Post

10 TIPS TO REDUCE CHANGE RESISTANCE WHEN INTRODUCING LEAN MANUFACTURING

Post

10 THINGS TO KNOW ABOUT MOONSHINE SHOPS

Post

HOW TO DO A 5S AUDIT WITH YOUR SMARTPHONE

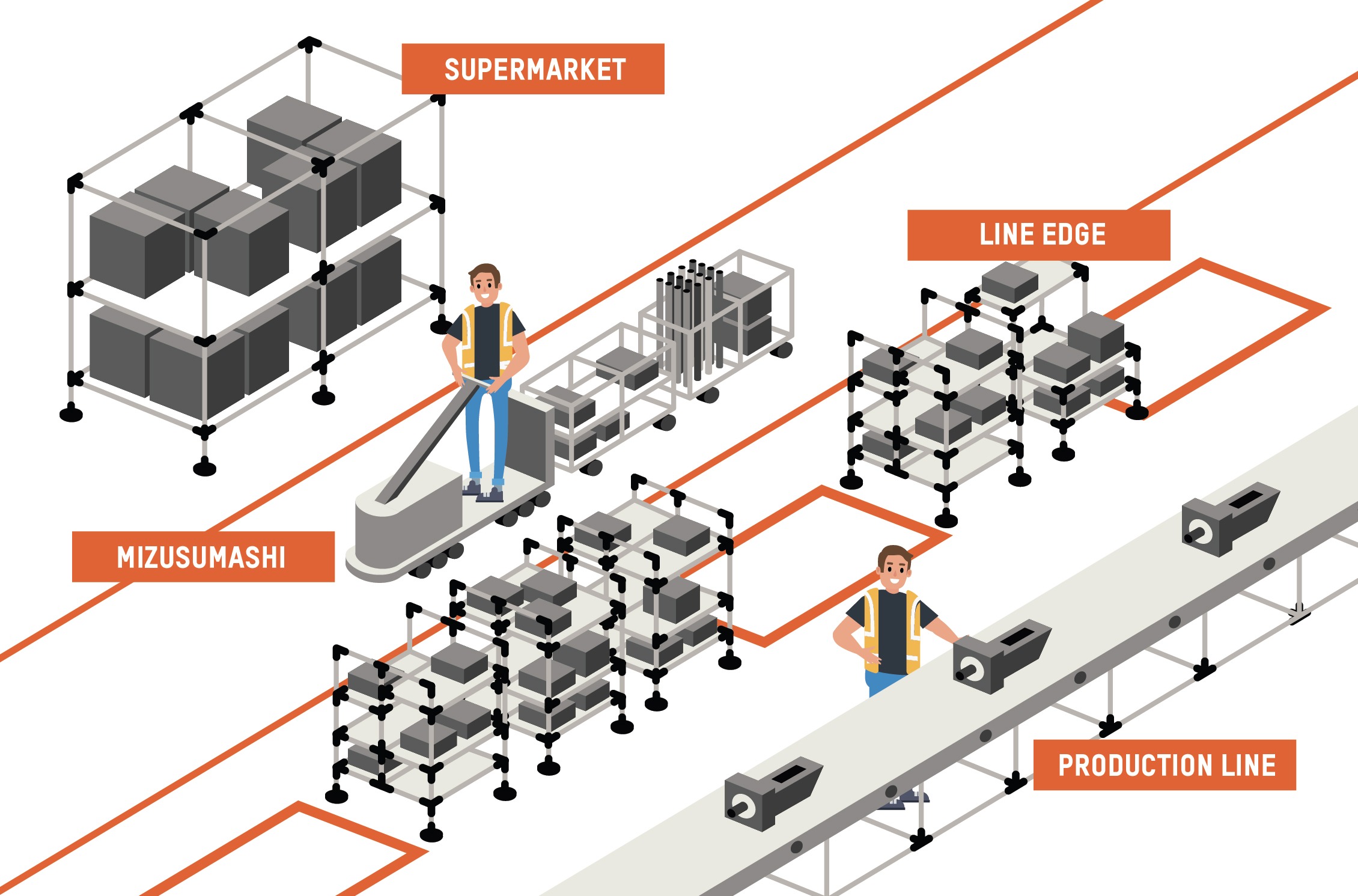

Water spider is a term that refers to a specific person whose main job is to take care of intermittent tasks such as supplying material at workstations.

Like during surgery the assisting person is like a Water Spider, they allow the surgeon to perform the added value task with no distraction.

The rationale behind the water spider in the factory is similar where it allows the rest of the personnel to devote their full attention to added value tasks.

The Water Spider position is often confused with a simple material handler but in a lean manufacturing layout, a Water Spider must be intimate with the process or work cell they support, not just a pick-up-and-drop-off handler.

Water Spider is the go-to person when there is an out-of-cycle task, for example:

Water Spider needs to make sure that the production flow is uninterrupted, and workers are only devote added value tasks.

When a particular worker doesn’t have to take care of auxiliary tasks, they can concentrate on their own productivity. They can become more efficient at adding value.

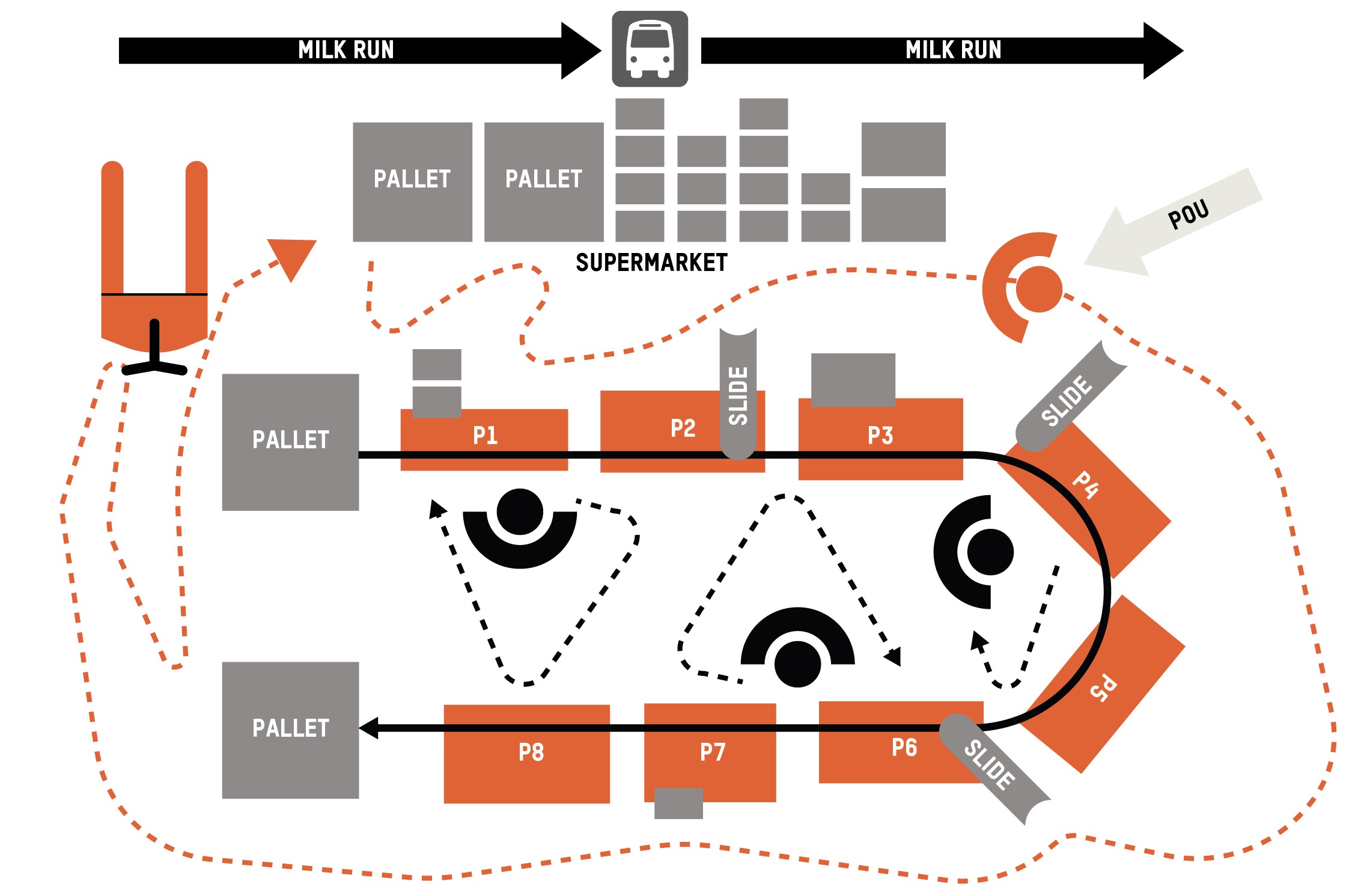

They should visit the workstations and operators in the same order and at similar intervals. The speed and frequency of their rounds should be dictated by the needs of the process.

Water Spider is mizusumashi in Japanese and is often used even in English meaning “make water cleaner” or “purify water”.

Water spiders are representing by Water beetle, notable for their divided eyes and that dives into freshwater but does not stay into water. The water spider dives into the process to get close to the cell, even goes into the cell to do occasional relief work for operators. Specifically, the whirligig beetle is known for their habit of swimming rapidly in circles… and for their gregarious behaviour…and are also notable for their divided eyes which are believed to enable them to see both above and below water”.

And If employees don’t like the name why not using Point of use Provider.

While some floor managers might feel the urge to put a not-so-skilled worker in this position, this is not a good idea:

In order for a water spider to really boost productivity, they need to have a great working understanding of the whole process and need to be able to read the whole workspace.

Here are some important requirements for the job

They should be helpful at every workstation they service, and this requires knowledge of all processes and great work experience.

Learn more on how to maximize productivity with the Andon system. A great way to quickly pinpoint issues at manually operated workstations, improve response time, and reduce downtime is through an Andon system.

Some Senseis say that Water Spider role is a “rite of passage” to becoming a supervisor.

This is why it makes a lot of sense, to treat the position as a way to groom a future team leader, supervisor or manager, instead of a “go-fer” or “catch-all” job.

Read on to learn how a modular pipe handling system helped Hologic increase its productivity by 25%.

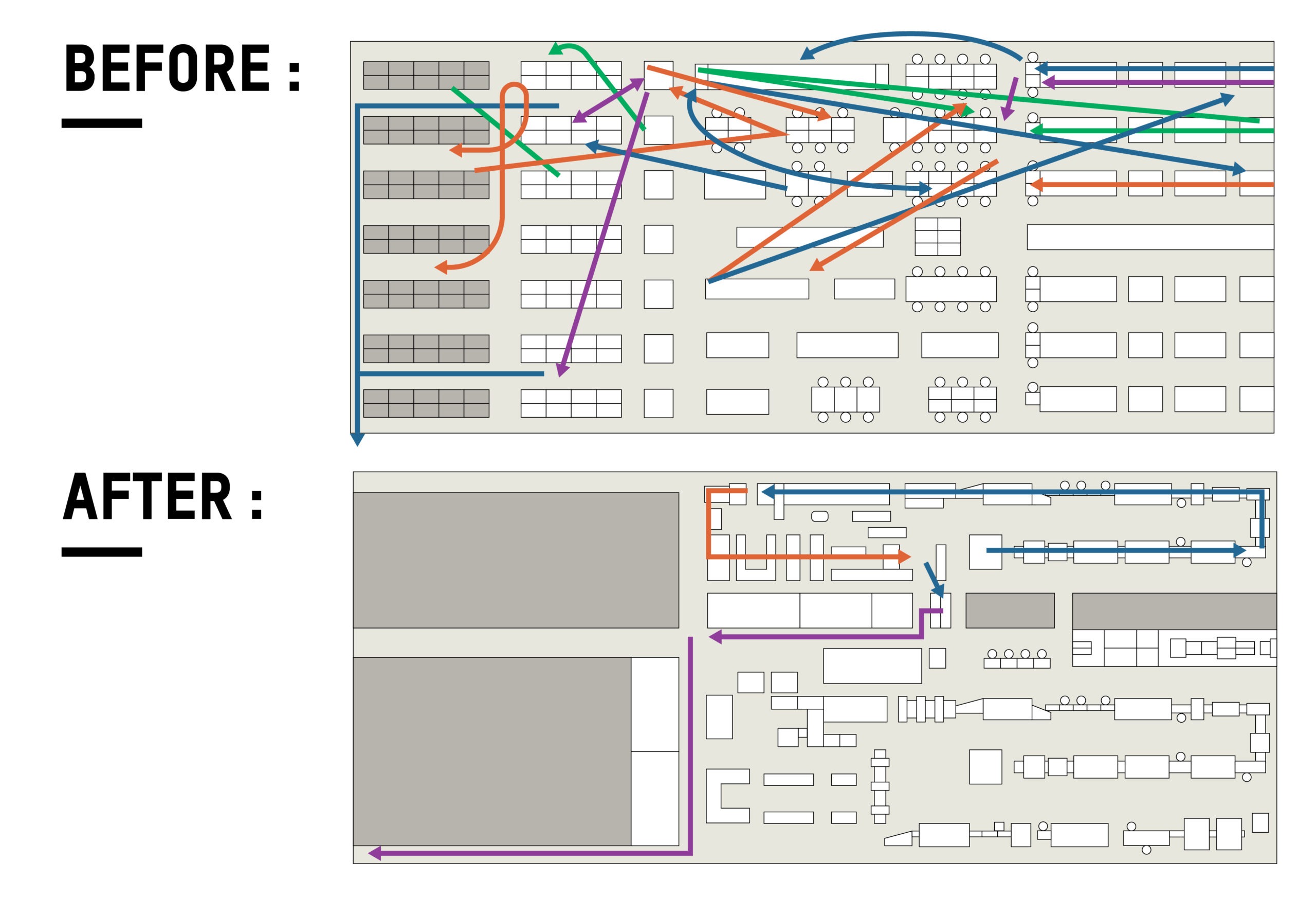

You should be able to see how having a well-functioning water spider can boost overall efficiency and potentially calculate an ROI to present to management. Furthermore, isolating the auxiliary tasks mostly transportation and movement waste in a single place will help to examine them and possibly reduce or eliminate them.

____________________________________________________________________________

Flexpipe Modular industrial pipe racking system can help you with implementing continuous improvement principles. Your team’s creativity can result in a 10% increase in productivity per year. It has been a proven system for more than 50 years now.

See how the modular system improve operational efficiency while saving time in manufacturing processes at Waterax.