Case Study

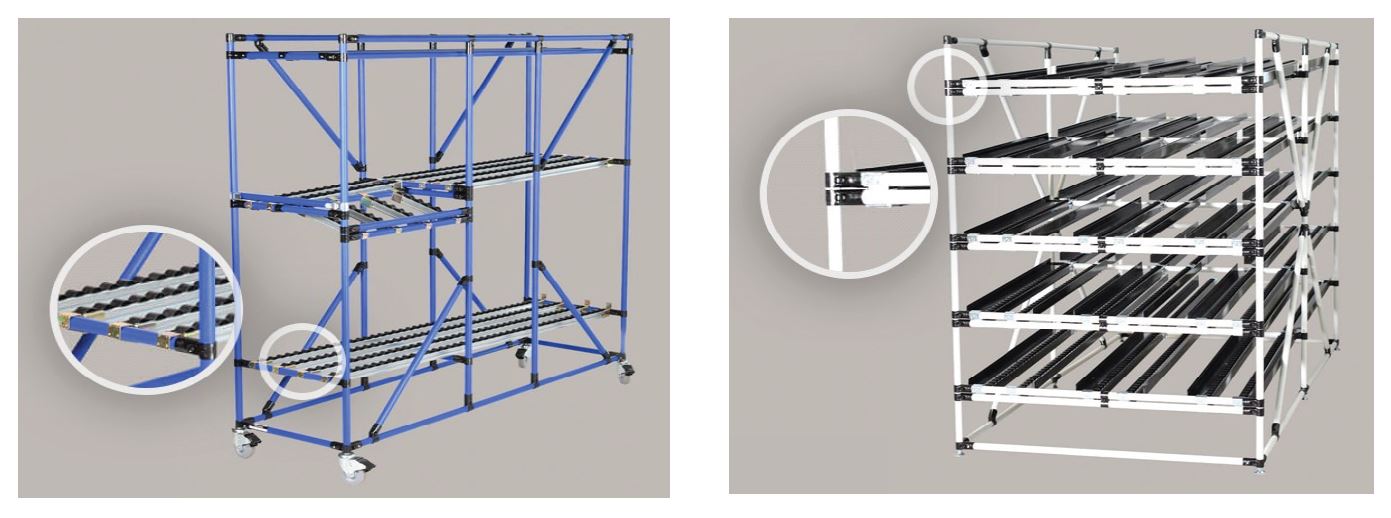

HOW MODULAR CARTS HELP THIS LOGISTICS COMPANY IMPROVE ITS EFFICIENCY

How to build

HOW TO BUILD MODULAR CARTS

Structure

CARTSWe have gathered 8 assembly tips for material handling modular structures regarding the loading capacity. Relevant tips that will save you time and money to ensure your industrial pipe racking system support there intended load.

Estimated reading time: 8 minutes

3-4h

3-4h

Read on to find out our best tips, and don’t forget to download the PDF version for collecting them all!

Increasing the loading capacity of your gravity racks using the following assembly options:

1. Add numerous conveyor tracks to increase the load.

2. Double the front and rear tube support using HJ-1 joint set.

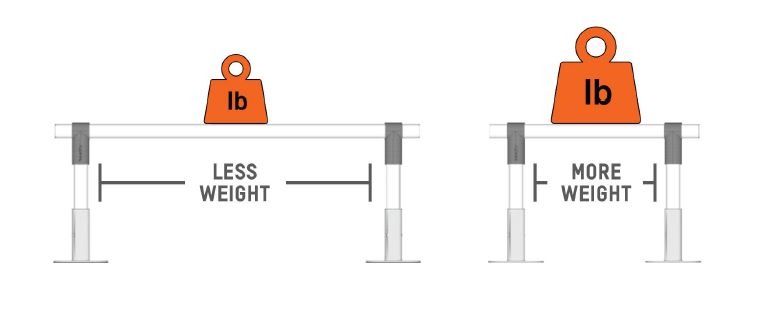

How you design your structure and assemble your Flexpipe structure will affect its loading capacity. The longer the pipe, the less weight it can hold.

![]()

Download the PDF version of the assembly tip #16

To calculate the loading capacity of your modular structures, follow these 3 steps:

1. Take the longest pipe span dimension of your structure.

2. Refer to the Flexpipe loading capacity chart provided.

3. Multiply the weight capacity of each pipe by the number of pipes in the structure.

![]()

Download the PDF version of the assembly tip #17

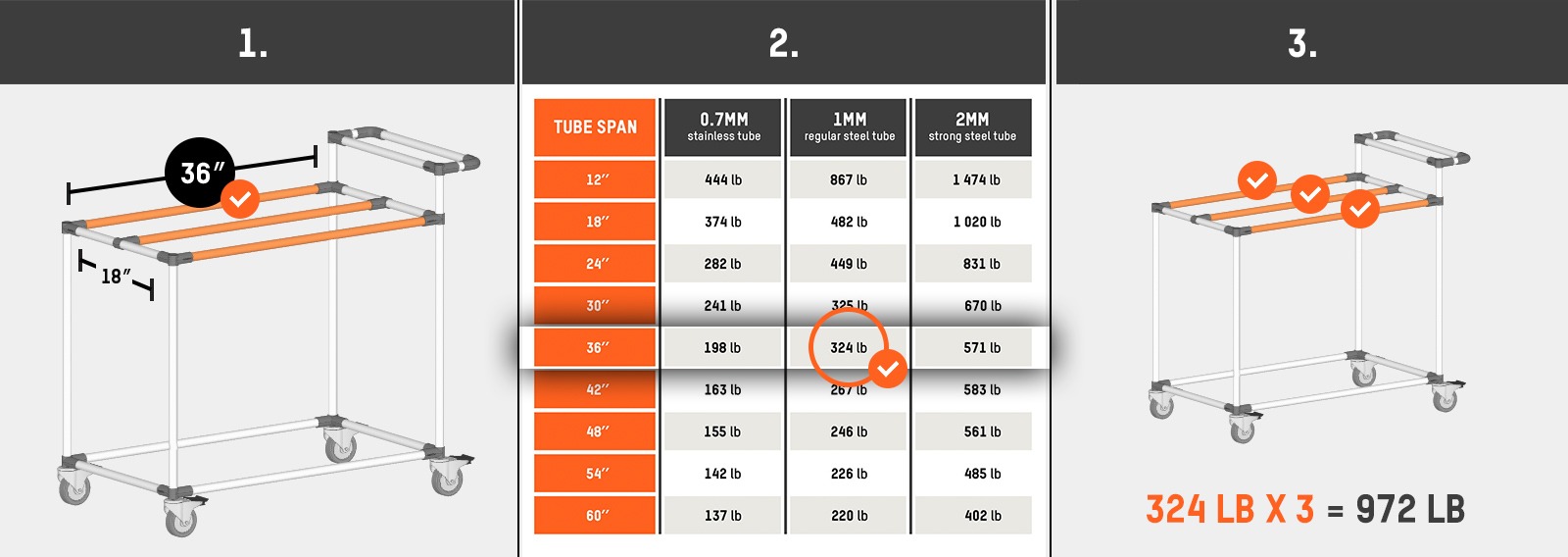

Use the HJ-1 joint set to add column to your modular structure. This option will help increase the loading capacity and reinforce your structure.

![]()

Download the PDF version of the assembly tip #18

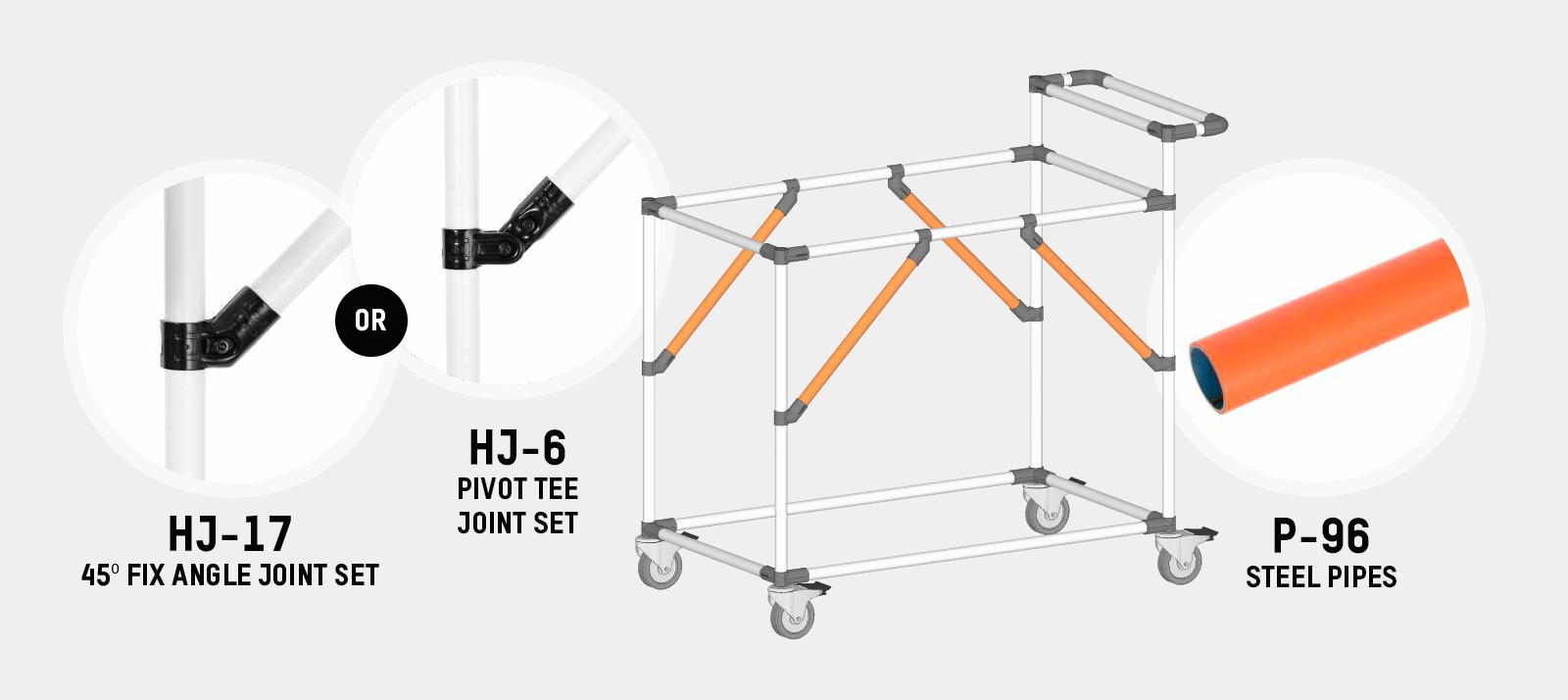

Add angle braces using the HJ-6 pivot angle joint set and HJ-17 fix angle joint set to reinforce your structure’s loading capacity.

![]()

Download the PDF version of the assembly tip #19

Double stack your pipe using the HJ-13 parallel joint set to reinforce your structure’s loading capacity.

![]()

Download the PDF version of the assembly tip #20

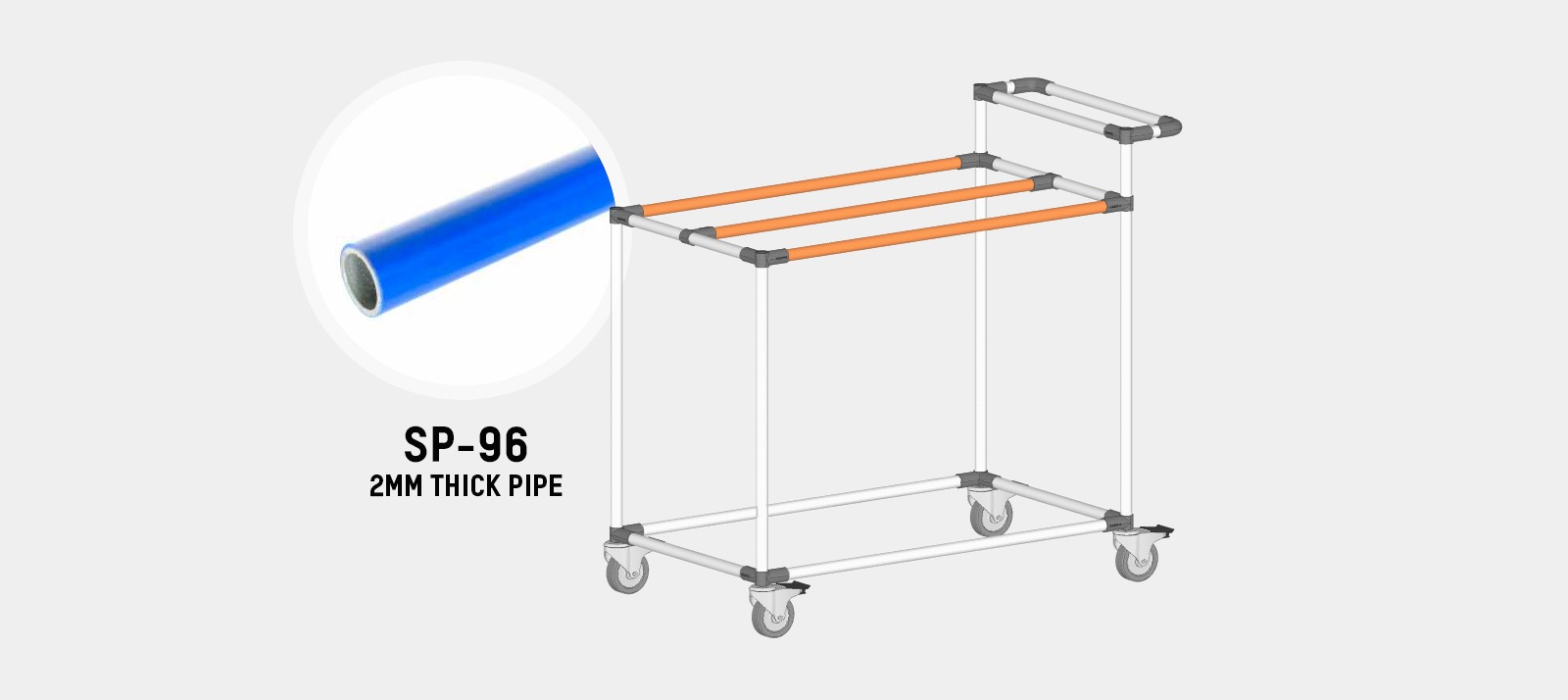

To reinforce your structure’s loading capacity use the thicker 2 mm pipe SP-96-BL.

![]()

Download the PDF version of the assembly tip #21

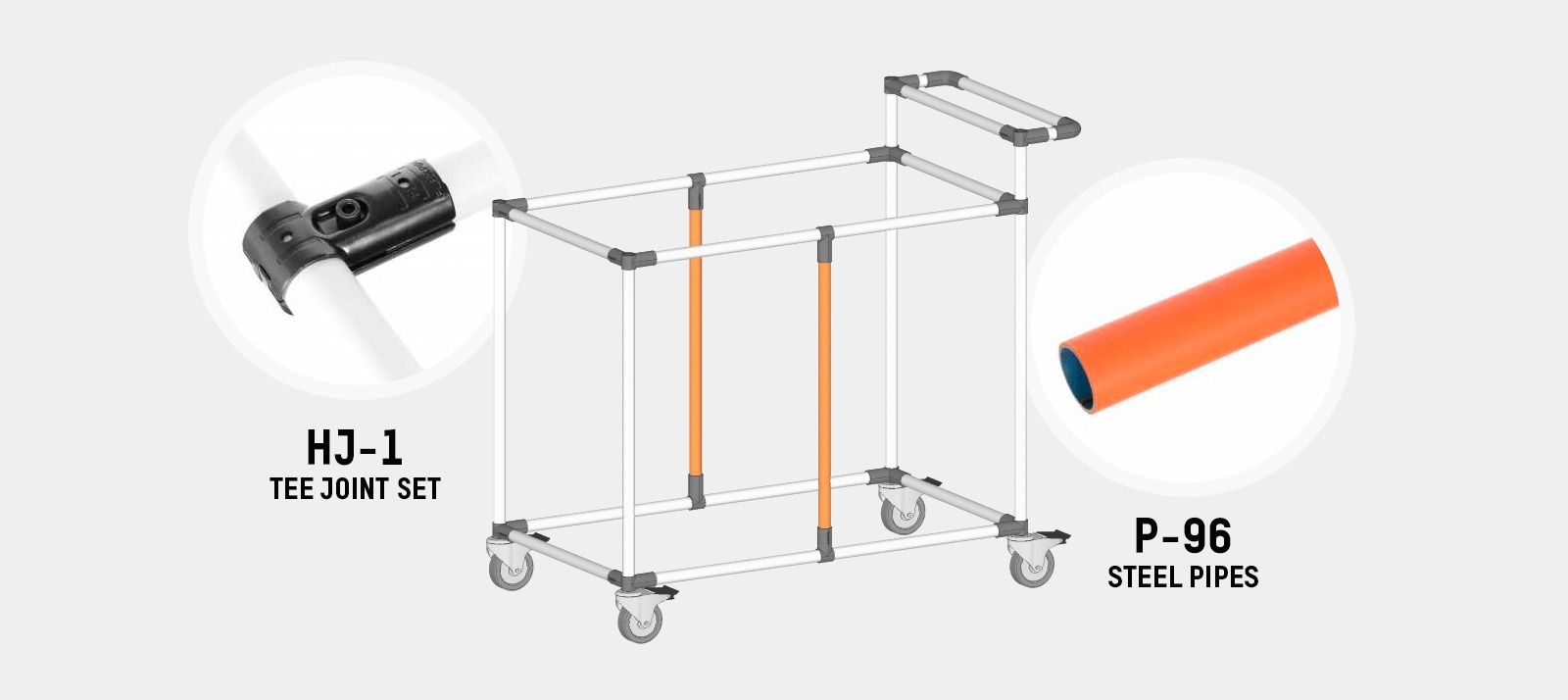

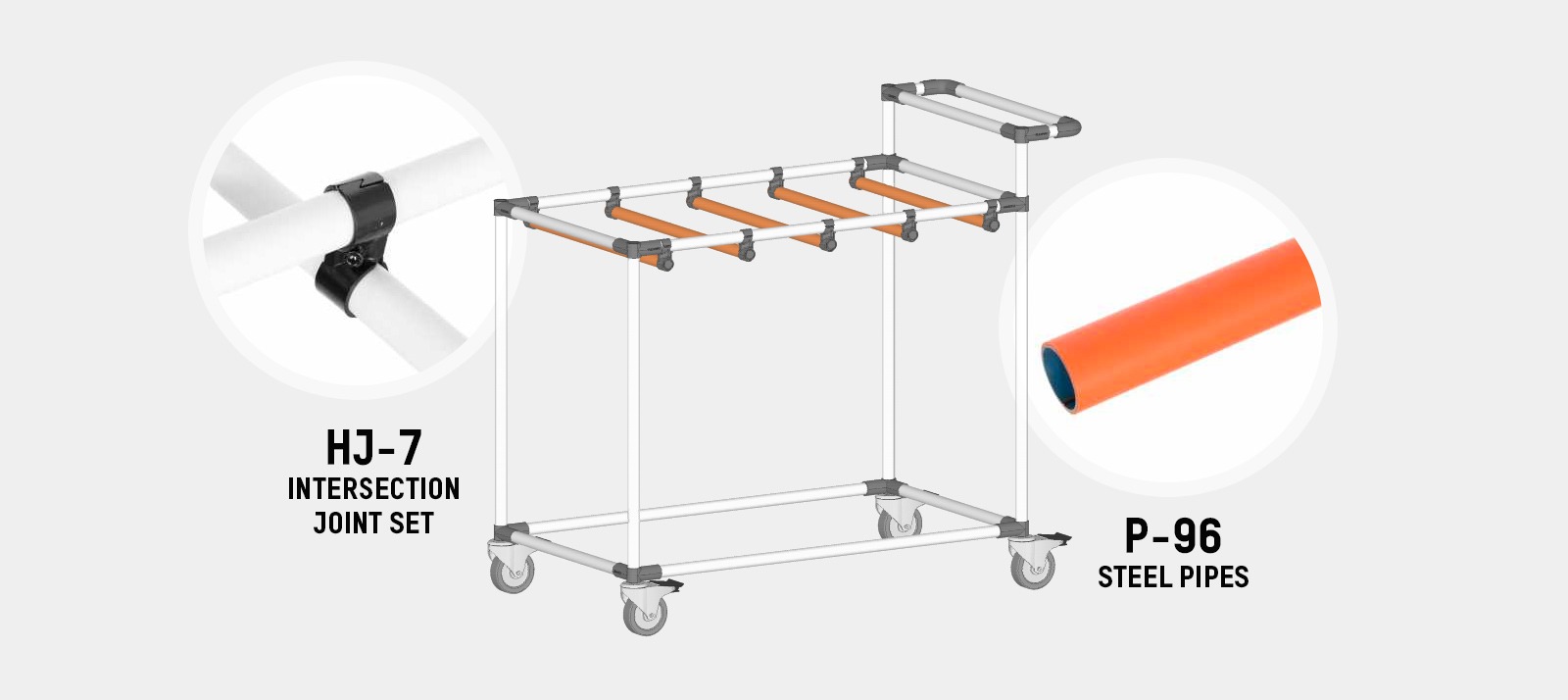

Reinforce your structure’s loading capacity by adding pipes using the HJ-7 joint sets. It also allows to create pipe shelves instead of using a top surface that would cost you hundreds of dollars. Pipe shelving allows a lot of flexibility as you can determine the distance between each tube according to the load and the volume of the equipment handled.

![]()

Download the PDF version of the assembly tip #22