Post

WHAT IS THE ROLE OF THE WATERSPIDER IN A LEAN MANUFACTURING STRUCTURE

Post

CIRCULAR MANUFACTURING: THE RULES OF THE CIRCLE

Post

EASY STEPS TO SUCCESSFUL VALUE STREAM MAPPING

The term Karakuri -or Karakuri Kaizen- is derived from the Japanese word meaning machinery or mechanical device used to assist a process with limited (or no) automated resources. Its origins come from the mechanical dolls in Japan that essentially helped lay the foundations of robotics.

Instead of being controlled by software or a computer, the basis of its functionality lies entirely in the overall design of the device. This can range from the simple use of gravity to the use of springs, weights, pendulums, etc.

Many facilities and operations are coming to the conclusion that mechanical automation is the only way to go, as Karakuri Kaizen can provide advantageous and relatively inexpensive solutions that can improve operational processes. This can be achieved by using the “Kaizen” approach, which is based on the idea that the “Kaizen” approach is the only way to improve productivity and reduce costs.

Karakuri is one of the many tools associated with Lean concepts and methodology. Using its fundamentals allows you to dive deeper into business process improvement, but from a cost reduction perspective – it will ultimately allow you to find innovative solutions with a smaller budget. This is why Karakuri Kaizen is commonly used in Lean Manufacturing. Consider this example:

Toyota had identified an inefficient process within its automotive assembly line in which operators were pushing their material/tool carts by hand. This was resulting in lost productivity and an overall extended production cycle time. So Toyota developed a Karakuri-style cart that can be mounted on the car’s engine. Once a car is finished, a weight is released that allows the cart to move to the next vehicle. Toyota also incorporated a tray with parts placed on the fender that allows operators much easier access to materials and tools. Removing non-value-added steps as Toyota has done will progressively reduce process times and allow your operation to produce more, in less time.

Want to know all the ins and outs of building a karakuri structure? Esteban lived the experience and can tell us all about the trials and errors Here is his story

Taking an approach like Toyota, one of the world’s largest automakers, can provide substantial benefits to a facility attempting to move to a more Lean approach. Using Karakuri Kaizen can provide you with the elements necessary to maintain a competitive edge within your industry.

• Cost reduction – As mentioned throughout this article, Karakuri Kaizen enables significant cost reduction in a variety of ways. By reducing production cycle time and lowering automation and overall material costs as processes are optimized, operations will be able to reinvest in themselves more, as their bottom line will be positively impacted.

• Process improvement – In synergy with other Lean concepts, Karakuri reduces the overall cycle time by “automating” the process with a device, instead of relying on manual movement. Like the Toyota example, breaking down the process and locating non-value added steps will help determine which elements would benefit from innovative Karakuri solutions and structures.

• Quality improvement – Process improvement has a direct impact on product improvement. An inefficient production process increases the chances of manufacturing defects and potential errors, so process planning and establishing the most efficient route can only further improve product quality.

• The simplicity of maintenance – Automated systems lead to increased maintenance costs, especially for operations that are almost entirely dependent on their automation. This will usually result in the need for a 24/7 maintenance team in case the system fails – which it inevitably will. Karakuri devices are easy to maintain because of their simplicity and the materials they are made of, so managers don’t have to spend a fortune on a new department and team to keep everything running well.

Karakuri Kaizen provides a beneficial foundation and framework that ensures your production system continues to optimize processes and operational flow. If you are looking to improve operational efficiency, Karakuri is an indispensable tool that will improve performance and enhance the bottom line.

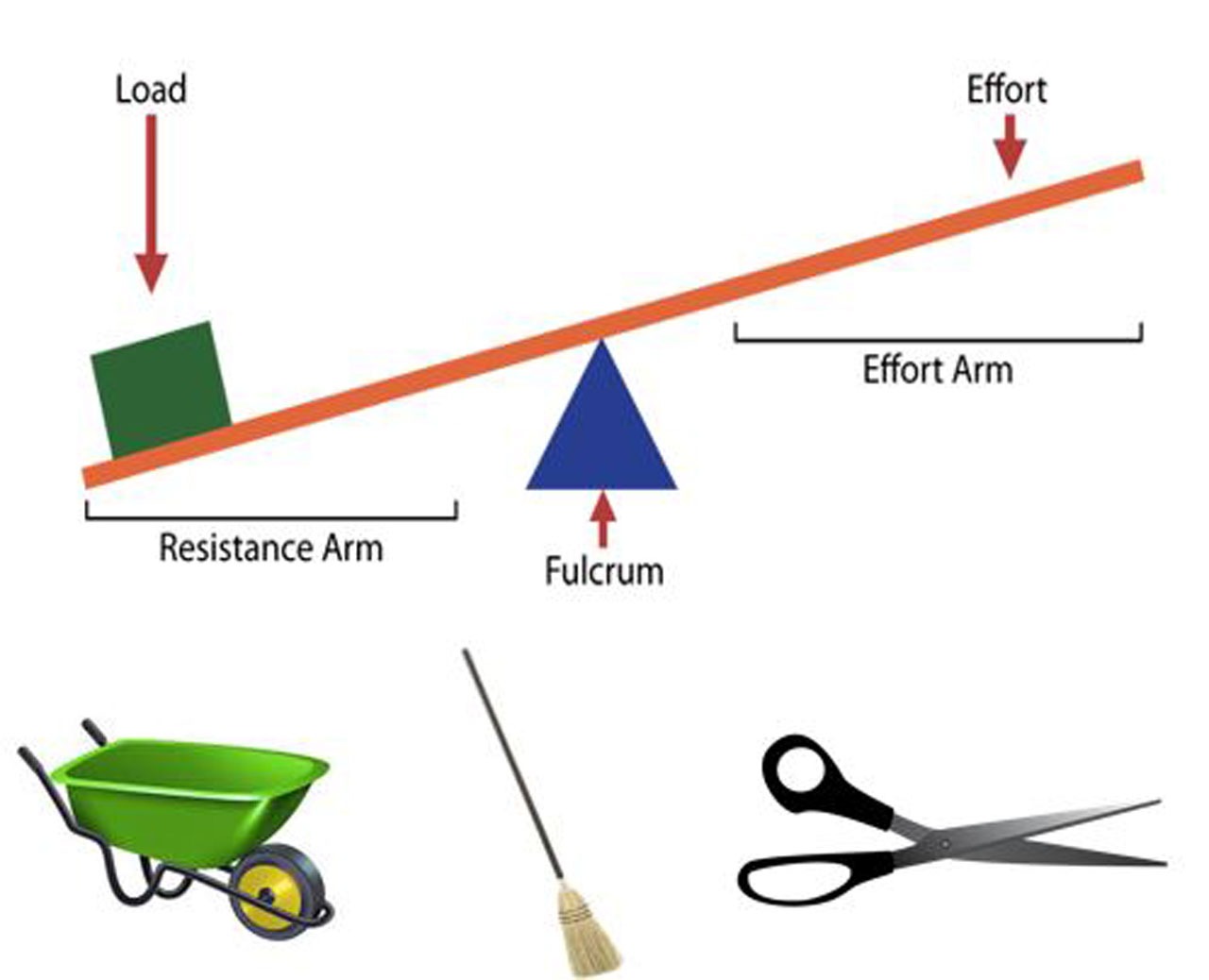

The lever system is a commonly used structure, especially in simple devices. It allows for easy lifting of heavy objects, as it involves a bar moving on a fixed point (the fulcrum) when a force is applied to it.

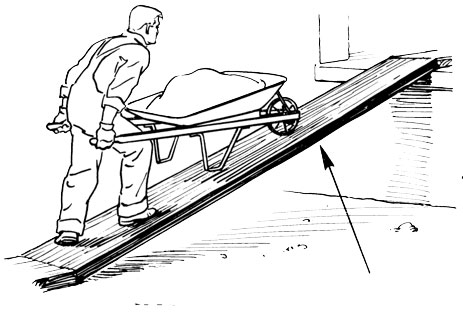

Inclines are everywhere – they are almost impossible to avoid. Sloping roads, hills and ramps are examples of inclines we encounter every day. The incline is a simple but effective way to transport an object on an elevated surface or to use gravity to your advantage to send an object down.

A winch is a device that creates or releases tension on a rope or wire to adjust its length, usually by means of a crank. Winches are commonly used in tugboats, fishing boats, cranes and even rescue helicopters.

The spring is another element frequently used in everyday life by many people. It can be found in a mattress, an enclosure and even in a mouse trap. Springs are made of steel and are available in a variety of designs, including the coil spring. Springs store mechanical energy and release it when a restraining force is removed. One can easily picture a spring when thinking of a retractable pen.

It is said that opposites attract – at least that is the case with magnets. Magnets allow for attraction or repulsion and are another commonly used karakuri-style structure, especially in refrigerators and freezers.

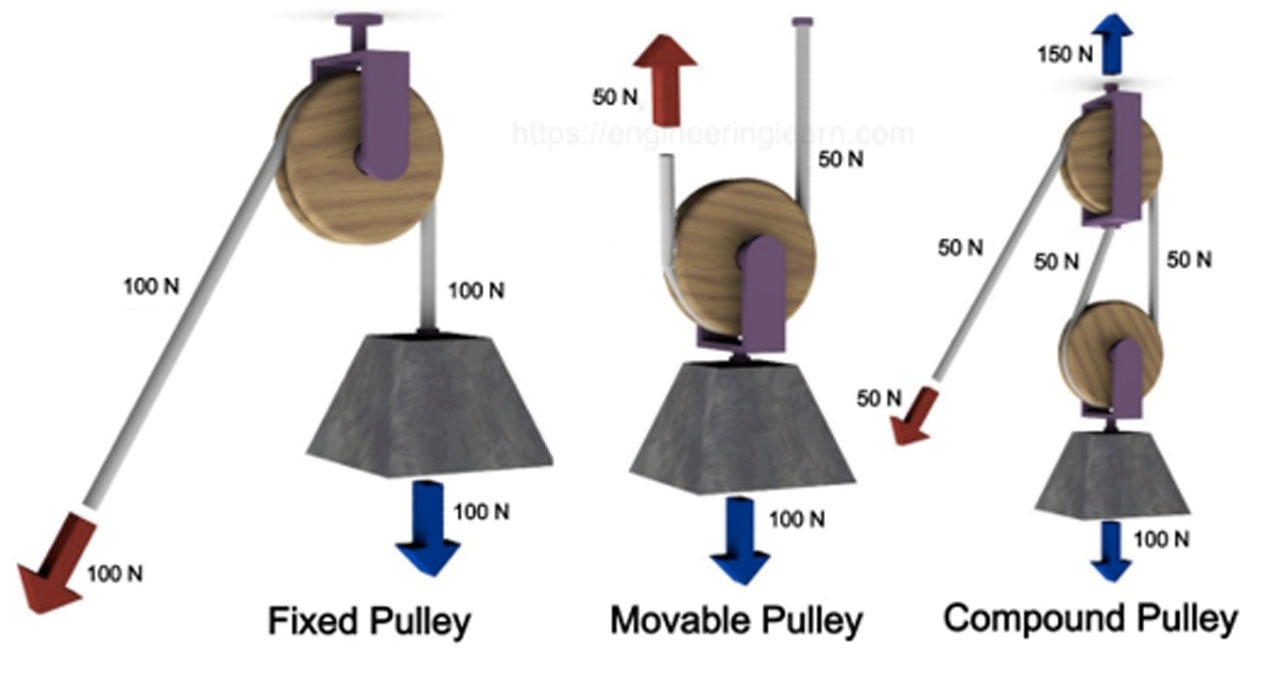

Like the other simple systems on this list, the pulley system was a revolutionary idea used in all types of industries. The pulley involves the use of a rope or cord around a rim, which allows for the transmission of energy and motion. It is especially useful when lifting heavy objects; in this regard, the more pulleys added to the system, the more weight is distributed among them, making it easier for the user.

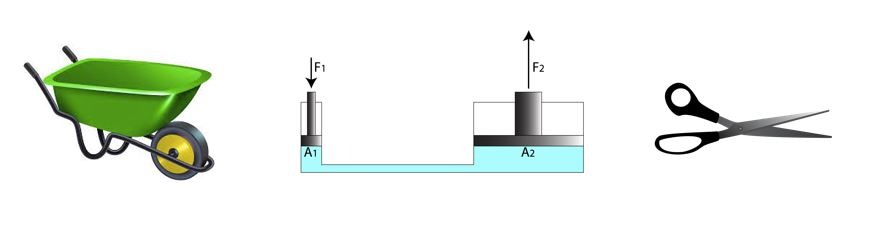

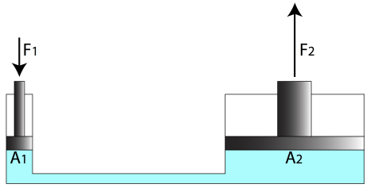

In the visual below, Pascal’s principle demonstrates that a force applied at one point to a liquid in a container is accompanied by equal pressure in all directions. F1 pushes down on A1 in a smaller, more condensed area, but this equal force and pressure will be exerted in A2 and up to F2, thus illustrating the principle.

This principle is widely used in many pieces of equipment such as hydraulic systems, car brakes, barber chairs and a variety of equipment.

Like many other facilities, you may be wondering where to start. Flexpipe offers innovative solutions to your process constraints and understands the importance of having the best equipment available for maximum production efficiency. Our project managers can help you generate ideas and assemblies for your Karakuri structure to take productivity and operational efficiency to the next level. Flexpipe offers innovative solutions to your process constraints and understands the importance of having the best equipment available for maximum production efficiency.Our project managers are able to help you generate ideas and assemblies for your Karakuri structure, to push productivity and operational efficiency to the next level.

You don’t have to spend a small fortune to be operationally efficient. Karakuri structures are simple, innovative solutions that are a must for any team looking for cost-saving solutions. Reduce cycle time, improve processes and production quality by contacting Flexpipe for assistance in designing and building a Karakuri structure for your facility.