We can all agree that organizing increases productivity. Many types of industries can benefit from the integration of modular drawers. Drawers create a well-organized lean manufacturing workspace that can optimize space. They are a great solution for parts and product management. Fully customizable, they have become essential for any business wishing to increase storage while reducing the footprint.

Estimated reading time: 8 minutes

1-2h

1-2hHere are a few of the many industries that can benefit from the use of modular drawers:

- Aerospace – Aviation calls for absolute protection of valuable parts. Safely store these parts incorporating drawers into your pipe and joint structures.

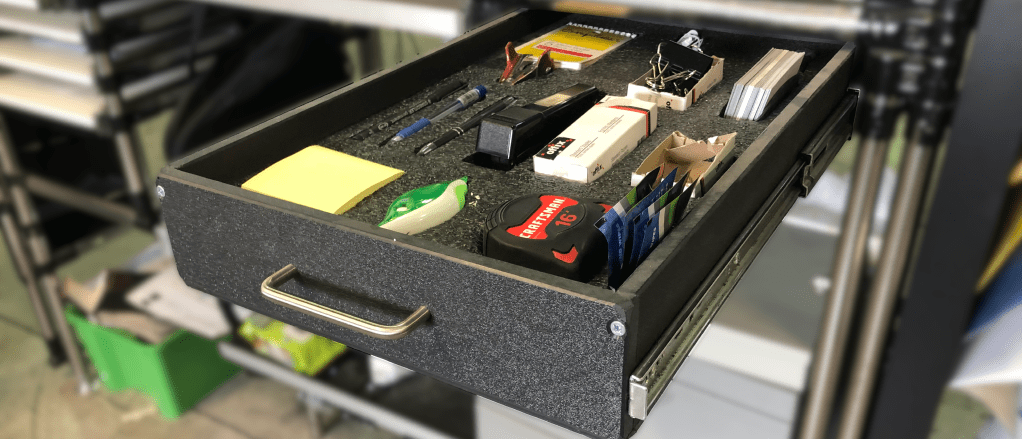

- Automotive – Avoid the hassle of always looking for tools by creating a system where everything has a place, and everyone knows where to find it.

- Packaging – Regardless of the product, there will always be equipment, materials and or parts of different sizes that will need storage, make it efficient and well organized.

Benefits of using drawers:

- Protection while transporting

- Easy access

- Customizable storage solutions

- Comfort and ergonomics

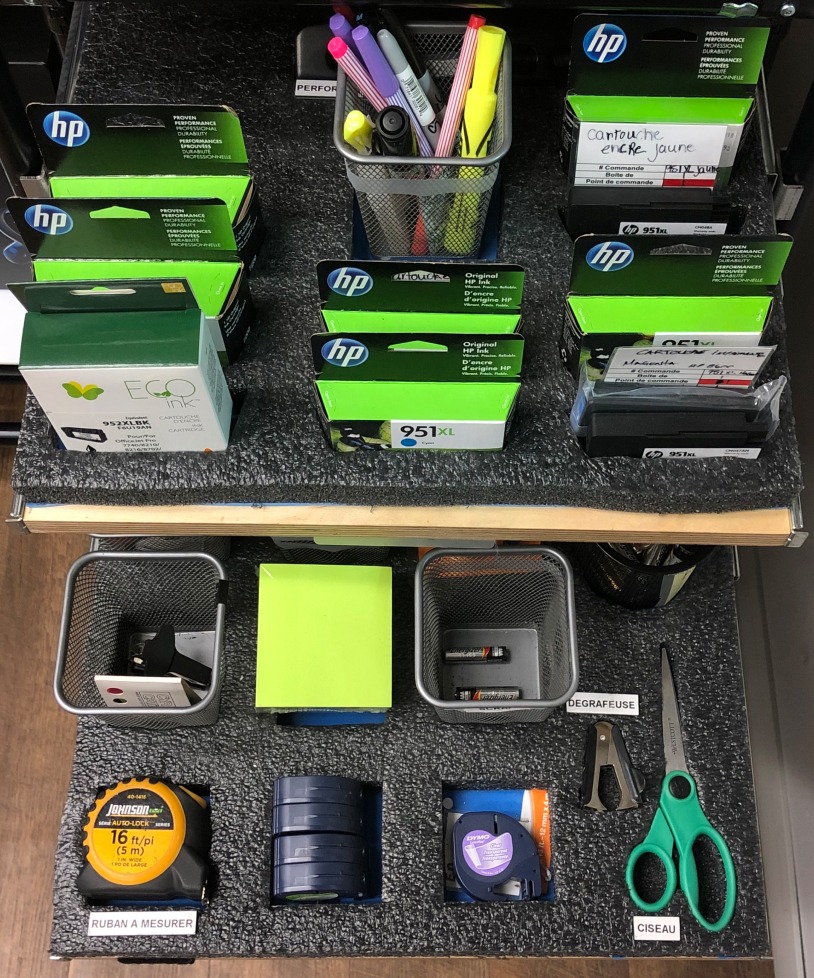

- Inventory management

Tips to remember:

- Determine what it is intended for, to evaluate the space needed

- Think ergonomics, consider heights

- If using multiple drawers, use labels to identify

- Prioritize top drawer, reserve for tools or parts that are the foundation of the task

- Use dividers to micro-organize drawer space

What you need to complete the project

Define what type of drawer and surface to use

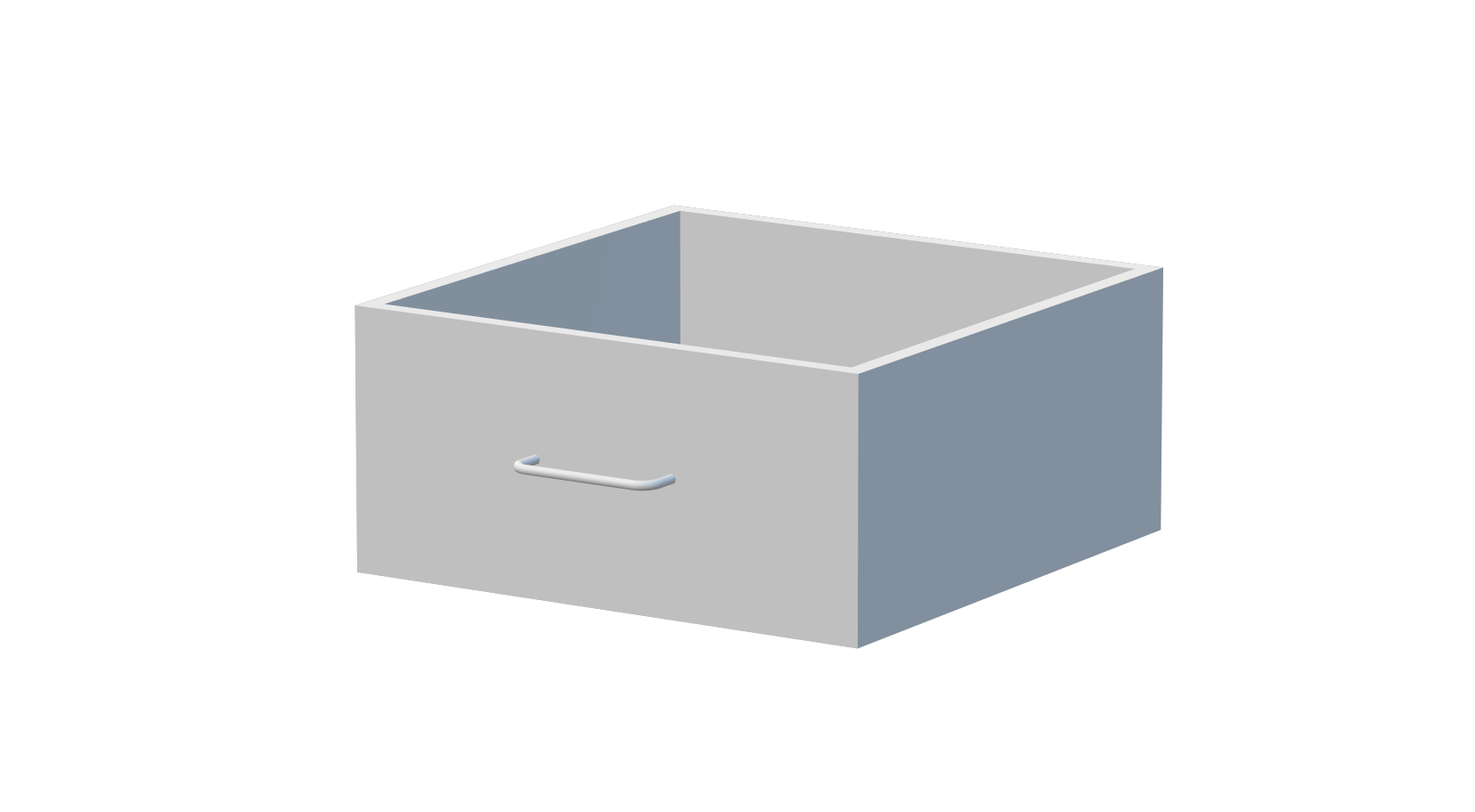

Box Drawer:

We recommend using a 1/2″ HDPE plastic surface or thicker when building box drawers

Pipe and Joint Drawer:

If using a thin surface such as 1/4″ HDPE surface with this setup, make sure to add enough support in the middle of your drawer frame

Choose drawer slide and accessories

Our standards are ACCURIDE Full-Extension 14″ 20″ and 24″ lengths

Full-extension allows drawer to open the full length of the slide, allowing for greater access

FL-COU-U: slide bracket to stabilize drawers on pipe and joint structure

F-A85/8: Self-tap metal screw to fix drawer slides to structure

F-S81/2: Screw used to fix guide rail to drawer sides

F-SF81: Screw used to assemble box drawer

AO-SHIM: to level any surface

Helpful Videos:

Take it to the next level