When companies think about Kanban, the image of a Kanban board and Kanban cue cards often come to mind. This simple lean manufacturing scheduling system summarizes workflow on a board, showing individual steps required to complete a given project, work, or operation.

The Kanban board is the repository for the Kanban cards. The board outlines a given manufacturing process or defines each stage of a product or project’s step-by-step process. The cards are then placed on the board outlining what tasks need completion.

Aerospace producibility board – Source: planview.com

Cards define what work has been requested, what is currently being worked on, and what work is completed. They represent what remains to be done before moving to the next process step. These cards are also used to outline different ideas and approaches to help move the process along.

The Origins of Kanban

In its simplest form, Kanban is a method of tracking manufacturing workflow or a project’s history. It is a highly effective scheduling method for lean manufacturing, helping to define how much inventory is needed to support current workloads.

Its origins can be traced back to Taiichi Ohno, who – along with Sakichi Toyoda and his son Kiichiro Toyoda – are responsible for developing the Toyota Production System (TPS) and its many lean and continuous improvement methodologies.

Toyota Production System Kanban board. Source: toyota-global.com

Like many lean methodologies emerging from Toyota, Kanban relies upon simple visual cues. The word Kanban is Japanese and literally translates to “card you can see.” It is considered the core tool for managing Just-in-Time (JIT) manufacturing, another lean pillar of TPS. Toyota introduced JIT and Kanban during the 1940s.

JIT is considered a pull system where customer demand is the driving force behind manufacturing. This customer demand essentially “pulls” products to be made, unlike the North American manufacturing processes at that time that relied on pushing products to the market to spur customers to buy those products.

Kanban is seen as an innovation in that it follows similar TPS guidelines; minimizing costs, eliminating waste, and shortening lead times is the best way to add value for customers.

Kanban in Today’s Business Environment

Companies still use Kanban boards and even post-it notes as a convenient replacement for the Kanban cards. Other companies have moved away from this manual process. They have instead adopted digital, SaaS, cloud-based, and mobile-optimized software solutions that provide granular data and up-to-the-instant feedback on workflow and production volumes.

This adoption of real-time platforms has given rise to multiple Ekanban (electronic Kanban) systems that are quickly replacing the visual cue systems of the past. These systems provide invaluable details to line-side operators, managers, project managers, employees, and technicians in manufacturing environments.

Having a system that tracks production data and a project’s progress in real-time is invaluable. It shortens the time it takes to make critical decisions and course corrections. It identifies areas of concern and provides pinpoint accuracy on issues that impact workflow. It allows companies to determine when inventory needs replenishment to keep up with demand.

Ekanban systems can be accessed from any laptop, mobile phone, or desktop with an internet or Wifi connection. This means designated employees can easily track production throughput no matter where or when they work. Employees no longer have to view the Kanban board to get a breakdown of production throughput, and nobody has to spend any time updating that board. Instead, everyone merely accesses the information on their own.

Simple, Scalable, and Modular EKanban Systems

One of the drawbacks for manufacturers is the cost of fully implementing an Ekanban system alongside its existing software, like Enterprise Resource Planning (ERP), Material Requirements Planning (MPR), and other production or inventory management systems. However, like Flexpipe’s tube and joint system, there are modular and scalable solutions that allow you to gradually introduce EKanban without breaking the bank.

Steute Technology’s NEXY Digital Shop Floor Solution is one of these modular and scalable systems. Rob Hargis of Steute USA outlines some simple ways the company’s Ekanban system works.

Watch Ian Johnson from Flexpipe and Rob Hargis of Steute USA outlining some simple ways the NEXY Digital Shop Floor Ekanban’s system is working.

https://youtu.be/9HfLjpqFenE

1. What is the NEXY Digital Shop Floor Solution?

Simply put, NEXY is an industrial wireless solution that streamlines the inventory replenishment process by leveraging Steute Technology’s wireless sensor technology.

NEXY’s flow rack sensor is a robust, sturdy, and easy-to-install device that fits easily on any Flexpipe Flow Rack. It operates at 915 MHz, so it doesn’t interfere with other WiFi signals. This is especially important given the number of Wifi sources on today’s production floors.

The flow rack sensor easily snaps in pace on any roller and does away with operators using barcode/RFI scanners to register inventory at a given work cell.

2. What are the Main Benefits?

One common source of waste in manufacturing includes inventory replenishment. In a lean manufacturing work cell, this often involves an operator leaving the cell, walking to inventory, waiting to get the parts, consumables, or materials they need, and then walking back to their work cell. This is all wasted time.

The further the inventory is away from the lean cell, the longer the transit times and the more time is wasted. Some companies ignore this wasted time. However, calculating how often a given work cell needs replenishment each day, week, or month and how many cells are on the shop floor quickly amounts to a considerable amount of motion waste and non-value tasks.

Water Spider is the go-to person who can make the bridge between the lean cell and the supermarket.

In other instances, operators must go outside the cell to register the inventory with an RFID/barcode scanner. Again, depending on how often the replenishment occurs, this time quickly adds up. For cells with high inventory replenishment throughout the day, this wastes time and ultimately affects production throughput for a single cell.

Even companies that still use the manual Kanban processes on a Kanban board with Kanban cards can save considerable time and achieve significant cost reductions with NEXY. Operators can stay in the cell and focus on completing work tasks while NEXY operates behind the scenes.

No more time filling out Kanban cards or updating Kanban boards. No need for RFID/barcode scanners. No need to leave the work cell to replenish inventory. No more long transit times walking to and from inventory/stores.

No RFID/barcode scanners

No time wasted on inventory replenishment

No Wifi interference

No Noise (low sound always)

No more manual Kanban cards and Kanban Boards

“Everything is done behind the scenes. All the operator or employee has to do is focus on their work. They will never notice when inventory is replaced.”

3. Where is the Data Stored?

Once actuated, the flow rack sensor immediately sends wireless signals to Steute Technology’s access point. From there, the access point sends the data to the sensor bridge – a Programmable Logic Controller (PLC) housed in a cabinet on the shop floor.

The PLC then takes all the data and creates an Application Programming Interface (API), which can either be sent to a shop floor server or a cloud-based server. The wireless solution is 128-bit encrypted and works with multiple IT cyber-security protocols.

Wireless tilting sensor RF RW-NET

sWave.NET® wireless technology

eKanban software module

Sensor Bridge

4. How Easy is it to get Started?

The simplicity of NEXY is that companies alone decide how much to buy and when. The system isn’t dependent upon immediate adoption across a company’s shop floor. Companies can start small, learn, improve, and then progress at their own pace adding new flow rack sensors and increasing scalability when they see fit.

“Getting up and running is easy. Customers who buy Flexpipe Flow Racks simply reach out to Flexpipe, and we’ll get involved… We start with a simple consultation to determine their needs and current process and then discuss their goals. After that, it’s simply a matter of doing what the customer asks.”

A Simple Solution to Ease Into Manufacturing 4.0

Nowadays, every manufacturer has heard of “manufacturing 4.0” or “industry 4.0.” Both are the same thing. They simply refer to The Fourth Industrial Revolution, the adoption of automated technologies, and their synchronization with digital data solutions and networks.

The first industrial revolution used water and steam to power machines and equipment. The second included improved communication with the telegraph and the installation of railway lines to transport materials and products. The third occurred during the 1950s with the early adoption of digital solutions that improved communication.

The fourth is simply a natural progression from the third; improved digital solutions linked to automated and robotic equipment ensure a steady stream of real-time data.

NEXY is the simplest way for a manufacturer to be introduced to this all-important fourth industrial revolution. This is especially the case for labor-intensive manufacturers who want to manage their transition at their own pace.

Get the best free plan to build your next Kanban rack

Kanban station

Download this free plan

Flat pipe Kanban rack

Download this free plan

Storage out Kanban rack

Download this free plan

Kanban gravity flow rack

Download this free plan

Rob Hargis

Rob Hargis is a seasoned Brand Manager with the NEXY division of Steute Technologies, providing wireless eKanban, Andon, and AGV integrated sensor networks for manufacturing, assembly and industrial workflow processes in automotive, white goods, and other complex-assembly environments.

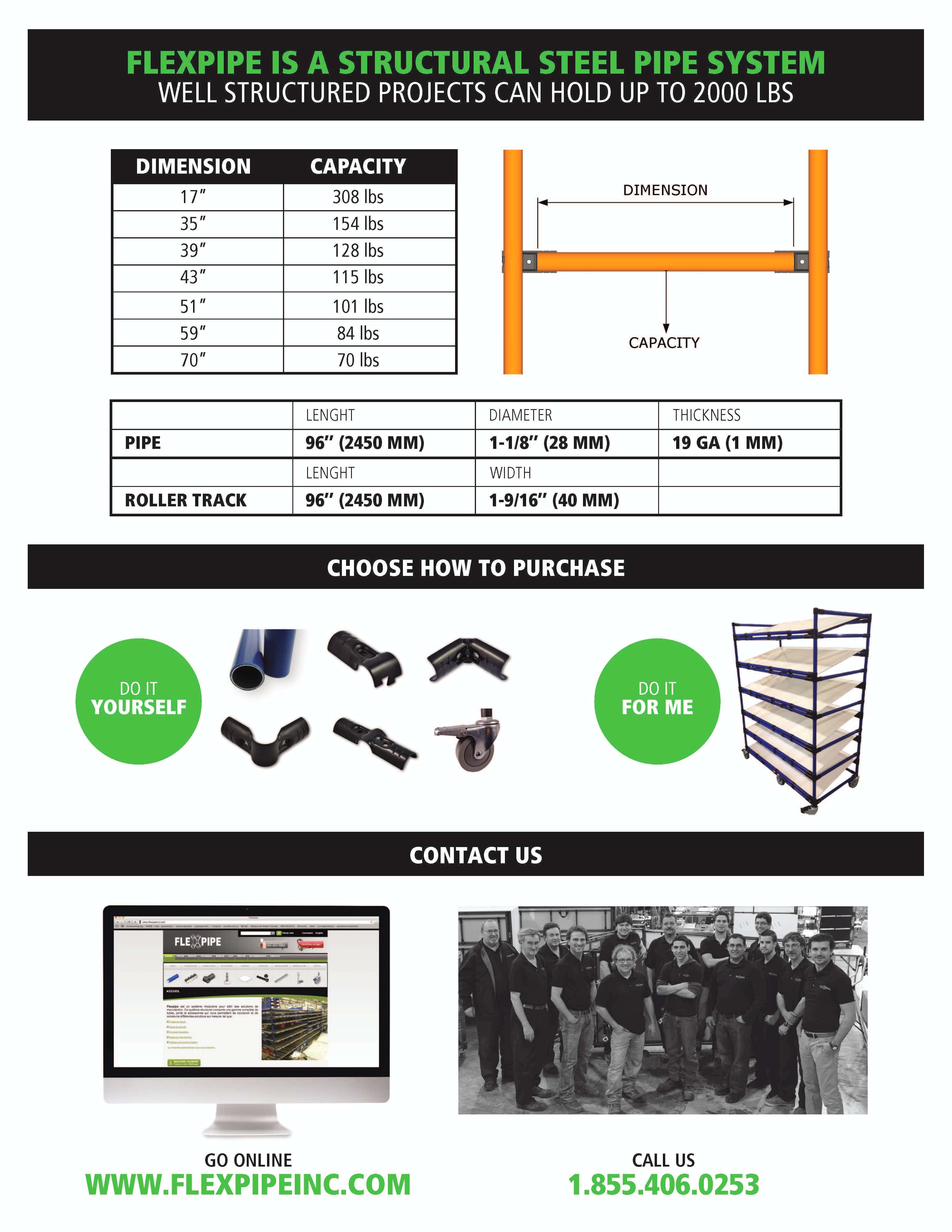

Modular, Scalable, and Affordable Material Handling with Flexpipe

Flexpipe is an innovator, supplier, and designer of modular and scalable steel tubes and joints that help companies reduce material handling costs. Based out of Montreal, the company provides multiple products, training, and insight to companies wanting to adopt lean manufacturing.

The company offers a full-service solution that includes its free software add-on SketchUp, multiple outlines and assembly designs, and design and cutting services to help companies build their own material handling structures and reduce costs.

If you would like to see how Flexpipe can help, contact us now.