Post

HOW TO ESTABLISH AND SUSTAIN A CONTINUOUS IMPROVEMENT CULTURE

Case Study

HOW KAIZEN INITIATIVES IMPROVED BATCH-TO-BATCH PROCESSES AT AMERICAN WOODMARK

Post

HOW TO SELL CONTINUOUS IMPROVEMENT TO SENIOR MANAGEMENTWhen manufacturers need to improve efficiencies, reduce costs, shorten lead times, and eliminate waste, they turn to the well-established continuous improvement methodology known as Kaizen. The word is Japanese for improvement, yet this one word means so much to those who adopt its principles. So, how does Kaizen work, its methodologies, and how does this relatively simple process eliminate waste and turn losses into profits? Read on to find out.

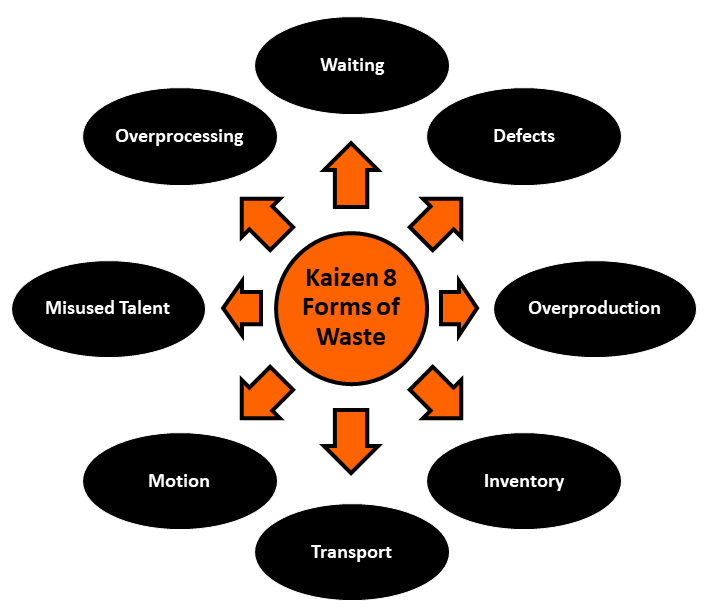

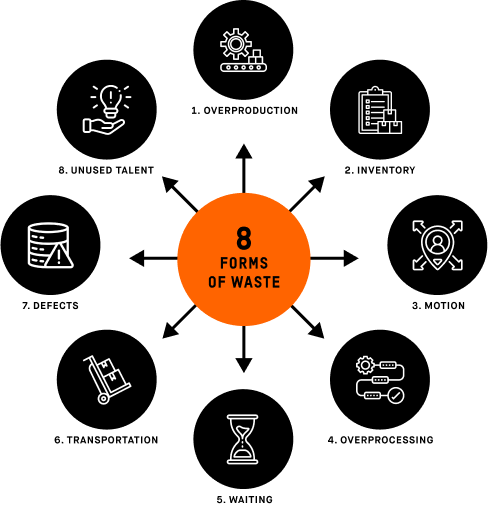

Kaizen is a mindset as much as it is a methodology. For Kaizen to truly succeed, a company’s entire workforce must be indoctrinated into its guiding principles. It is not part of a company’s culture; it is the culture. Managers, supervisors, office workers, and production employees must fully adopt Kaizen. The goal of kaizen is to eliminate every single form of waste. That waste can include overproduction, product defects, wasted movements, repetitive tasks, unnecessary approvals, redundant processes, machine downtime, excessive inventory, and idle time – to name a few.

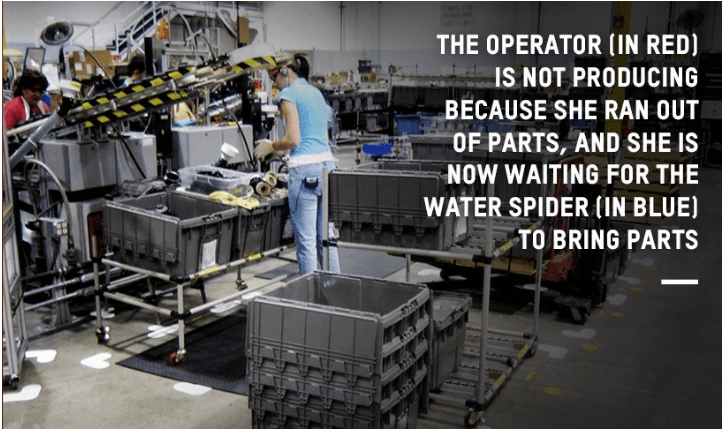

Anything that inhibits, interrupts, delays, or stalls the natural flow of work is waste, and everyone’s responsibility – from managers to supervisors to shop floor employees – is to identify and eliminate that waste. Proper training is critical. A Kaizen workforce is one where all employees are involved in the continuous improvement process. Everyone is making suggestions and offering solutions. Everyone is doing what they can to eliminate waste, and everyone has a role in improving how work is performed.

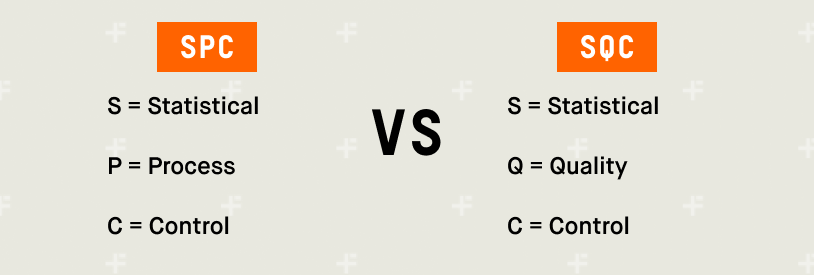

Kaizen is an amalgamation of several different business concepts. No one person can lay claim to coming up with Kaizen. Kaizen is a mixture of statistical process control (SPC), statistical quality control (SQC), procedure optimization, and repeatability.

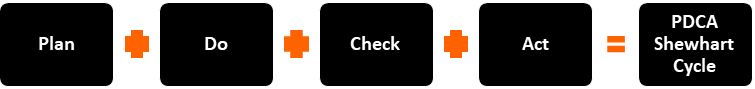

While most immediately associate Kaizen with the Toyota Production System (TPS), its origins start with Walter Shewhart, an American engineer, physicist, statistician, and businessman who worked for Bell Labs during the 1930s. Shewhart ushered in the age of statistical process control. He believed that waste could only be eliminated after a process was controlled.

The Shewhart Cycle – commonly referred to as the PDCA Cycle – is a straightforward process widely viewed as Kaizen’s ancestor. PDCA stands for Plan, Do, Check and Act. Relatively simple, right? You plan something. You then enact the plan. You check the plan’s results and then act to make the plan better. This simple cause-effect methodology earned Shewhart the moniker of the “father of statistical quality control.”

Edward Deming was an American management consultant, engineer, professor, and statistician. Deming borrowed concepts from Shewhart and expanded upon them. For a while, the two worked together. Deming saw the PDCA Cycle/Shewhart Cycle as critical to creating better quality systems. He was instrumental in these concepts being adopted by the Japanese after the second world war. Deming’s teachings were better received by Japanese companies than by American companies. The United States had built a substantial industrial complex to support the war effort. Once the war ended, the US economy took off. With their large production floor layouts and installed equipment base, American businesses emphasized high production runs and high inventory counts.

Educated initially as an electrical engineer and later specializing in mathematical physics, William Edwards Deming helped develop the sampling techniques still used by the U.S. Department of the Census and the Bureau of Labor Statistics. He is also known as the father of the quality movement and was hugely influential in post-WWII Japan. He is most well-known for his theories of management.

American businesses had little need for Deming’s lean philosophy. The Japanese, on the other hand, were rebuilding both their country and their industries. Japanese companies needed to focus on eliminating waste, minimal inventory counts, lean processes, simple concepts, and cost reduction.

One Japanese engineer who took Deming’s principles to the next level was Taiichi Ohno, who eventually developed the Toyota Production System (TPS) alongside Sakichi Toyoda and his son Kiichiro Toyoda. The TPS system was improved throughout the 1950s, 1960s, and 1970s.

Eventually, Masaaki Imai – a Japanese management consultant who studied TPS – introduced Kaizen to western businesses in 1985 when he wrote “Kaizen: The key to Japan’s Competitive Success.” He would eventually establish the Kaizen Institute and use it to propagate the Kaizen message and teachings worldwide.

In the end, Kaizen became prominent because of Shewhart’s PDCA Cycle, Deming’s push for hands-on production employees, and Ohno’s TPS system. So, how does Kaizen work?

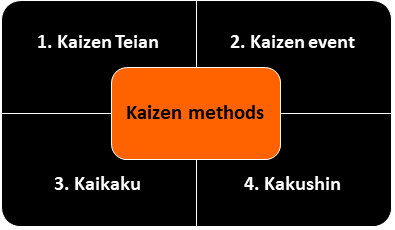

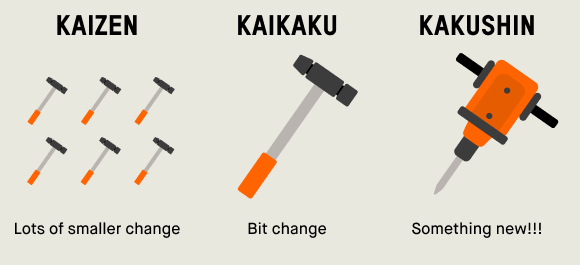

There are four types of Kaizen methodologies. These include Kaizen Teian, Kaizen Events, Kaikaku, and Kakushin. Each one is explained in detail below.

Kaizen Teian refers to the daily improvements that every employee is responsible for. Every employee must always be trying to improve their work processes and workflow. More importantly, every day, all employees – including supervisors and managers – should be focused on eliminating the following eight forms of waste as defined by Kaizen.

While Kaizen Teian refers to the daily responsibilities of all employees, a Kaizen Event is a scheduled period where a specific work process or task is identified as needing improvement. Kaizen events are focused events where management, supervisors, and front-line employees work to improve a predetermined problem. Ultimately, Kaizen events involve more pre-planning, whereas Kaizen Teian is more about all employees’ daily responsibilities for improving workflow.

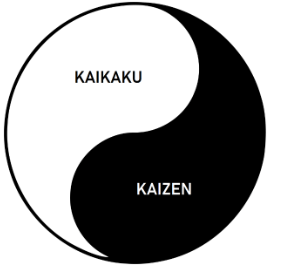

Kaikaku is complementary to Kaizen. When thinking of Kaikaku, think of those instances where a company initiates a complete redesign of processes or procedures. This is an event where a company adopts an entirely different way of doing things. An example is replacing labor-intensive and time-consuming work processes with automated processes like automated equipment and machinery. This move involves in-depth analysis and a willingness to ensure that all work cells can keep up with the increased throughput.

When thinking of Kakushin, think about a technology breakthrough that completely changes how work is performed. A Kakushin event is an about-face and complete change. It can best be described as the ultimate brainstorming session where a company charts a path toward a new culture and way of doing work. An example includes a plastic injection molding company modifying equipment to perform thixomolding magnesium alloys. It can consist of a company adopting additive printing or metal-injection molding (MIM) technology.

You can’t adopt a half-hearted attempt at Kaizen. It can’t be a flavor-of-the-month strategy. Adopting Kaizen requires a top-down and bottom-up mindset where the entire organization is committed to enacting Kaizen principles. So, what type of mindset and approach does your company need to make Kaizen a success?

The entire purpose of Kaizen is continuous improvement. It’s not a one-time event. It’s not just something a company does monthly or quarterly. This is a 24/7 mindset that must be indoctrinated from the highest manager down to the front-line employee. The most significant difference between how North American companies view Kaizen compared to Japanese companies is the idea that Kaizen is a single event for American companies. This is entirely wrong. These companies plan a “Kaizen” event every quarter instead of fully adopting Kaizen every second, minute, and hour of the day.

Your employees must be motivated to change. This means they must be satisfied and buy into the Kaizen mindset. If your workforce isn’t motivated to improve things, then Kaizen is far less likely to improve.

Again, Kaizen requires a company-wide, top-down, and bottom-up commitment to its principles. However, to succeed and become part of a company’s culture, the very top of an organization must push its principles downwards. Once that happens, the entire organization will fully adopt the Kaizen continuous improvement methodology.

Companies must eliminate tribalism and silos. This continuous methodology can only work when teamwork is part of every employee’s mindset. An environment where departments or employees blame each other for lack of progress will never work. The mindset must always be focused on problem-solving. Fostering an environment where teamwork thrives is essential to making Kaizen work.

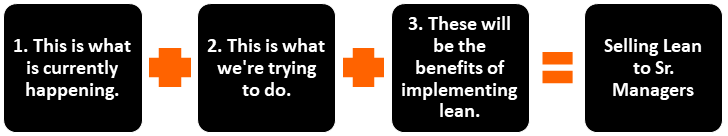

C-level executives and management rarely make decisions based solely on assumptions. Guesswork is not something they adopt or embrace. They make decisions based on irrefutable facts, numbers, and scrutinized data. Selling Kaizen/lean principles to senior management is ultimately about providing them with that all-important data. It’s about giving them the numbers and evidence they need to pursue Kaizen. For this to succeed involves adopting the three-step process outlined below.

This three-step process involves defining the current waste as it exists right now. You can do this on a small scale with a single manufacturing work cell or workstation. The best way to do that is to demonstrate to senior management how the current causes of waste lower cycle times and production throughput. After this, you should clearly define the causes of waste and how it impacts cycle times.

The second step involves eliminating that waste. Once that’s done, your cycle times and production throughput should improve. This is the evidence you’ll need to provide to senior management. It’s the data that shows how eliminating waste increases throughput.

The third and final step is showing management the benefit of adopting these principles across the shop floor at every work cell. To learn more about gathering the data, you need to convince senior management to pursue Kaizen/Lean principles; read: How to Sell Continuous Improvement to Senior Management.

The goal of this approach is to set yourself up for success. Management makes decisions based on data. As a manufacturer, this means how much the company would improve – or produce more – if they adopted Kaizen. For other companies like distributors, it’s about showing how excess inventory erodes profit.

If you must sell a concept to upper management, focus your argument around solving a problem that matters most to them. Then, position yourself to succeed by showing how adopting Kaizen can eliminate or reduce the impact of that problem.

There are a couple of tips and tricks you can adopt as you start your journey toward a fully-adopted Kaizen culture. These are outlined below.

KAIZEN FOAM 20INX40INX2IN 13 LAYER

D-5SFOAM2040

USD$35.00

UTILITY KNIFE

TK-UKNIFE

USD$4.99

UTILITY KNIFE BLADES

TK-UBLADES

USD$4.40

FOAM SPINNER

TK-SPINNERS

USD$4.99

FOAM KNIFE SLED

TK-SLED

USD$16.99

FOAM SCRAPER

TK-SCRAPER

USD$13.99

THIN BLADE KNIFE

TK-TKNIFE

USD$5.50

THIN KNIFE BLADES

TK-TBLADES

USD$3.50

LONG NOSE SILVER MARKER

TK-MARKER-SLV

USD$8.99

You’ll never be wanting in terms of things to improve through Kaizen. Here are some examples of simple Kaizen improvements that provide stable returns.

Lower Inventory Costs: You can reduce your inventory financing costs while eliminating the high costs of inventory obsolescence and damage. Isolating excess inventory on raw materials and spare parts will also help you maximize the square footage of your warehouse.

Reduce Transit Times: Moving parts, materials, and WIP from one location or cell to the next takes time. Poor spacing and long distances increase that time and are, therefore, a waste. Minimizing the transit times to move WIP and materials is a simple way to reduce waste and increase throughput. This simple process creates continuous flow with minimal waste.

Detailed Processes with Images: Employees need well-defined processes. In manufacturing environments, that means using high-quality images demonstrating the correct way to follow a given work process. Use images for each step of the process and always ask for feedback from employees on how it can be improved. Again, Kaizen is a 24/7 improvement process. Employees should constantly be looking to improve everything – as best defined by Kaizen Teian.

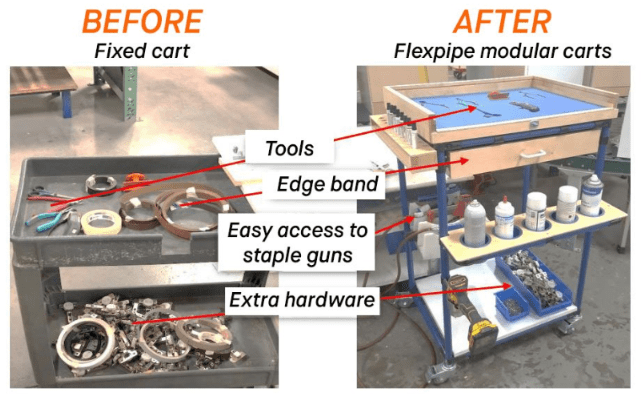

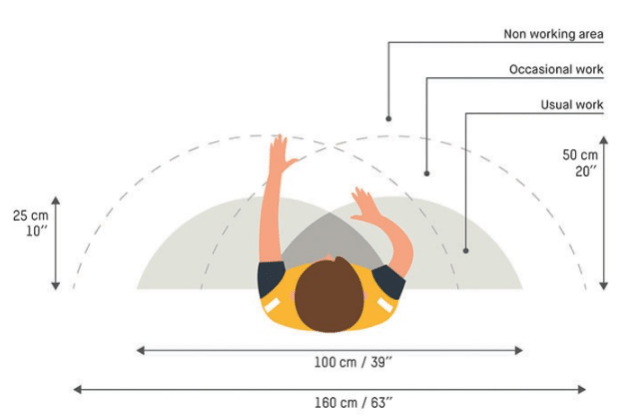

Improved Work Cell Layout: Simple changes like making it easier for operators to reach material without overexerting themselves lead to considerable savings in time while reducing absenteeism due to injury. Most motion improvements are made within the work cell, where employees must immediately access tools, materials, and WIP.

Ergonomics: Making the workplace safer helps to reduce the incidence of worker injury. It also demonstrates an investment on the company’s part toward protecting its employees. This is the best way to show employees that you consider them your most important asset. This can include simplifying movements in work cells, using ergonomic and anti-fatigue matting, and establishing proper lifting procedures for employees.

Flexpipe Inc. is a Montreal-based designer, manufacturer, and integrator of a tube and joint system whose history goes back to the Toyota Production System. The company’s cut-to-length-and-assemble system makes building any material handling or standing structure easy. The company fully embraces Kaizen as a guiding principle, which is demonstrated by every customer the company works with. The tube and joint system empowers companies to build whatever structure – and change that structure – at a fraction of the costs and time of more permanent welded structures. To learn more about how this simple solution works, contact us now. To see how customers have used this scalable and modular system to reduce costs and eliminate waste, please go to Flexpipe Case Studies.