Post

WHAT IS THE ROLE OF THE WATERSPIDER IN A LEAN MANUFACTURING STRUCTURE

Post

POKA-YOKE: A TIME-TESTED AND SIMPLE WAY TO MISTAKE-PROOF MANUFACTURING

Case Study

MAJOR CORRUGATED BOX MANUFACTURER GETS LEAN WITH FLEXPIPE

The world of lean manufacturing owes a great deal to Sakichi Toyoda, his son Sakichi Toyoda and a highly-respected Japanese engineer named Taiichi Ohno. Together they created the Toyota Production System (TPS) and introduced several simple – but highly effective – business principles that continue to produce results and improve manufacturing efficiencies to this day.

One of these principles is 5S, a continuous improvement methodology widely recognized as a building block of lean manufacturing. 5S spearheaded the rise of just-in-time (JIT), a supply chain management and lean manufacturing process that minimizes waste while maximizing efficiencies.

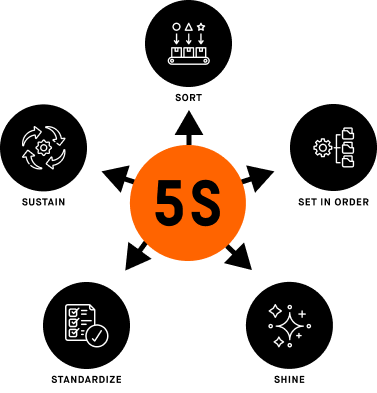

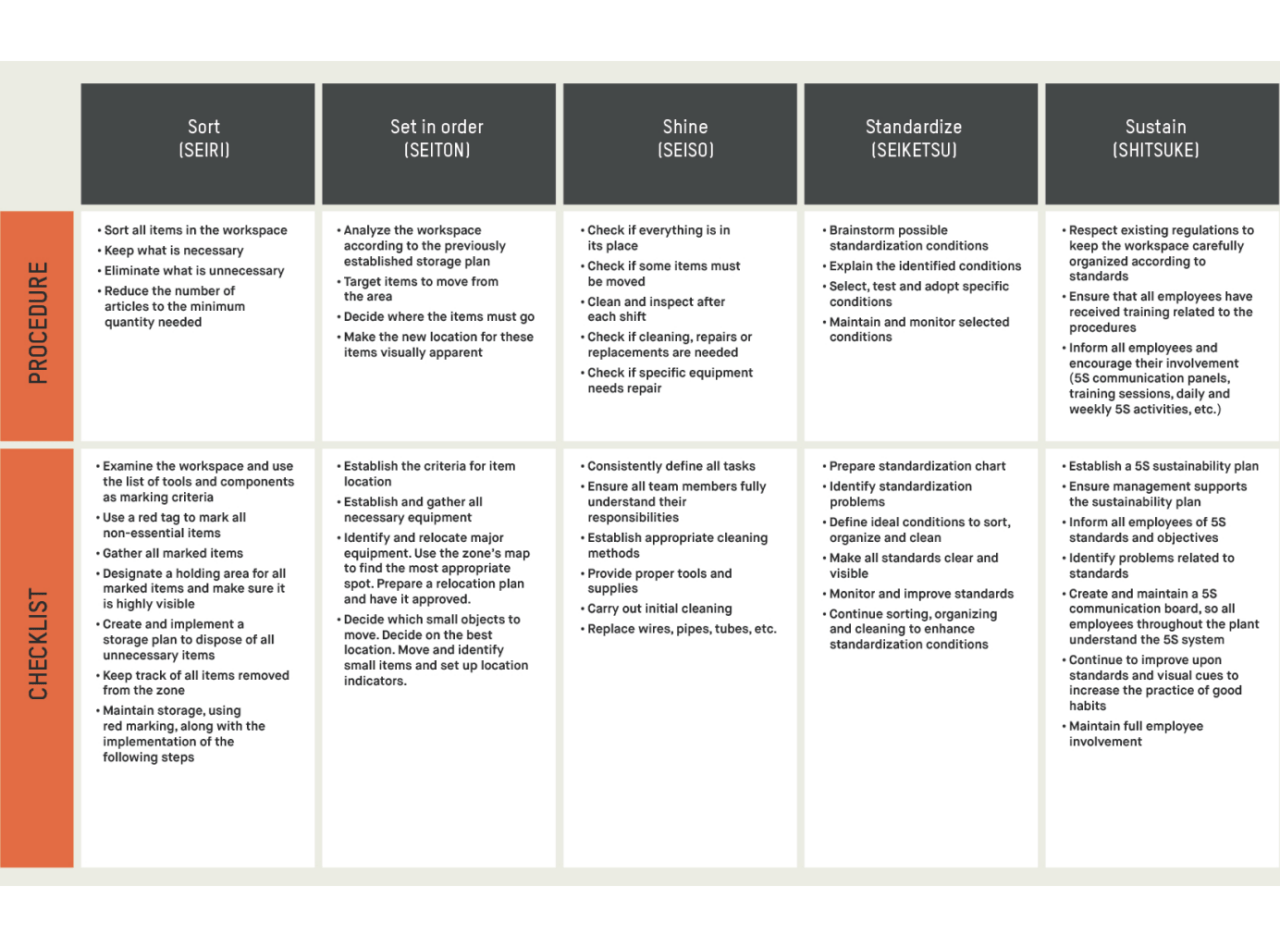

5S is an acronym for five Japanese words: seiri, seiton, seisō, seiketsu, and shitsuke. When translated, they become the pillars of a repeatable process that simplifies workplace structure, organization, and cleanliness.

In English, 5S stands for “Sort”, “Set in Order”, “Shine, “Standardize” and “Sustain”.

5S is ultimately about adopting repetitive behaviors and practices to standardize a company’s work environment. 5S is the all-important first step to ensure the repeatability of work processes; defining guidelines for workplace management, structure, organization, and cleanliness helps to eliminate time-consuming work stoppages, interruptions, waste, and delays. The result is more predictable outcomes and improved quality.

On the surface, 5S appears to be a simple set of rules that are easily implemented and followed. However, go a step further, and it becomes clear that 5S only succeeds when companies remain committed to the process.

This is not a one-time exercise. It’s not a set-it-and-forget-it solution. 5S requires a committed workforce with the discipline to follow the process daily. It must become part of a company’s culture so that the habit of following 5S steps becomes ingrained in the workforce. Here is a breakdown of 5S alongside some questions and issues to consider for each step.

Ensure that only the things needed to perform work tasks remain within the work cell.

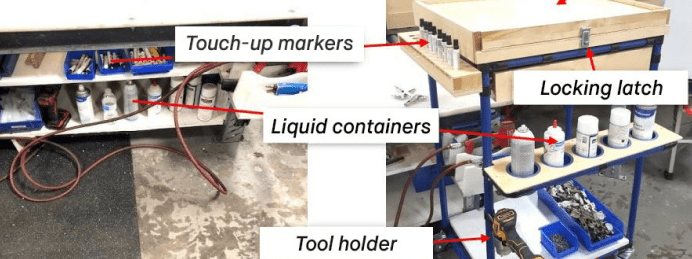

Adopt an ergonomic approach to organizing the items that remain. Ensure items are correctly identified so operators or technicians can access them safely, efficiently, and quickly. Every material, tool, work instruction, or consumable must have a designated location and be appropriately labeled and easily accessible.

Shadow boards make it easy to create outlines of parts and use placement holders so that everything fits exactly where it is supposed to.

Ensure the workspace is clean, well-maintained, organized, and free of obstructions. An end-of-day or end-of-shift cleanup is an absolute must. This can involve sweeping or mopping the floor, wiping down and cleaning tools and workbench surfaces, or ensuring that equipment and machinery are properly maintained and cleaned.

A Flexpipe crib is a perfect way to standardize a workplace. It makes the workplace more visually appealing and cuts down on wasted time looking for parts, materials and consumables.

Put an end to tribalism by creating company-wide 5S standards for workplace management. Create a daily checklist for employees and schedule workshops, so all employees and managers are aware of 5S best practices. The goal is to duplicate success so that 5S becomes routine for employees.

5S is a never-ending process. When appropriately adopted, it becomes part of a company’s culture. Periodic 5S audits and 5S meetings allow employees and management to assess progress or review non-conformance. Constant reinforcement of 5S guidelines will ensure it becomes ingrained within a workforce.

The goal of 5S within lean manufacturing environments is to bring stability and organization to work environments. In this sense, 5S is a critical building block of lean manufacturing. It simplifies workplace organization by creating simple-to-use guidelines that help to reduce the impact of waste in manufacturing.

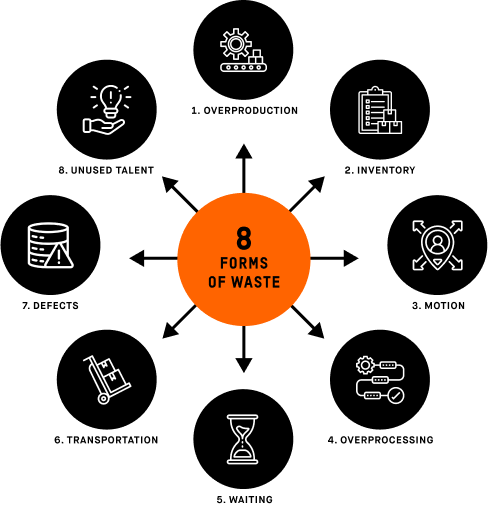

5S was a closely guarded secret by Toyota until the late ’80s and early ‘90s. The growth of Toyota – and the economic boom of the 80s – spurred global interest in Toyota’s processes. Western industries learned about the intricacies of the Toyota Production System and soon started adopting 5S practices to tackle what the Toyota Production System defined as eight forms of waste.

Companies often produce more than what’s required – or more than what they currently have demand for. These companies believe it’s best to have machines and equipment running than have them sitting idle. Unfortunately, manufacturing more than what’s needed increases production and storage costs. It can lead to production errors, interrupt workflow, and increase turn-around times (TAT).

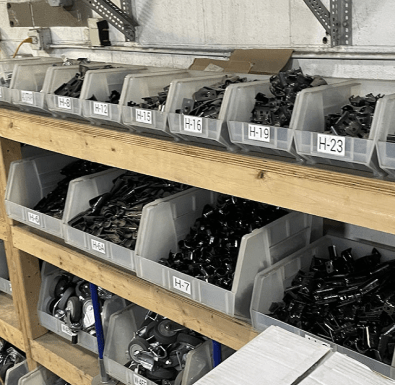

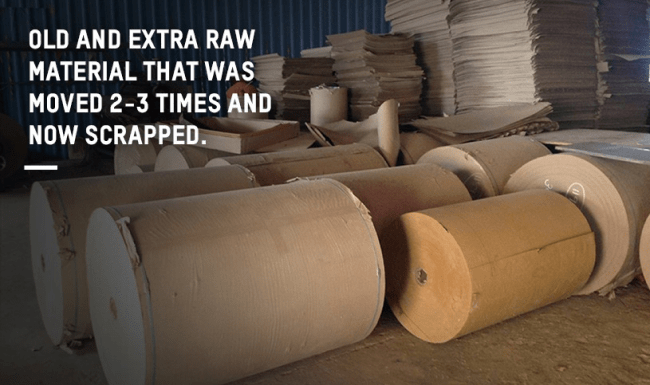

Surplus inventory increases financing costs and leads to part and material obsolescence, damage, dead stock, and higher handling and storage costs. Companies that carry too much inventory don’t benefit from economies of scale when the inventory becomes damaged due to excessive handling and storage

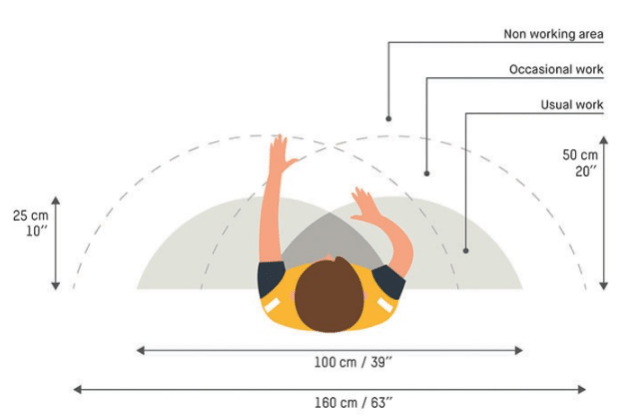

Excessive and unnecessary movements increase cycle times and reduce production throughput. This can include having employees walk long distances for parts, tools, and materials to something as simple as having them bend, lift, stretch or reach too often.

Ergonomic workstations emphasize minimal movement so that work is seamless and the operator is not overexerting themselves with unnecessary movement.

Poor work processes, bottlenecks, inefficient procedures, excessive approvals, and convoluted workflow wastes production time. Redundant and repetitive tasks add unnecessary time and increase costs while not adding value.

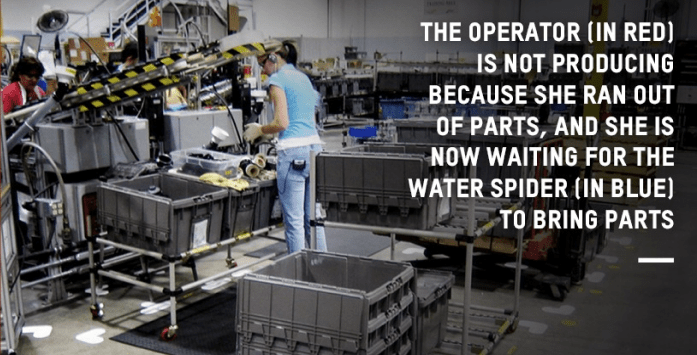

Poorly structured workflow leads to idle machinery and equipment. When work operations aren’t timed, it leads to machinery, equipment, and production employees waiting for material and semi-finished or work-in-process parts. Over time overproduction occurs, and excessive inventory is created.

Long distances between work cells increase transit times for work-in-process and semi-finished parts.

Any excessive transportation or movement of people, equipment, parts, tools, and machinery adds time and increases waste. This golf cart was optimized as a transportation waste solution.

Product defects increase costs and impact quality. Most defects must be reworked or repaired, which adds unnecessary time.

Defects can occur from repetitive work processes, bad material, poor training, inadequate tools, excessive handling or transportation, or poorly defined work instructions.

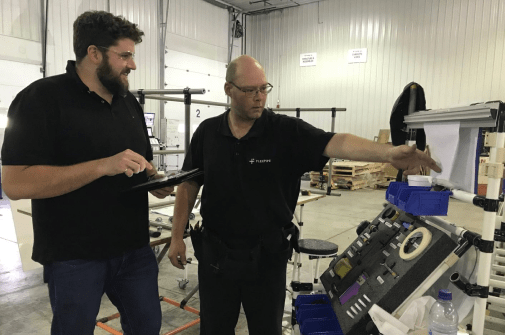

Employees working in silos rob other employees of essential knowledge and expertise. Not fully leveraging an employee’s ability, talents, and insight leads to employee complacency, indifference, and turnover.

Managers must engage employees and make them part of the continuous improvement process.

This assembler became a waterspider after realizing her talent for anticipating the needs.

One of the most impressive aspects of 5S is how little it costs to get going. There are no significant capital expenditures to justify or approve. There is no equipment or machinery to purchase and little need for outside consultants.

What is required is the willingness of your management and employees to invest the time and effort to make 5S a success. A company can get going on 5S without breaking the bank. All that’s needed is the following visual queues.

Employee safety has become increasingly important in today’s manufacturing environments. That’s why some advocate for “safety” as the sixth criterion. 6S systems focus on clearly defining safety risks while minimizing hazards and obstructions. Work cells should be designed with ergonomics in mind.

Employees should have minimal movements to perform work tasks without over-exerting themselves. The goal is to mitigate the impact or incidence of injury to avoid the high costs of employee absenteeism. Companies now see absenteeism as a detrimental cost driver. The goal is to reduce this waste by ensuring that worker safety is a priority.

Identifying waste can seem somewhat daunting. Where exactly do you start? Fortunately, 5S is a continuous improvement methodology. The goal is to work at it continuously. It’s a task without an end date. There is no timetable. It’s a continuous feedback loop where each improvement is used to learn and grow.

There are several ways to identify waste. Spaghetti diagrams map the movement of parts, people, materials, and work-in-process parts on their shop floor. These diagrams can quickly identify excessive movement and uneven workflows.

Another method includes using Value Stream Mapping (VSM). This highly effective lean manufacturing tool allows companies to define the current amount of waste in their processes, starting from their customer through production and shipping.

However, as impressive as these tools are, nothing compares to seeing work performed in real-time.

Your employees hold all the keys to process improvement. They know where the bottlenecks are.

They know what causes lost time and where the waste is. Leveraging their experience, know-how, and problem-solving expertise will help improve efficiencies and productivity.

5S is just a tool, but your employees are critical to making it work.

An innovator in modular handling systems, Flexpipe has developed a large customer base across North America. Flexpipe is not only less expensive (30% less) than its competitors, but it also offers multiple customer-centric services to help customers easily integrate pipe and joint systems into their manufacturing systems.

These services include on-site visits and assessments, custom builds, excellent after-sales support and the first-of-its-kind free Flexpipe Creator extension to support material handling system designs made of modular materials.