Post

FOUR BENEFITS OF KARAKURI IN LEAN OPERATIONS

Post

BORROWING LEAN MANUFACTURING CONCEPTS FROM THE AUTOMOTIVE INDUSTRY

Post

EASY STEPS TO SUCCESSFUL VALUE STREAM MAPPING

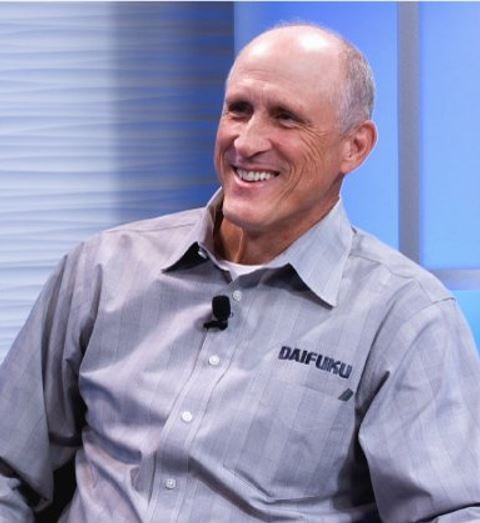

In this interview, Bruce Buscher, VP of Daifuku’s AGV group answers all the questions you may have about all the benefits of having an AGV in your facilities.

An automated guided vehicle (AGV) is a computer-controlled vehicle used to carry or tow materials in a manufacturing facility. In this video, Bruce Buscher, vice-president of Daifuku’s AGV group, explains why AGVs are a great solution for your assembly line and how you can integrate them with your material handling system.

The biggest advantage of using automated guided vehicles on your assembly line is flexibility. Traditional assembly lines are made up of structures such as towline conveyors and overhead conveyors that are permanently attached to the floor, making it difficult to change the configuration of the line after installation. By contrast, on an assembly line made up of AGVs, the vehicles carry the materials from station to station, and the path they follow can be modified at any time to suit different production requirements. This opens up a world of possibilities for your workflow, enabling you to maximize efficiency and reduce waste.

For instance, you’re no longer restricted to following a straight line. According to the rules of circular manufacturing, straight-line processes create waste by forcing workers to travel from one end of the warehouse to the other at the end of each cycle. With an AGV assembly line, you can organize your workflow in whatever shape makes the most sense for a particular process, whether that’s a U shape or a Christmas-tree pattern with deviations for additional tasks such as quality checks and customizations.

Using AGVs also eliminates the need for a human to deliver parts to the assembly line, which means operators are more likely to receive parts at the precise moment they need them. This can help you achieve more consistent cycle times and adjust takt times as needed to meet customer demand.

For maximum flexibility in your workflow, it’s best to pair AGVs with a tube and joint system. Load handling frames built from tubes and joints are relatively inexpensive and can be easily configured to carry parts of varying shapes and sizes, which makes them a popular choice in many manufacturing environments. According to Bruce, the use of AGVs with tube and joint products is especially common in supermarkets and line of sight delivery systems. It’s easy to see why: to fully take advantage of the flexibility offered by AGVs, you’ll need material handling equipment that’s equally adaptable. For example, you might decide to consolidate your workflow and reduce the number of stations on your assembly line. If your load handling frames are made of welded steel, it’s going to be time-consuming and costly to replace them, whereas tube and joint frames are designed to be reconfigured at will.

There’s no need to overhaul your entire assembly line in one go. If you’re not sure where AGVs would best fit into your workflow, you could start by identifying areas of waste or reduced productivity (creating a value stream map is a great way to do this) and assess whether an automated guided vehicle could solve the problem. For instance, you might notice that one of your operators always has to wait for parts to arrive at their workstation before they can begin their task, which creates a bottleneck in your production chain. The solution might be to program an AGV to deliver the required parts precisely when the operator needs them. Alternatively, you could search for a way to reduce the time your workers spend moving pallets through the warehouse. AGVs can help with that, too.

In short, whether you’re looking to streamline your entire operation or make a few small adjustments to achieve a leaner workflow, AGVs are an excellent tool to have at your disposal.

Mr. Buscher has been leading the charge to automate manufacturing and assembly processes for more than 40 years. He first started as an engineer on the plant floor and has been the VP of Daifuku’s AGV group for the last fifteen years. Bruce and his team developed a full line of standard AGV Products and Navigation Technologies to solve Assembly Line challenges and drive out costs. They have deployed AGV’s in assembly lines across all industries.

Daifuku uses AGV’s to solve basic issues such as Ergonomics, Safety, Workforce Turnover, and Cost Reductions. As the oldest AGV manufacturer in North America, Daifuku has continuously led the way in automating assembly lines over the last 100 years and doing it with AGV’s since 1962.