What is the 60 second visual workflow?

In lean manufacturing, the general rule of thumb is that anyone should be able to walk into a workplace and identify the flow of work being done within 60 seconds. One of the easiest and most effective ways to visually accomplish this goal is through the use of 5S floor marking.

The proper use of floor marking tape helps create order and a flow pattern of work in your facility, which eliminates searching and confusion within a work area. Floor marking also helps to define processes and cells in the value stream clearly.

Every industrial workplace is required by OSHA to mark aisles and passageways to guarantee that pedestrians have a designated walkway to pass safely. Forklift drivers must also be aware of their driving lane’s parameters. But 5S floor marking will do more than that.

In a parking lot, the lines make cars park in a certain way, optimizing the space available. Studies have shown that when a lot is covered in snow, 25% fewer vehicles can park.

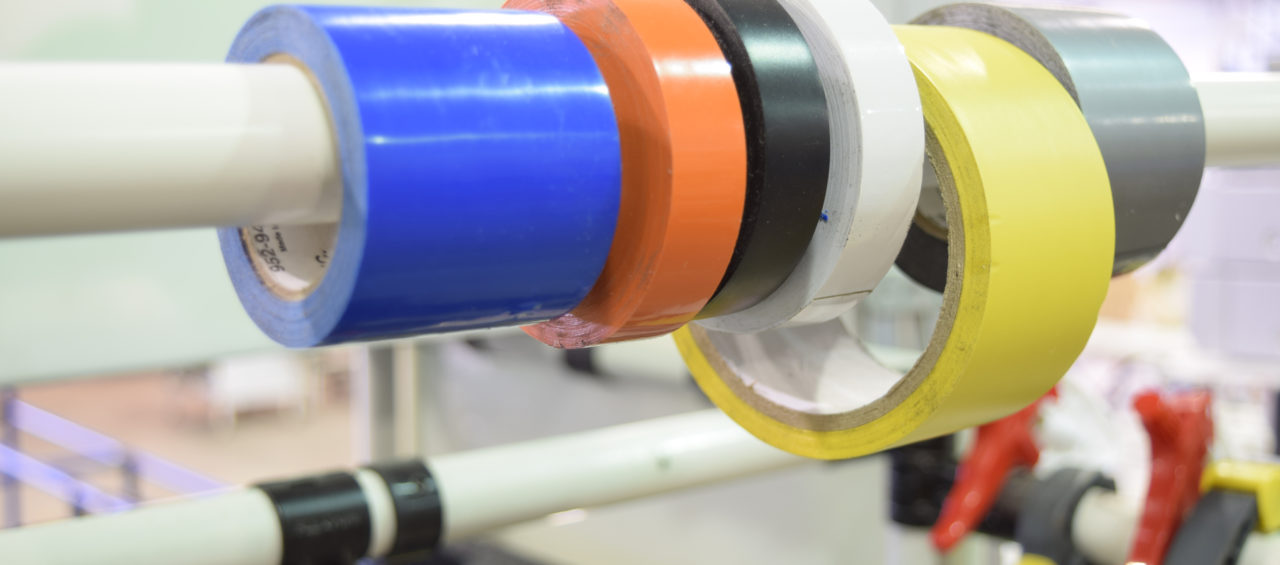

The color scheme below complies with the OSHA 1910.144 standard, which purposefully limits the colors included to encourage natural learning and easy recognition of specific areas in the workplace. However, it can also be easily modified to suit the particular operational priorities, processes, and characteristics of individual facilities.

There are many pieces of equipment on wheels (machinery, carts, racks, workstations, boards, etc.), allowing flexibility. However, they can easily be moved, which potentially increases searches and confusion—floor marking with color codes and signage help to reduce this potential problem.

5S Floor Marking Color Scheme (Developed by Brady Corporation)

Yellow

Alleyway, traffic lanes, and work cells.

White

Equipment and fixtures (workstations, carts, floor stand, displays, racks, etc.) not otherwise color-coded.

Blue, green and/or black

Materials and components, including raw materials, work-in-progress and finished goods.

Orange

Materials or products held for inspection.

Red

Defects, scrap, rework, and red tag areas.

Red and white

Areas to be kept clear for safety/compliance reasons (e.g., areas in front of electrical panels, fire fighting equipment, and safety equipment such as eyewash stations, safety showers, and first aid cabinets).

Black and white

Areas to be kept clear for operational purposes (not related to safety and compliance).

Black and yellow

Areas that may expose employees to physical or health hazards (e.g., flammable or combustive material containers); Indicates that extra caution should be exercised when entering and working in the area.

Additional marking codes can be done for recycling, trash, and finished goods but use as few colors as possible. This will make it easier for employees to remember the intended meaning of each color.

Floor marking goes beyond simple line tape:

Arrows to create a flow.

Corner marker for temporary object placement such as pallets.

The footprint for foot traffic.

Dense traffic areas with extra protection.