Post

CIRCULAR MANUFACTURING: THE RULES OF THE CIRCLE

Post

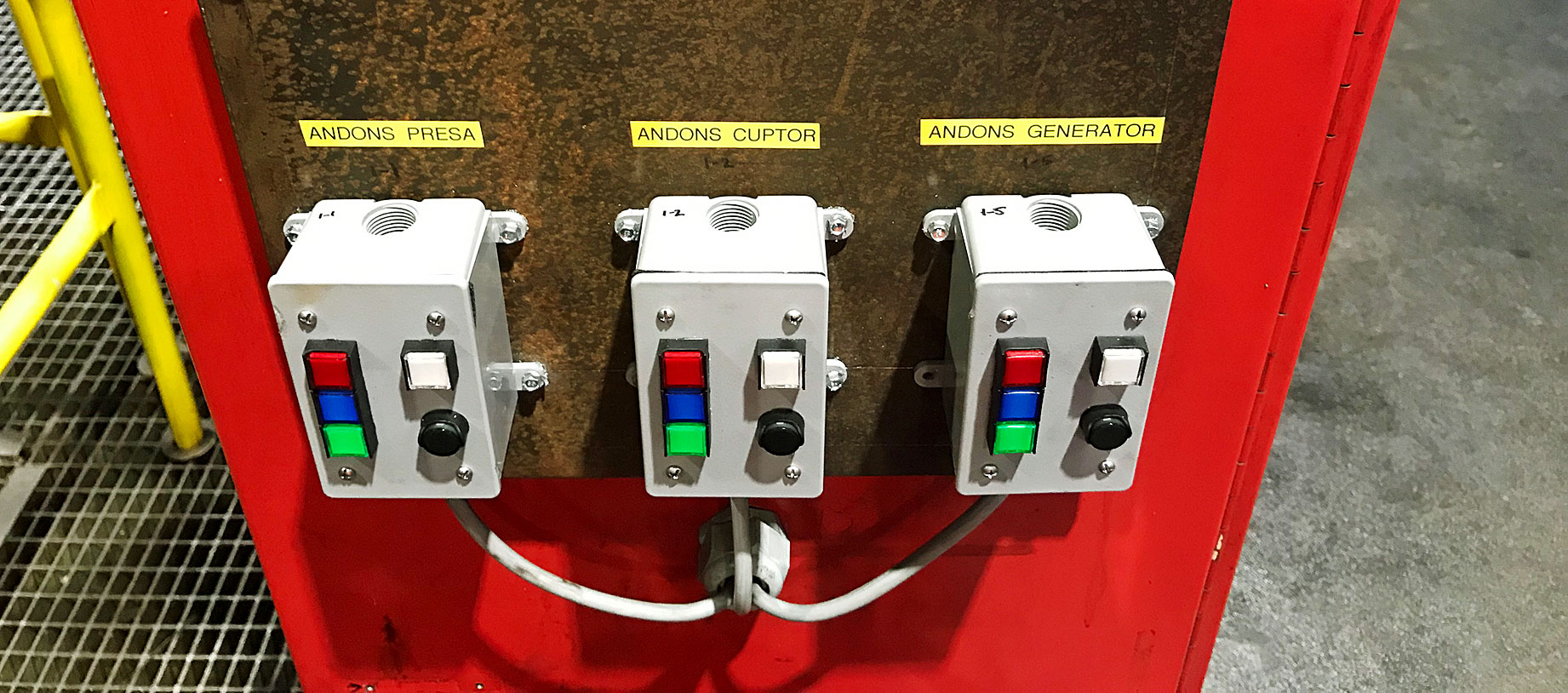

HOW THE ANDON SYSTEM CAN HELP PRODUCTION FLOW

Post

TIPS FOR A SUCCESSFUL KAIZEN EVENT

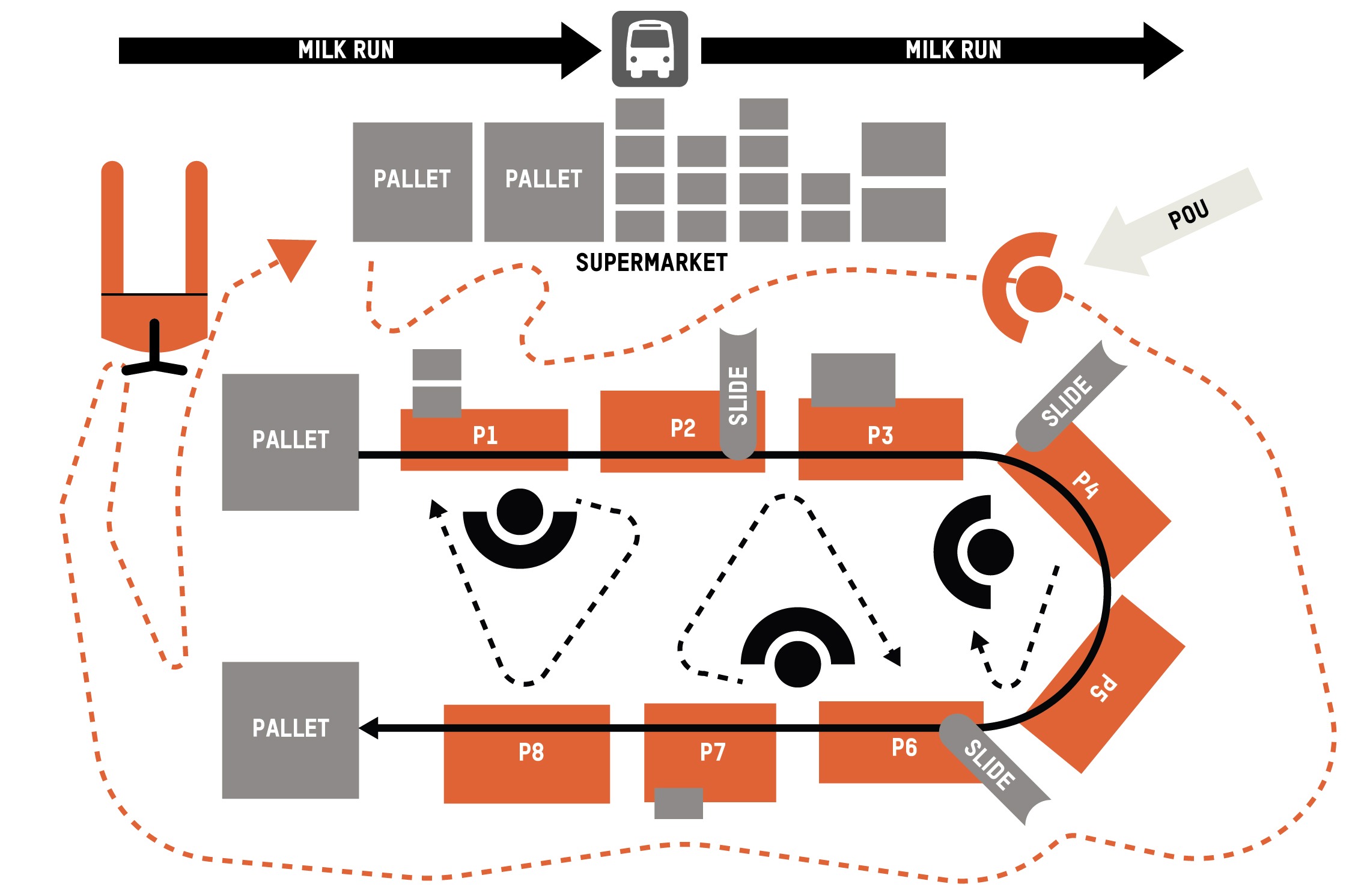

Circular manufacturing is a system for maximizing system flow and productivity while reducing waste in a manufacturing or logistics site.

In this video, Robert Simonis, principal consultant at KCE Consulting, explains how material flow is a key element in circular manufacturing.

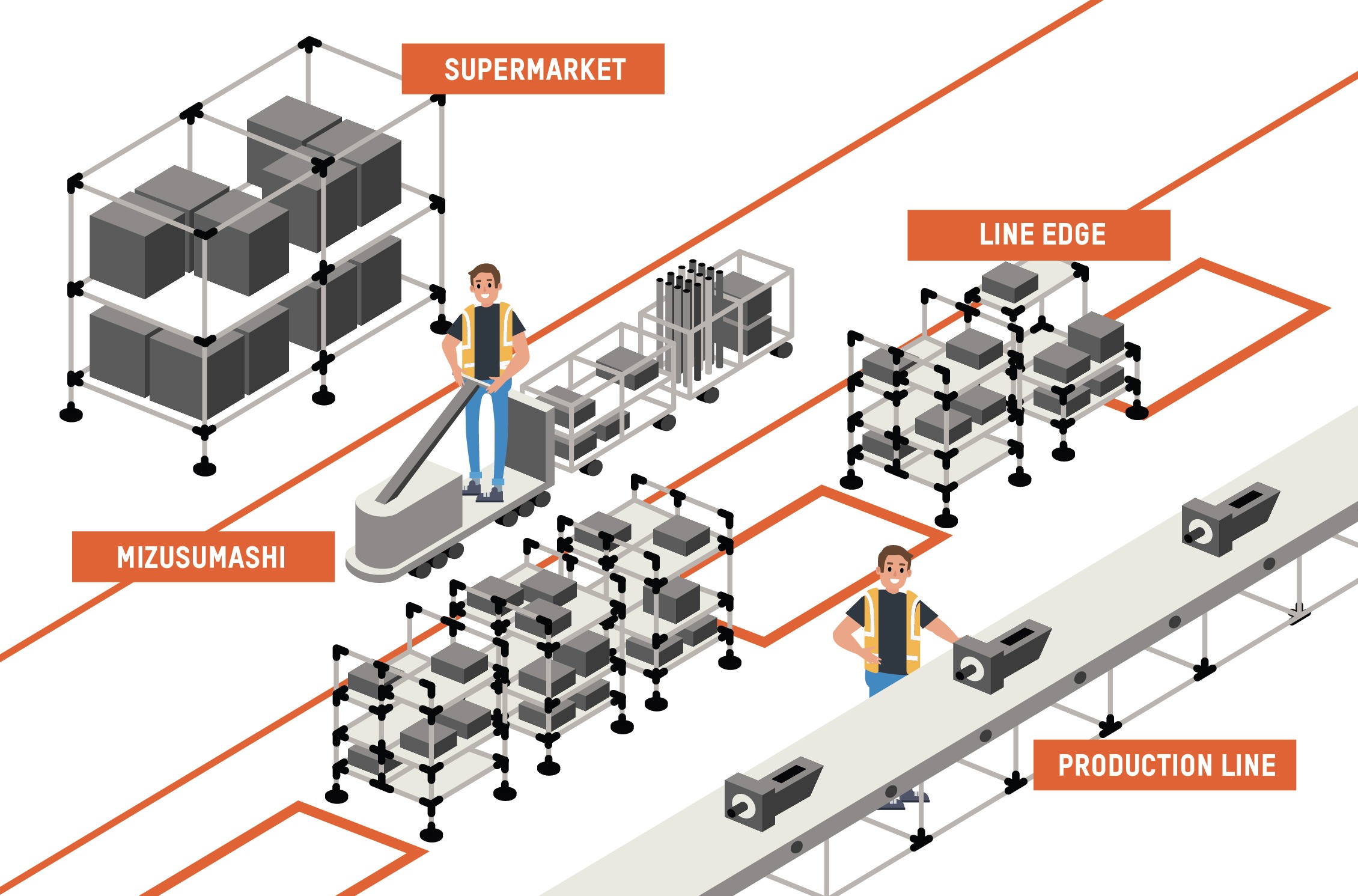

Waterspider, or mizusumashi, is a term that refers to a specific person whose main job is to take care of tasks such as supplying material at workstations, cells, or the point of use. The material handlers allow the other workers to carry out their value-added tasks without distraction, thus enhancing the productivity of the chain and the accomplishment of standardized work in standard time.

Implementing a waterspider system takes time, it’s a process of continuous improvement that needs constant observation, testing and adapting to create the standardized work that ensures the right material at the right time and right place.

Once the rhythm of the waterspider’s activities has been established and mastered, the benefits come into play: it brings a steady pace to the production process, regulating the workflow and avoiding the vicious cycle of sprints and rest. The workers benefit from steady work, less stress and are therefore able to keep their level of energy higher.

Typically, keeping 2 hours or less of material in the cell and resupplying every hour is optimal. It gives the production process a buffer of an hour, which makes it possible to compensate when a production cycle is a few minutes early or late because of unexpected problems. Steady resupply also standardizes and minimizes the space needed for material in the workspace, and helps minimize the operator cycle time.

The buffer makes it possible to cover for variation caused by the material delivery, scrap, quality, and other sources. The operator never has to wait for material or take time to signal for material resupply and is able to optimize productivity.

To control how much material is in the cell, a steady resupply cycle has to be established.

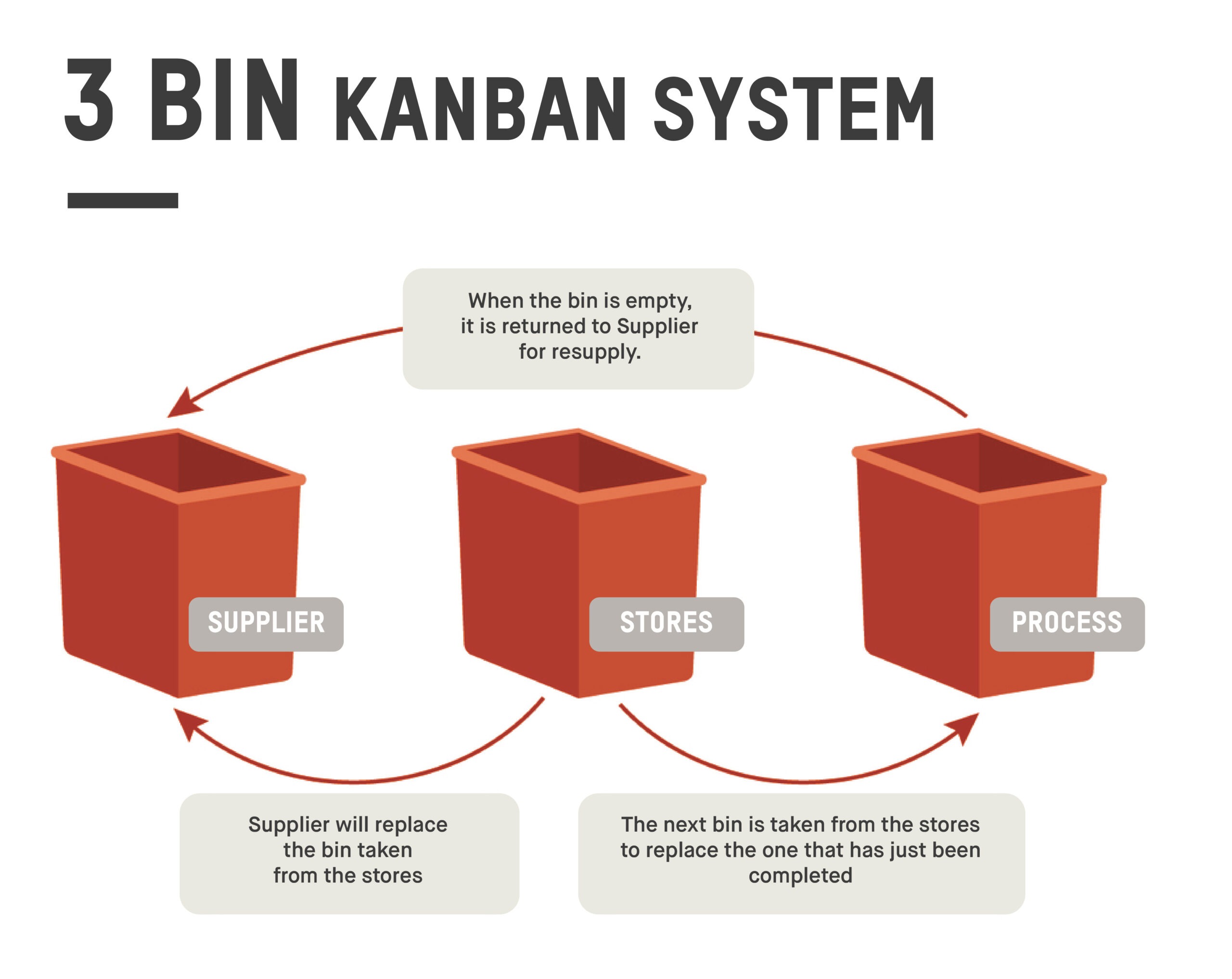

The traditional three-bin kanban system is a good way to optimize circular manufacturing. In this system, there is:

Often linked to the manufacturing processes, this system helps to control inventory at the point of use and ensure steady material flow, both into and out of the different steps of the production chain.

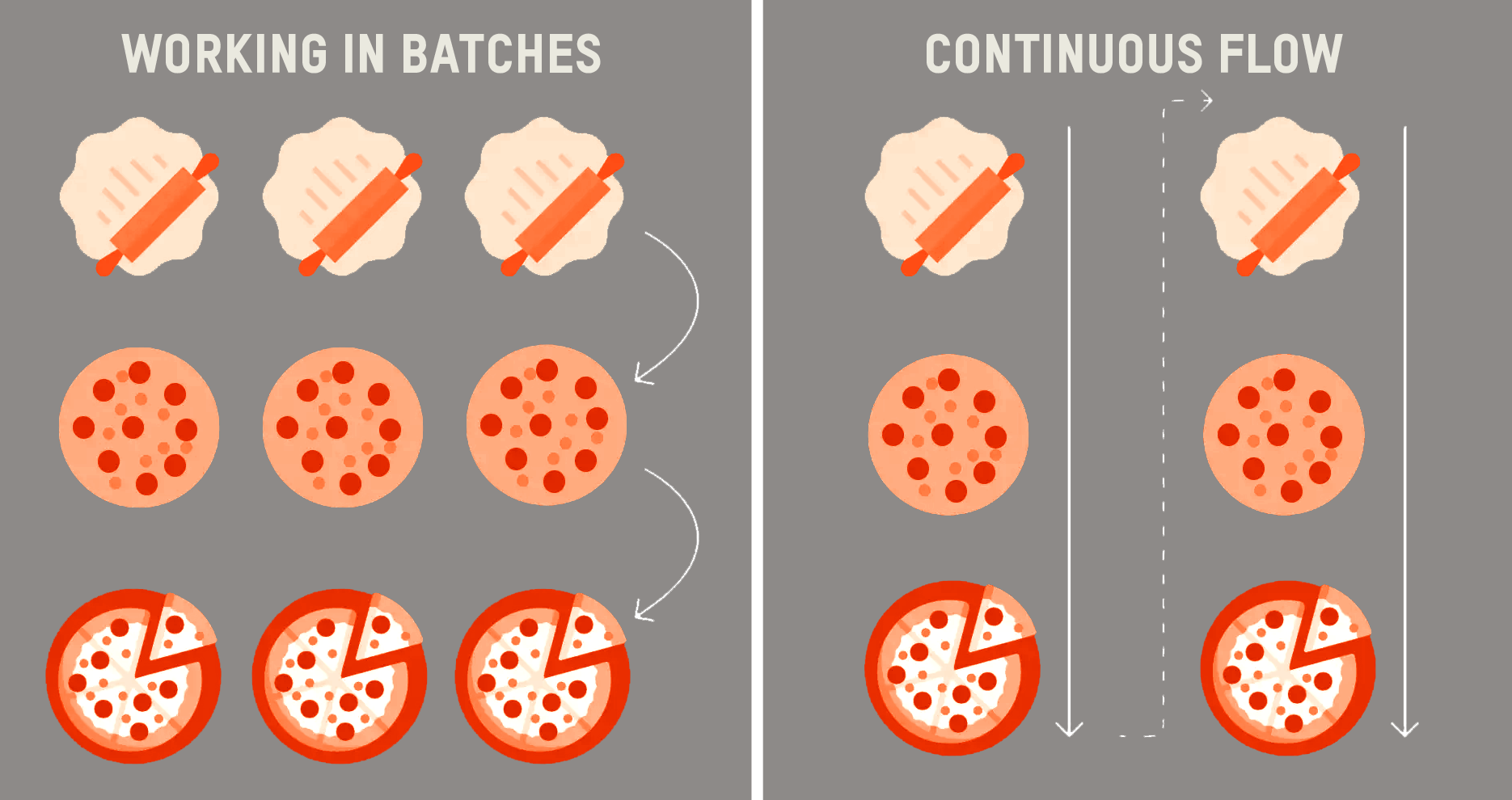

Going back to batch mode is often a reflex when implementing a circular manufacturing system because workers tend to worry they’ll have to deal with interruptions caused by a lack of material or parts.

What many operators don’t realize is that in batch mode, if the material handling system is not optimized, they’ll end up with even more downtime. The challenge will then be to fix the handling system at the same time as the cell.

Either way, material, and material handling have to be synchronized with the change in the cell.

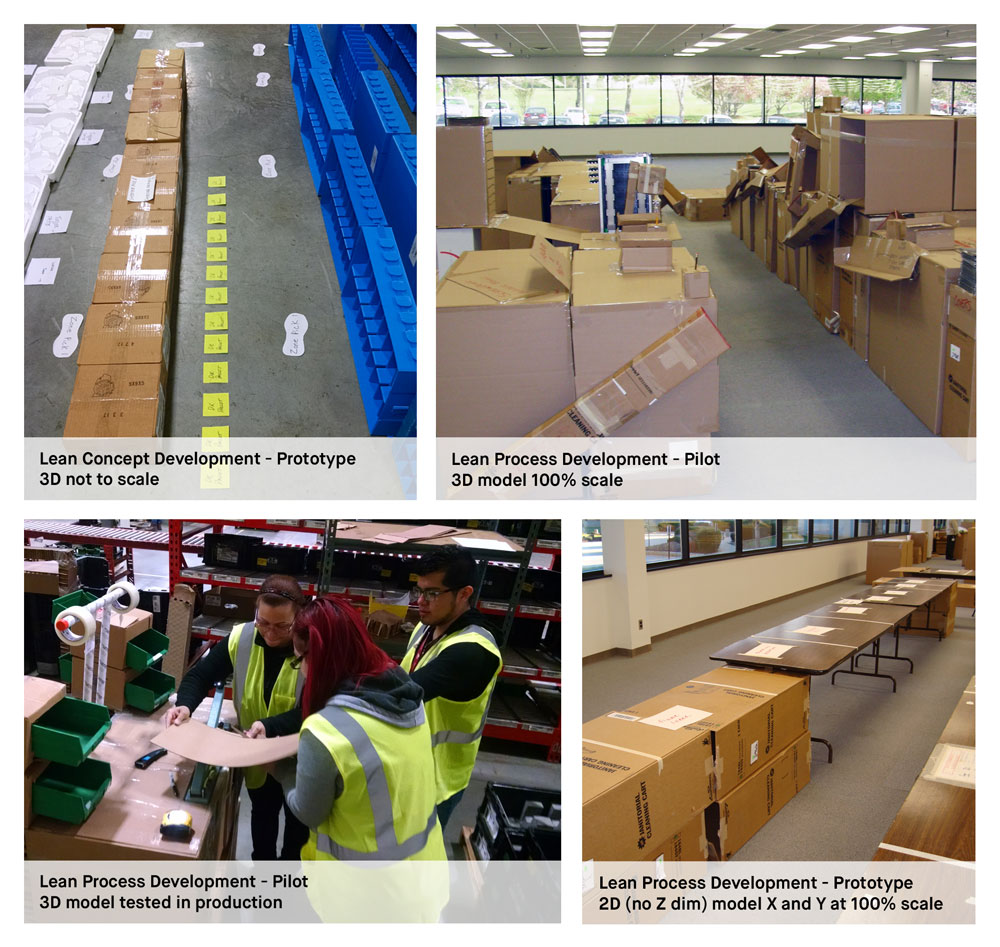

Depending on the technology available and the context, 3 levels of prototyping can be established:

Either way, to facilitate the prototyping process, the best-case scenario is when the equipment is mobile and relatively small so the real pieces can be moved around easily.

Mr. Simonis relates he once visited a manufacturer that had 1800 sewing machines. Because each machine was independent, they were able to move them around easily. They physically changed, tested and adapted the layout with the actual equipment -thanks to the mobile quality of the machines-, which made the process flow a lot easier.

Typically, management fears that implementing the water spider system is going to require a lot more labor -they usually expect that they’ll need twice as many guys!

The best way to prove to them that it won’t be the case is to show them.

Quoting Benjamin Franklin’s vastly imputed saying “Tell Me and I Forget, Teach Me and I May Remember, Involve Me and I Learn”, Mr. Simonis mentions that no matter what the fears are, if you get people to actually try out material handling solutions and options, it solves a lot of problems and answers a lot of questions.

Brainstorming is a good way to start, but trystorming has to follow quickly. Testing out ideas and trying options is the most effective way to determine the best solution for process optimization.

There’s nothing like concrete experience to enhance people’s perspective and creativity. Trystorming can start with dividing the production process into smaller steps, then desiccating the main stages, and finally trying different options and layouts.

Trying out the system and seeing what works and what doesn’t will allow operators to learn more from the designing phase and assimilate the new processes more easily. At a facility level, creating one cell and getting people used to doing it will ensure that they learn from the testing phase.

These steps will allow for the best practice to be put in place, improving the material handling flow and making the circular manufacturing process as efficient as it can be!

Robert H. Simonis is the senior consultant at KCE Consulting LLC. A recognized lean enterprise expert and sought-after speaker and writer, he has over 25 years of experience in automotive, electronics, machining, logistics, and complex assembly operations.

____________________________________________________________________________

Flexpipe Modular industrial pipe racking system can help you with implementing continuous improvement principles. Your team’s creativity can result in a 10% increase in productivity per year. It has been a proven system for more than 50 years now.

See how the modular system improve operational efficiency while saving time in manufacturing processes at Waterax.