Article

QU’EST-CE QUE LE FLUX DE TRAVAIL VISIBLE EN 60 SECONDES ?

Article

10 ASTUCES POUR DONNER VIE AU TRAVAIL STANDARDISé

Article

MON EXPéRIENCE AVEC LE NETTOYAGE

En tant que fabricant, un de vos plus gros avantages compétitifs est d’éliminer les gaspillages. C’est-à-dire les actions qui sont superflues et sans valeur ajoutée. Les shadow boards sont un excellent moyen d’implémenter les principes d’amélioration continue, puisqu’ils contribuent justement à éliminer les 8 gaspillages manufacturiers. Cet article vous sera utile pour mettre de l’ordre et faire le tri dans vos outils de travail afin d’effectuer vos tâches efficacement au quotidien, et ce, peu importe la nature de votre travail.

ORGANIZE TO OPTIMIZE: UP YOUR KAIZEN GAME WITH 5S FOAM TOOLS

FREE WEBINAR - Wednesday, August 30, 2023 - 1 pm EDT

Selon la méthode 5S, le shadow board est un moyen couramment utilisé pour la gestion visuelle des outils dont on se sert plus d’une fois par jour. C’est une approche très intéressante, car elle s’applique à presque n’importe quel environnement!

Un shadow board est un moyen visuel de stocker des objets, en utilisant l’ombre de chaque outil sur fond coloré pour indiquer où celui-ci devrait être replacée après chaque usage.

On retrouve le shadow board davantage dans le 2e S : SITUER ou bien « SEITON » en japonais. La définition exacte de ce terme est de disposer les objets et mettre chacun d’eux à sa place. Établir un espace réservé pour chaque outil, ou chaque pièce d’équipement vous aidera à pouvoir trouver ce qu’il faut quand il le faut.

Vous réaliserez un gain d’efficacité en réduisant considérablement les gaspillages à non-valeur ajoutée, tels que le temps perdu à chercher un tournevis, un balai ou une paire de ciseaux.

Bon à savoir – Pour un contrôle visuel optimal de vos pièces et outils, voici les 3 éléments-clés d’un shadow board:

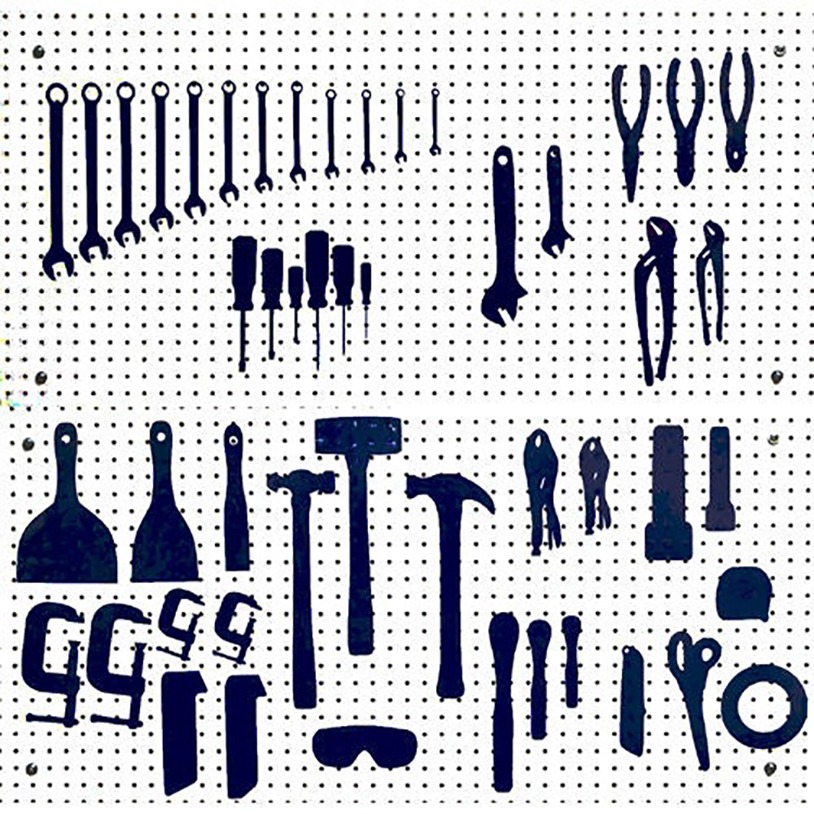

Typiquement, le shadow board a comme base un panneau perforé (pegboard) sur lequel l’on aura tracé le contour ou peint la forme de l’ombre des outils qui y sont accrochés. Les shadow boards sont un moyen efficace de créer un impact visuel immédiat en raison du fond coloré. Ils peuvent être utilisés autant pour des outils de travail que pour des pièces de production, comme des matrices ou prototypes, à titre d’exemple.

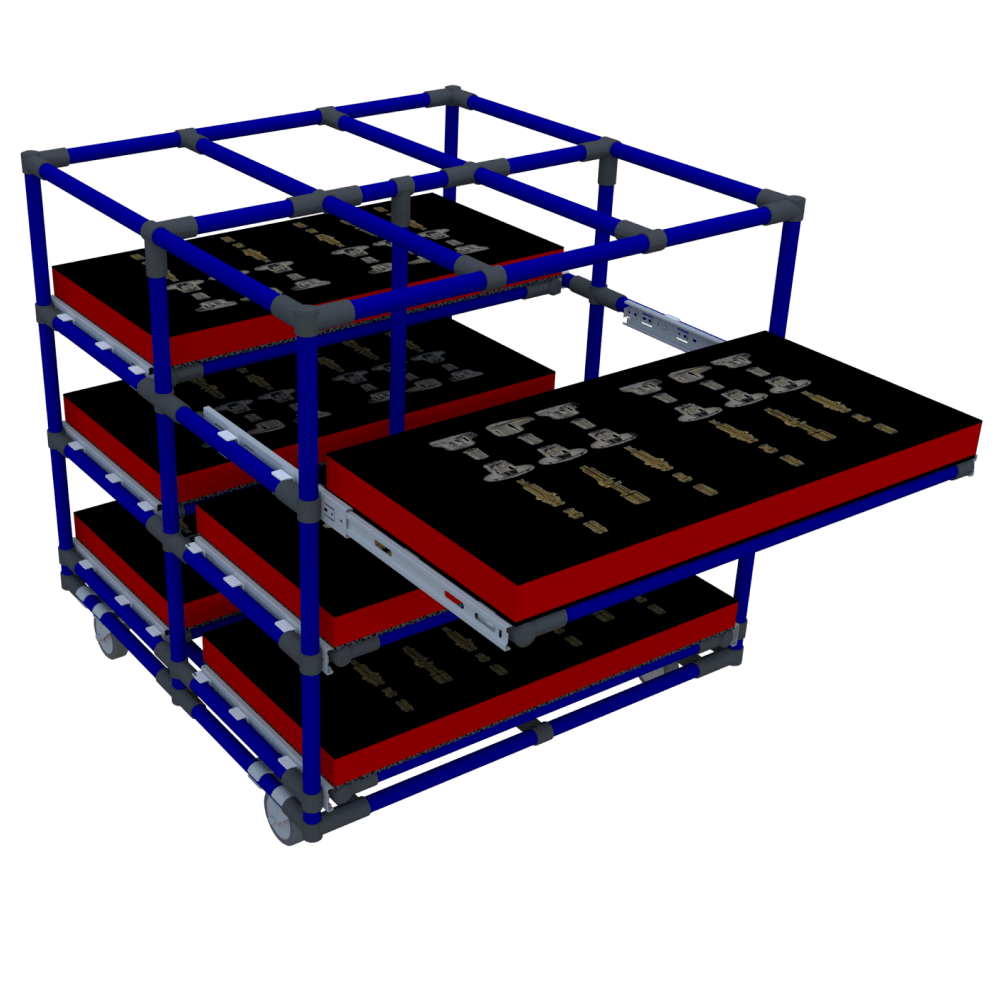

L’exemple photographié ci-dessous représente des chariots de kitting que l’un de nos clients emploie avec son fournisseur afin d’éviter le suremballage et le surplus de déchets sur les chaines de fabrication.

En renvoyant ces boîtes à son fournisseur, ce dernier peut les remplir à nouveau avec la marchandise commandée et ainsi ne pas devoir se réapprovisionner en emballage lui aussi.

En plus d’être écologique, cette méthode prévient tout oubli de pièce de la part du fournisseur et peut également l’aider dans sa préparation de commande. Le code de couleur utilisé aide à identifier rapidement les pièces manquantes.

Cette section de l’article vous fournira des astuces ainsi que des étapes de fabrication pour déterminer quel genre de shadow board sera le plus efficace et profitable pour vos besoins d’entreprise.

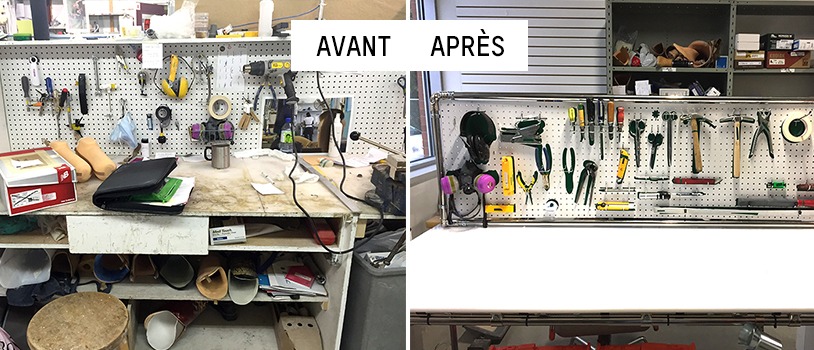

Tout d’abord, rassemblez tous vos outils afin de déterminer lesquels auront leur place sur votre shadow board. Pour vous aider à choisir ceux dont vous avez besoin pour accomplir votre travail, pensez à la mise en scène d’une salle d’opération dans un hôpital. Un chirurgien ne devrait jamais avoir plus que les instruments nécessaires à la manoeuvre qu’il s’apprête à faire ni avoir à faire la chasse au scalpel.

Afin d’éviter des pas inutiles, vous devriez toujours disposer vos outils le plus près de votre poste de travail. Normalement, ce seront des outils utilisés dans la même journée ou dans l’heure. Dans le cas d’un bureau, les mêmes principes s’appliquent : les objets fréquemment employés doivent y être placés dessus.

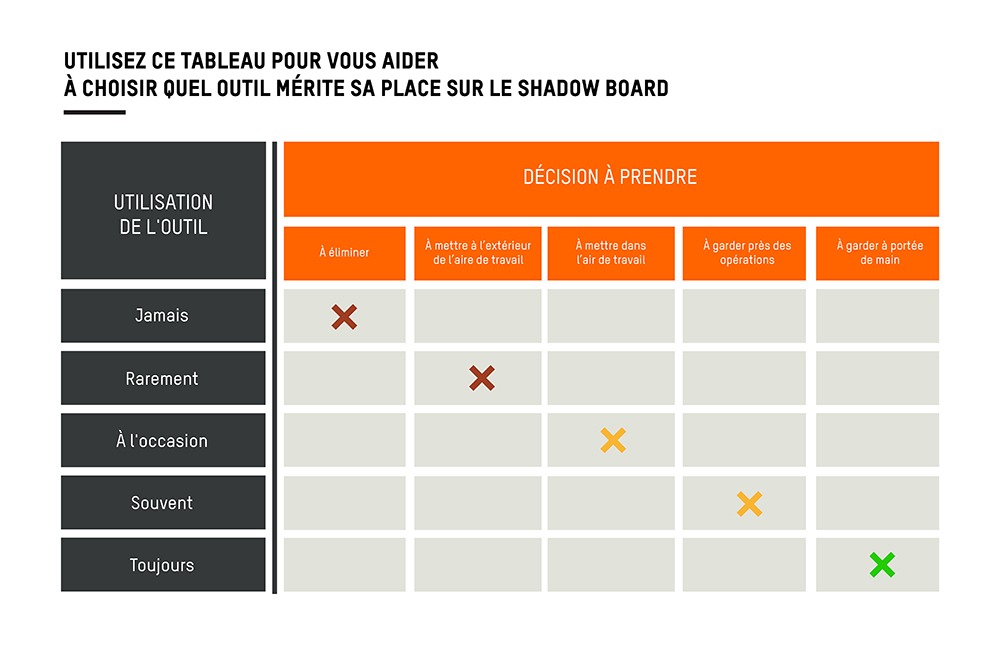

Voici un tableau qui devrait vous faciliter la tâche pour déterminer si l’outil en question mérite sa place sur le shadow board ou non.

Une fois que les outils qui doivent être à portée de main sont choisis, il faut songer au support convenable sur lequel les placer. Le nombre d’outils ainsi que l’endroit désigné du shadow board sont deux facteurs déterminants à cette étape.

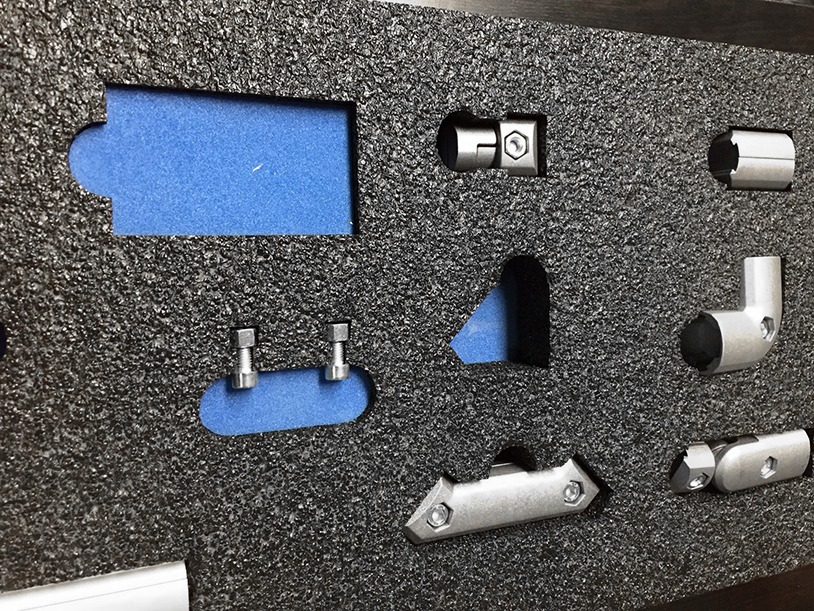

Voici quelques exemples de shadow boards de nos clients pourraient vous inspirer. Certains ont opté pour la méthode simple en utilisant ce qu’ils avaient sous la main dans l’usine, alors que d’autres ont faire faire une découpe au laser dans un compartiment en mousse.

Nous recommandons fortement un de nos fournisseurs si ce type de shadow board vous intéresse : OSAAP AMERICA.

Cette entreprise du Maine, aux États-Unis, fabrique – entre autres – des tableaux en divers types de mousse, pour la plupart coupé au laser pour une meilleure précision. Curieux de voir comment ils procèdent? C’est par ici.

Polyéthylène à haute-densité (HDPE)

Le HDPE est une surface de polyéthylène blanc à haute-densité de 1/4 de pouce d’épaisseur. Ce type de matériau est rigide, la haute densité de ce produit le rend incassable et ultra durable. Cette surface se coupe facilement avec une scie adéquate. Pour en savoir plus, référez-vous au produit D-PEGW-481/4 sur la boutique en ligne

MASONITE

Les panneaux perforés en Masonite sont les plus connus sur le marché. On peut généralement les trouvés dans les quincailleries ou magasins de rénovation à grande surface. Peu coûteux, ces panneaux sont munis de trous de 1/8 pouce, ou 1/4 pouce pour un usage plus robuste.

Le Masonite n’est pas conçu pour y accrocher des outils lourds, comme des perceuses. Si un tel poids y est suspendu, le panneau pourrait se déformer et finira par se déchirer. Avec le temps, les trous du panneau peuvent s’abîmer à la suite des changements fréquents de crochets.

L’image ci-dessous montre divers types de crochets que vous pouvez utiliser pour accrocher vos outils.

Astuce: Chez Flexpipe, nous utilisons tout simplement des vis avec boulon pour une meilleure solidité.

MÉTAL

Gage de longévité, le métal est facile à nettoyer et est l’un des matériaux les plus solides sur le marché. De plus, le métal confère une allure stylisée au panneau perforé. Il faut noter que les panneaux en métal sont les plus coûteux et que leur poids les rend difficiles à obtenir en grand format.

De plus, si l’air ambiant est humide, l’on devra envisager l’utilisation d’acier oxydable afin d’éviter toute apparition de rouille. Comme le métal conduit l’électricité, des mesures devront être prises pour enrayer tout risque dans l’environnement de travail.

ACRYLIQUE

Fabriqués de plastique ou d’acrylique copolymère, les panneaux perforés en acrylique offrent une versatilié et une résistance inégalée. Ils sont beaucoup plus légers. Ils sont beaucoup plus légers que ceux en Masonite ou en métal.

Leur durabilité est imbattable, car ils ne rouilleront, fendront et ne se déformeront pas. Ce type de panneau peut supporter des charges importantes.

Chacun de ces matériaux présente des avantages et inconvénients. Il s’agit de les examiner afin de choisir le matériau qui répond le mieux à vos besoins.

Vous pouvez également faire vos shadow boards en mousse si, par exemple, vous avez des pièces fragiles à y mettre. Généralement, ces types de shadow boards seront utiles lorsqu’une manutention de pièces est nécessaire sur la chaine de montage. Vous remarquerez que la majorité de ces shadow boards ont été disposés dans un chariot ou un rack sur roues.

Si vous décidez de construire un shadow board à partir d’un panneau de mousse, plusieurs options de matériau s’offrent à vous. Plus la mousse est poreuse, plus elle sera difficile à découper, comme c’est le cas de l’Ethafoam par exemple. De plus, elle risque de se désagréger plus rapidement aux endroits où vous aurez passé le couteau, la longévité de votre shadow board s’en retrouvera donc écourtée. En revanche, le coût du shadow board sera moindre.

Les panneaux de mousse de classe A, telles que le Crosslink, sont de meilleure qualité en raison de leur haute densité. Ce type de mousse protégera davantage vos pièces fragiles.

Un shadow board peut également être construit avec des matériaux que vous avez déjà à votre usine. Certains de nos clients ont utilisé des panneaux de MDF et d’autres, des panneaux d’acier. Un peu de créativité alliée à un esprit de récupération de matériel peut donner des résultats franchement impressionnants!

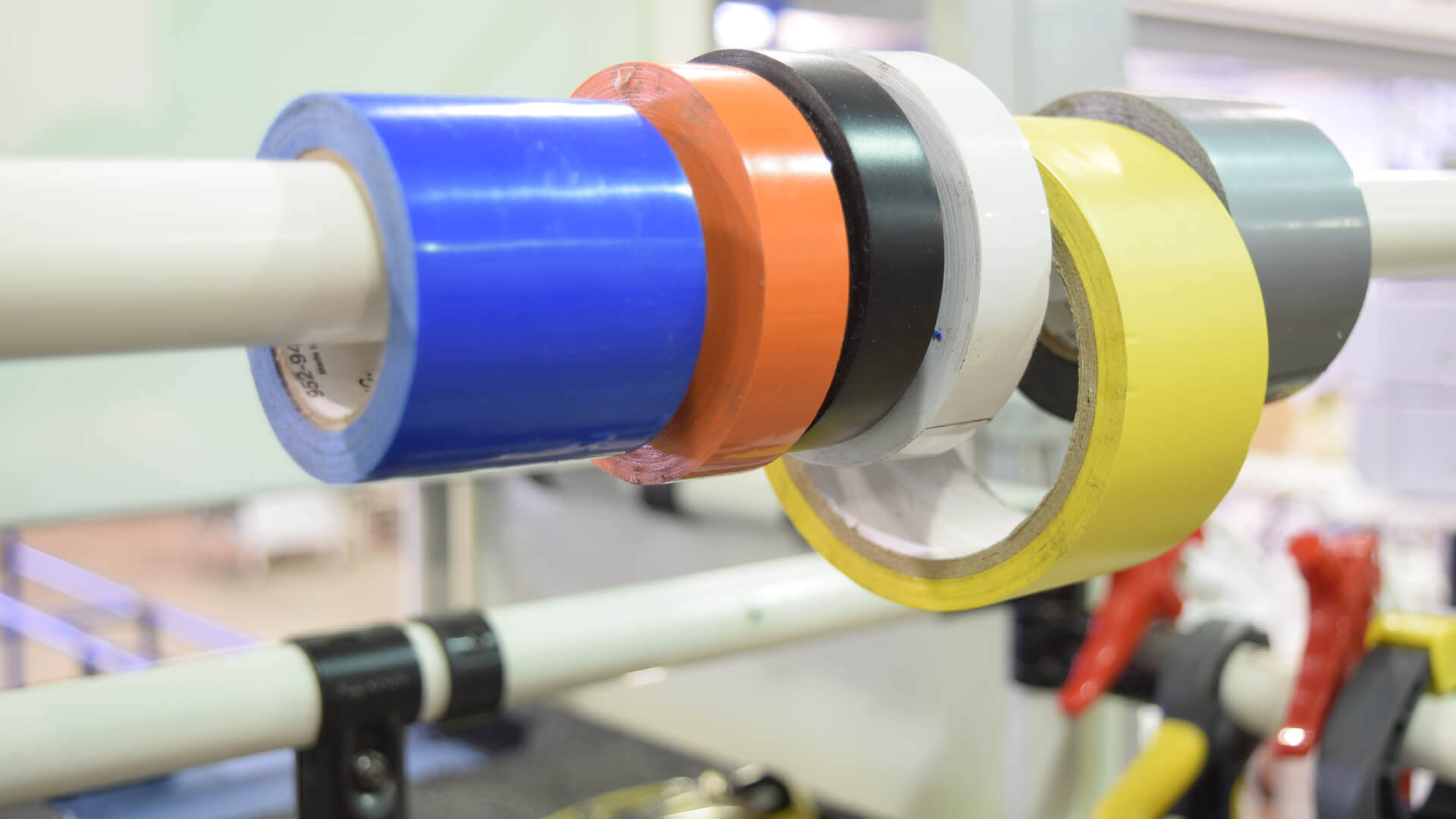

Astuce: Peu importe le support choisi pour votre shadow board, nous conseillons fortement de le séparer en sections distinctes. Il sera plus facile de modifier la section ciblée advenant le cas que vous deviez éventuellement changer la sélection d’outils. Cela évitera de devoir tout refaire votre panneaux!

Pour commencer, disposez vos outils sur le panneau afin de déterminer la meilleure organisation de l’espace possible. Cette étape peut sembler laborieuse, car vous devrez probablement essayer quelques configurations avant de trouver celle qui convient le mieux.

Prenez note qu’il faut s’efforcer de bien aligner les outils. Nous suggérons de les regrouper par famille : clés à molette, marteaux, tournevis, mèches à perceuse, pinces, etc. Ensuite vient le moment de dessiner le contour de vos outils à l’emplacement choisir sur le panneau.

Pour terminer, il ne vous reste qu’à placer vos crochets pour suspendre vos outils et d’y accrocher ces derniers. Prenez une photo du résultat et présentez votre projet au reste de votre équipe afin que tous puissent appliquer cette méthode de travail!

En somme, l’implantation de la méthodologie 5S dans vos installations apportera de nombreux gains et effets positifs à votre entreprise. Vous remarquerez plusieurs bienfaits associés à l’utilisation d’un shadow board tels que:

Que ce soit dans les bureaux administratifs ou encore sur les postes de travail de la chaîne de production, tous y seront gagnants. Alors n’attendez pas un instant de plus!

improve your productivity with kaizen foam

The Perfect Solution for Your Shadow Boards.