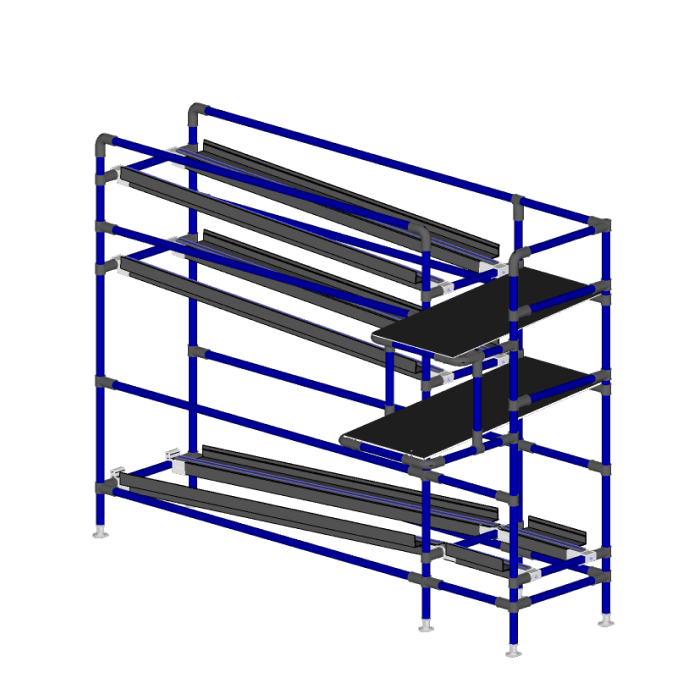

Let’s start with return lines for empty containers: these are tracks that move empty containers from the production side to the supply side where an employee can replenish necessary parts. This way, employees do not have to step into the production zone to load or unload containers.

Now, while return lines are not a type of gravity feed racks we highly recommend implementing them for these reasons: to make part replenishment faster, reduce work interruptions so the production line can maintain its pace, and free up employee workspace. For ergonomic reasons, return lines are always located at the bottom or the top of the structures.

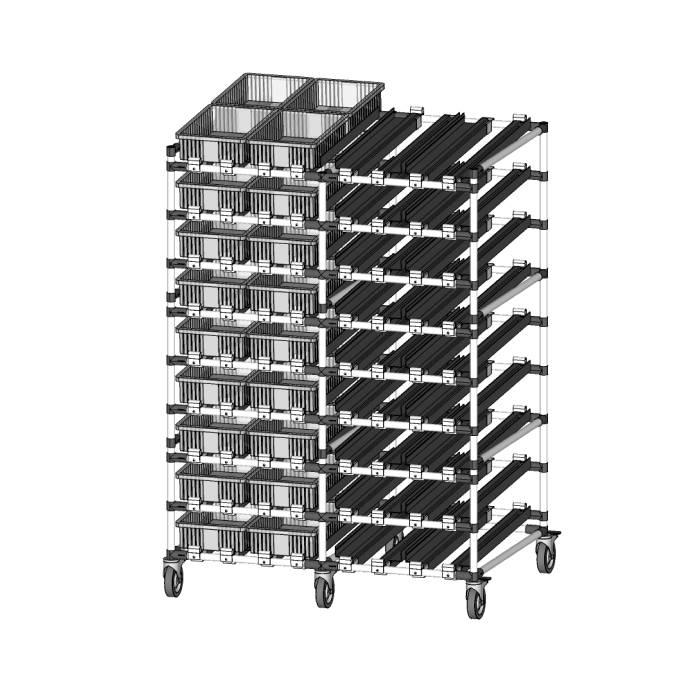

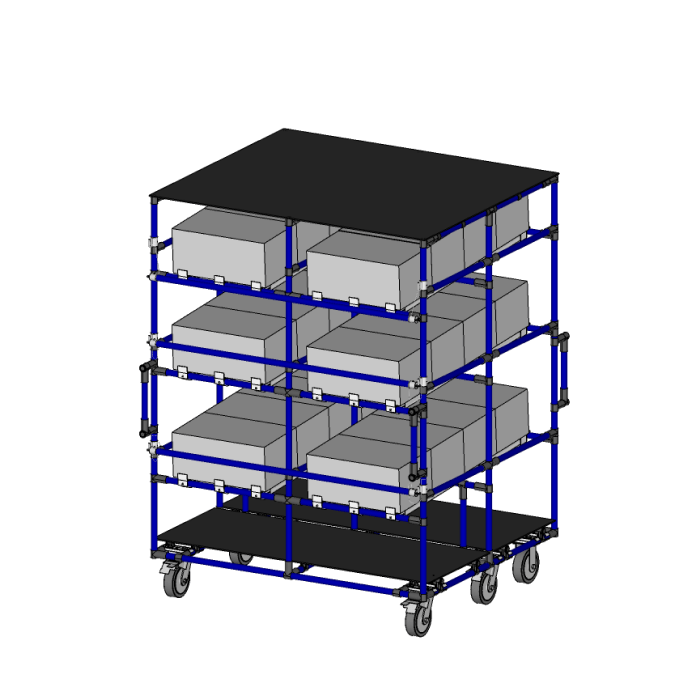

Supermarket racks, or marketplace racks, are higher density flow racks strategically located on the production floor to create mini stockrooms. Gravity flow racks in warehouse reduce transportation time—one of lean manufacturing’s eight wastes—between the production line and the storage area, in addition to cutting down on forklift traffic.

The stock level in a marketplace rack will be higher than the point-of-use racking, but lower than the central warehouse.

While most gravity flow shelvings are designed to be in a straight line, some of them are built in an L-shape. This configuration saves workers from making unnecessary, repetitive movements. L-shaped gravity racking is used widely in the automotive industry to bring parts as close as possible to the operator’s machine. However, these structures are not intended for this industry only; they can be used in any environment to make workers’ tasks safer and more efficient. Check out how to build the ultimate L-Shaped flowrack.

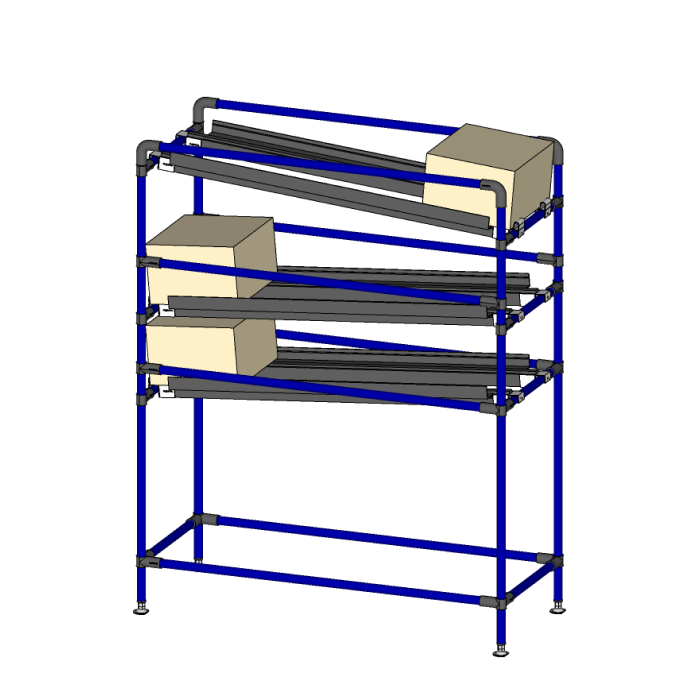

Depending on the size and weight of your containers, it is best to test and rework your prototype, so it accurately meets your requirements. Once you have mastered this type of structure, you will be able to create a Z-shaped flow rack with two angles.

These structures incorporate the concept of gravity racks by their eight-foot roller tracks. The one-piece flow concept is a core element of lean manufacturing, which is widely used in the Toyota Production System (TPS) and where each operation only builds what the next operation needs. Subway restaurants also use single-piece flows to custom-make one sandwich at a time on a long—but not deep—counter.

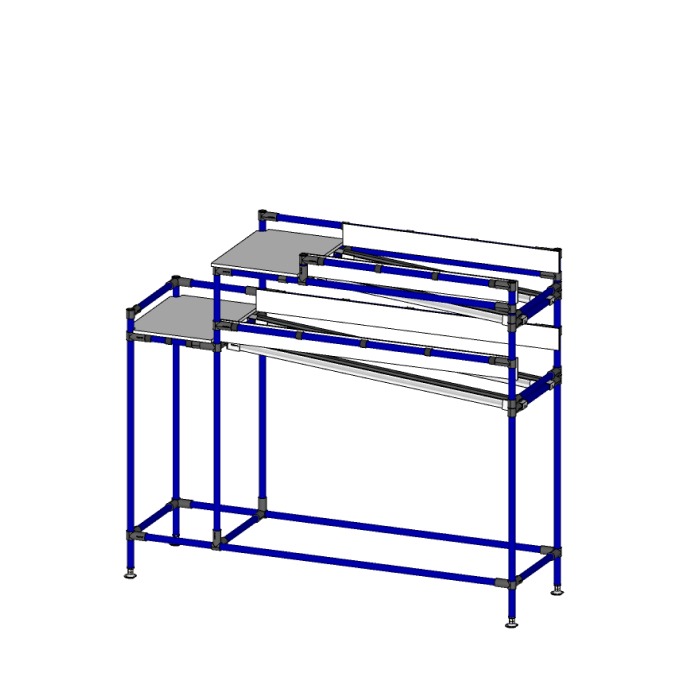

The stations are built in such a way that employees can work on only one product at a time. By creating a workspace restricted to the bare minimum, workers naturally carry out their tasks according to the one-piece flow concept. Also, as roller tracks also move products more efficiently from one location to the next, employees are less inclined to make unnecessary movements.

Disvover here how to maximize your employees day-to-day tasks

Flow tracks are integrated into lean manufacturing workstations to feed workers with parts, raw material, hardware, fasteners, or for sub-assemblies. They are used for small-density bins such as fasteners, whereas portable flow racks units will store bigger parts. Additionally, embedding gravity racks into workstations saves floor space and reduces costs. When designing return tracks for empty containers under a workstation, remember to make them short enough to leave enough room for the workers’ feet.

Flow rack supermarket

Download this plan

”L” Flowrack with return

Download this plan

Frozen milk rack

Download this plan

Flow rack 2 in 1 out

Download this plan

Gravity flowrack with pipe

Download this plan

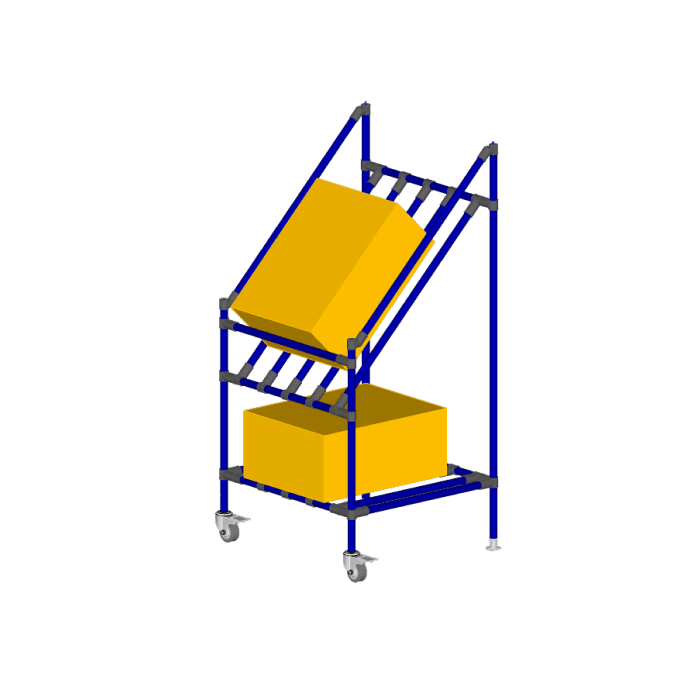

Unload cart

Download this plan

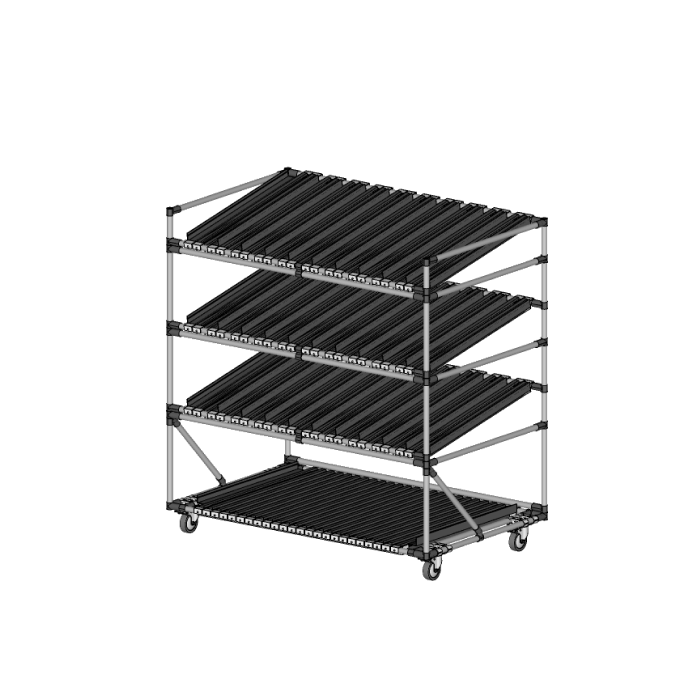

Flowrack

Download this plan

Goods GFR with removable stoppers

Download this plan

Production picking GFR

Download this plan

Kanban GFR

Download this plan

Multi level tote rack

Download this plan

Finished Goods GFR

Download this plan

A gravity flow rack is sometimes called an angle flow rack, kanban flow rack, carton flow rack, or warehouse flow rack – is a material handling system. It gets its name because it uses gravity to hold containers and boxes in place until one of the bins or boxes is removed.

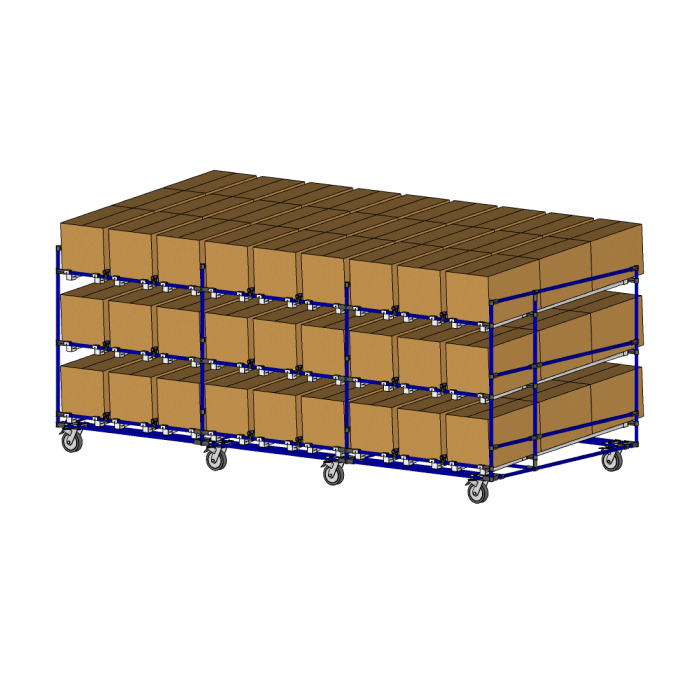

A flow rack system holds several bins, parcels, or boxes at an angular position of 3 to 4 percent. Rollers within the racks control the movement of cartons, packages, and containers. Materials, products, and consumables within these bins or boxes are held in position by the weight of the preceding boxes and a stopper or holder at the bottom of the rack.

There are multiple names companies use to describe their flow racks. Sometimes it’s called a mobile flow rack, carton flow rack, angle flow rack, warehouse flow rack, and supermarket rack. Other names include stationary flow rack, modular flow rack, tilt shelf, drive-in rack, skate wheel flow rack, and sliding rack, among many others.

Regardless of the nomenclature, a flow rack system typically falls under three main categories: pushback, pallet flow, and carton flow. Each has rails, rollers, rotating balls, or wheels that allow people to slide bins, cartons, and boxes efficiently.

OSHA is an acronym for Occupational Safety and Health Administration. The agency’s job is to ensure that workers and employees work in a safe environment where potential hazards are minimized. Companies understand that adhering to OSHA’s guidelines is the all-important step to avoiding steep fines and penalties.

Unfortunately, the OSHA guidelines and requirements concerning a material flow rack are, at best, unclear and, at worst, far too generic. The primary section within OSHA that deals with gravity flow racks is 1910.176(b), which provides some general information and guidance – albeit lacking.

“Secure storage. Storage of material shall not create a hazard. Bags, containers, bundles, etc., stored in tiers shall be stacked, blocked, interlocked, and limited in height to be stable and secure against sliding or collapse.”

On the surface, this is relatively straightforward. However, several essential points still need to be elaborated on. First, “hazards” in manufacturing and warehousing are typically defined in greater detail.

A generic term without definition or explanation – or one that is not further elaborated on – is open to interpretation by the OSHA inspector. Ultimately, it could involve being fined based simply on the viewpoint of the OSHA inspector. A good rule of thumb is ensuring that areas are clean, free of obstructions and that employees have easy access to materials.

Second, the “limited in height” statement provides no clear guidance on acceptable heights. Third, “stable and secure against sliding” is perhaps the most egregious guideline, as this is the entire purpose of a carton flow rack.

As each parcel, bin, or box is taken from the front of the flow rack, a replacement occurs by sliding down from the back. The OSHA statement of “secure against sliding” defeats the purpose of using gravity racking.

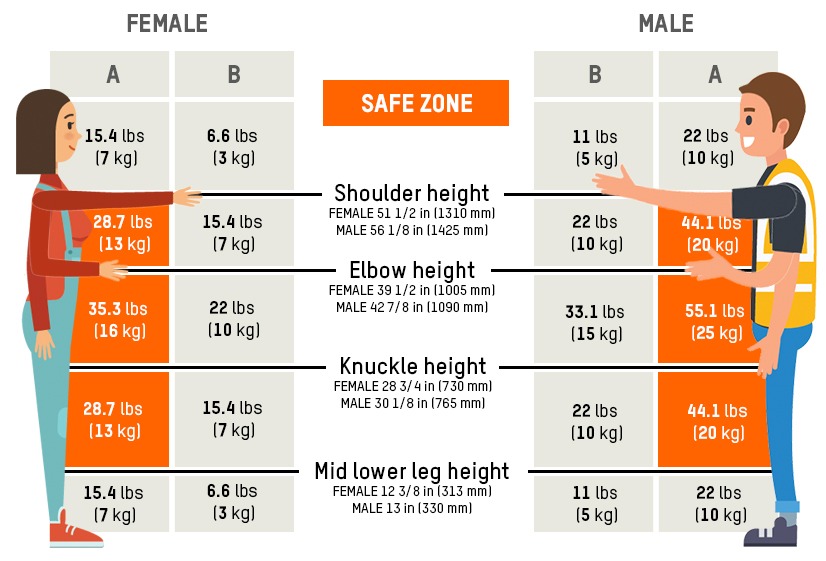

While the OSHA requirements may lack specificity, some standard ergonomic practices should be adopted with gravity flow racks. You want to ensure that you mitigate the potential for injuries so that employees are comfortable loading and unloading parcels and materials from your flow racks.

Flow racks improve employee safety and reduce absenteeism by providing a safe, ergonomic solution for material storage. Employees make minimal movements to retrieve material, consumables, and parts with a material flow rack.

If you need more than 1 level of flow, set up ergonomic landing and loading stations for your containers that range from a minimum of 24 in. up to a maximum of 60 in. The first level will store your raw materials, while the second holds empty containers.

Remember to factor in a 3-in. clearance to load and unload containers for easy picking.

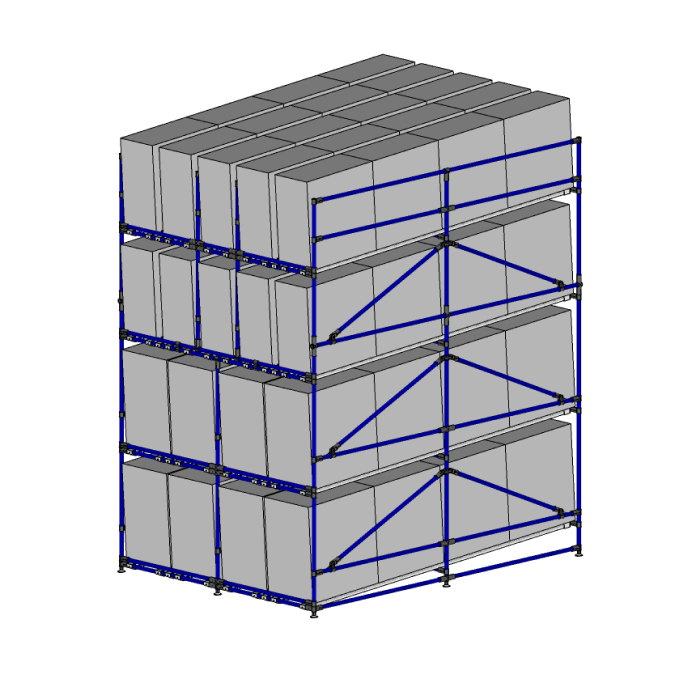

A flow through rack is an angle flow rack that can store boxes, cartons, and pallets. Flow through racking within a warehouse can hold the standard North American pallet size of 48 x 40 inches. What distinguishes flow through racks is that the boxes, cartons, or pallets are loaded from the back of the frame.

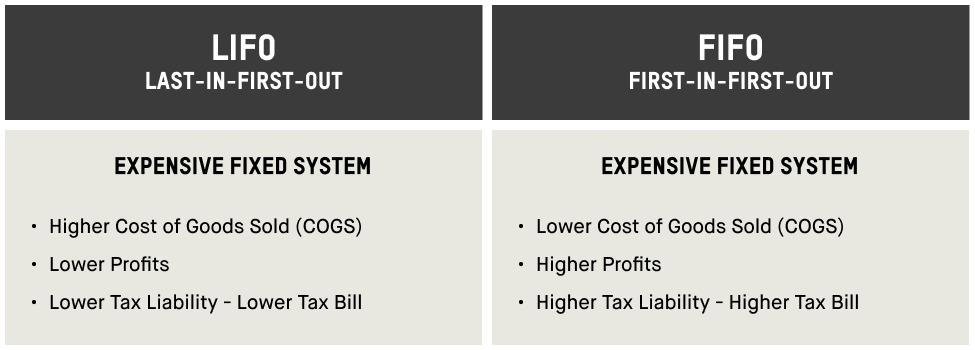

Flow-through racking is typically associated with warehouse and inventory management. This leads to discussing last-in-first-out (LIFO) and first-in-first-out (FIFO) inventory management processes.

A LIFO flow-through racking system lowers a company’s tax bill or tax liability but reduces profit on each sale. This is because the cost of goods sold (COGS) is increased the longer older inventory is held without being used or sold.

COGS increase because of the high costs of inventory carrying charges on older inventory. These carrying charges include the costs of financing, storage, damage, handling, obsolescence, and pilferage. These higher costs reduce a company’s profit on older inventory.

LIFO flow-through racking – and LIFO generally – is less frequently used than FIFO. The most obvious reason it’s used is that it helps companies save on taxes. However, there is another valid reason why a company would use a LIFO racking system, especially given today’s climate of high inflation.

During inflationary times, a LIFO flow through rack allows companies to match the rising costs of incoming shipments of materials, consumables, and parts with the price increase for their finished goods. In this way, a company can match its increasing costs with its additions to its customers.

The FIFO flow-through racking system increases a company’s tax bill or tax liability but increases profit because of lower COGS. The COGS is lower with FIFO flow-through racking because inventory carrying costs are lower. Financing is lower because inventory isn’t held as long. The costs of handling and storage are lower, as are the costs of damage, obsolescence, and pilferage.

FIFO ensures a steadily moving inventory where parts and consumables aren’t held for too long before they’re used. Shortening the amount of time inventory is held means you reduce the risk of that inventory becoming damaged or obsolete.

Gravity flow racks can be found in warehouses, distribution centers, production shop floors, lean manufacturing, production environments, near assembly lines and lean work cells, as well as in packaging and shipping. These racks ease workflow, improve productivity, simplify material handling, improve materials flow, and reduce costs.

Flow racks also improve employee safety and reduce absenteeism by providing a safe, ergonomic solution for material storage. With a material flow rack, employees make minimal movements to retrieve material, consumables, and parts.

Gravity flow racks are essential to any company’s effort toward maximizing its square footage within its warehouse, shipping, assembly, or manufacturing and production spaces. The right flow rack system can reduce the square footage of these high-traffic areas, while helping to reduce the cycle times associated with kitting, picking, manufacturing, storing, moving, assembling, and shipping finished goods.

As important as a gravity flow rack is, some critical questions must be answered regarding how, when, why, and where it’s used. In addition, it’s important to understand what companies must do to ensure their flow racking adheres to state and federal worker safety regulations.

Again, FIFO is more commonly used by today’s companies. The reason is obvious; lower inventory costs mean higher profit generated per sale. FIFO flow-through racking aligns well with some of the most progressive inventory management practices adopted by today’s cost-conscious businesses.

Companies are always searching for ways to reduce costs and increase profits. Continuous improvement methodologies like lean manufacturing focus on strategies that minimize waste. One of those wastes is having an excess amount of inventory.

By ensuring a fast-moving inventory, companies can better control – and even lower – their raw materials, parts, and consumables costs. Today’s enterprises use lean concepts to minimize inventory counts to reduce the costs of inventory, storage, and handling.

While the tax liability is higher with FIFO, the other benefits align more with today’s global business needs.

A complete flowrack system includes the material to make the frame, rollers or a roller track, wheels, brakes, ramp stops, and side rails or centralizers to ensure the box, bin, pallet, or container is correctly aligned to the center of the rack. Ideally, the rack has been designed and made to accommodate a specific size of container or box.

The roller tracks allow for easy movement of the container or box. The slight incline of 3 to 4 percent is just enough for the containers, pallets, or boxes to slide downwards once one is removed. However, the pallets would continue to fall without a ramp stop at the bottom of the flow rack.

A ramp stop must be secure and rigid enough to stop the pallets from sliding but not so hard that they cause any damage to the containers or boxes. The ultimate benefit of these racks is that boxes, bins, pallets, and containers can be stored and held in place without people manipulating or moving them.

Today’s manufacturers are always looking for solutions that help them save time, maximize available manufacturing, production, and warehouse space, minimize wasted movements, simplify workflow, and lower cycle times.

Occupying too much floor space with larger-than-needed angle flow racks creates unnecessary hazards and slows down the natural flow of work. A poorly-designed material flow rack can lead operators and manufacturing technicians to spend far too much time retrieving time-critical parts and consumables.

These issues are only exacerbated by the sheer volume of flow racks used in shipping, receiving, kitting, manufacturing, lineside areas, quality control (QC), labeling and packaging, inventory, storage, and warehousing.

Flow racking structures are ideally suited to a Kanban system. The structures are also essential in Lean Manufacturing as production lines can operate without the stoppages that would typically occur when restocking employee workstations. Implementing gravity racks can therefore substantially increase productivity.

For more information on how to build a flow rack, please read our How to build flow racks.

A modular flow rack system allows manufacturers to adjust the size and dimensions of racks so that space is maximized at all times. This means manufacturers should choose a solution that allows them to customize the dimensions of their flow racks to ensure they don’t take up too much space. When correctly managed, manufacturers can achieve the following benefits with flow racks.

Companies in all kinds of industries rely upon Flexpipe’s tube and joint system to create modular, scalable, customized, and low-cost material handling structures and solutions. The entire Flexpipe Inc. team is committed to helping companies reduce costs and simplify how they manage and use materials.

Customers can design their structures using Flexpipe’s Creator Extension plugin or have the Flexpipe design team create a customized solution.

To learn more about our customer-centric focus, contact us now.