Case Study

PIPE AND JOINT SYSTEM FOR MEDICAL EQUIPMENT MANUFACTURERS

Case Study

HOW HOLOGIC INCREASED ITS PRODUCTION BY 25% WITH MODULAR MATERIAL HANDLING SYSTEM

Case Study

HOW THE MAINTENANCE EMPLOYEE CAN INFLUENCE THE PRODUCTIVITY OF AN SME

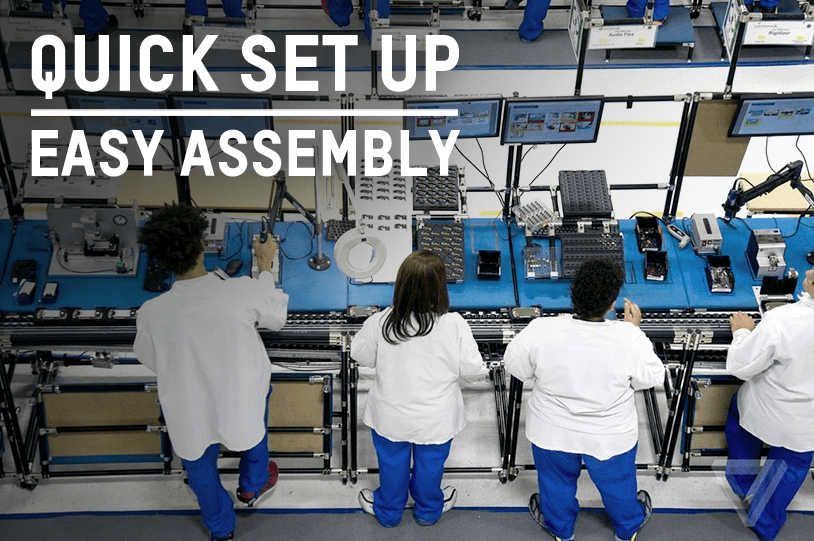

Here are examples of how medical manufacturers use the pipe and joint system for lean manufacturing. Below are several photos of various workstations: U and L-shaped work cells and one-piece flow assembly line, among others.

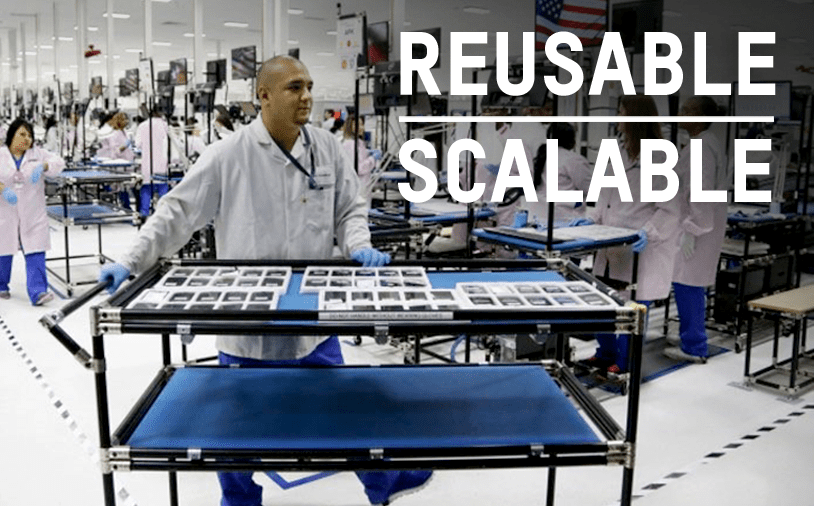

Manufacturers also use pipe and joint systems to build carts for different purposes: WIP, kitting cart, sub-assembly, etc. The structural system can also be used to build custom flow racks and 2-bin systems than can be integrated into the workstations.